Preparation method of a lithium battery

A lithium battery and negative electrode material technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of low battery specific capacity and poor cycle performance, and achieve simple preparation process, low discharge platform and high production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

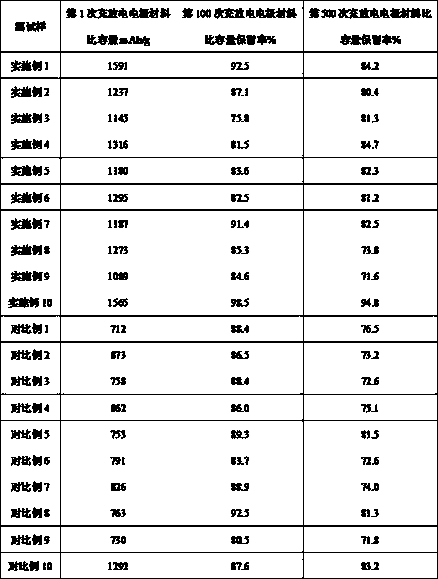

Examples

Embodiment 1

[0013] Weigh 0.4gFe 2 o 3 / CoS-AC negative electrode material is mixed with 0.05g polyvinylidene fluoride, 2ml of N-methylpyrrolidone is added dropwise, stirred and mixed evenly to form a slurry. Coat the slurry evenly on the copper foil, dry it in vacuum at 120°C for 10min, punch it into a circular negative electrode sheet with a diameter of 14mm, dry it in vacuum at 85°C for 24h, and assemble it into a 2016-type battery in a glove box filled with argon. Lithium sheet is used as the counter electrode, Celgard2400 polypropylene diaphragm is used as the diaphragm, and the electrolyte is 1mol / l LiPF6 mixed with ethylene carbonate EC / dimethyl carbonate DMC / diethyl carbonate EMC solution (volume ratio is 1:1:1), Add the electrolyte dropwise until the separator, positive and negative electrodes are fully wetted,

[0014] where Fe 2 o 3 / CoS-AC anode material preparation method is as follows:

[0015] 1) Add 48 parts by weight of cobalt nitrate hexahydrate, 200 parts by weight ...

Embodiment 2

[0020] Exactly the same as Example 1, the difference is: add 54 parts by weight of cobalt nitrate hexahydrate and 10 parts by weight of Fe 3 o 4 / SiO 2 / NiO 2 composite material.

Embodiment 3

[0022] Exactly the same as Example 1, the difference is: add 42 parts by weight of cobalt nitrate hexahydrate and 18 parts by weight of Fe 3 o 4 / SiO 2 / NiO 2 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com