Separation and enrichment method for lithium isotopes

A technology for separation and enrichment of lithium isotopes, applied in the separation of different isotopic elements, separation methods, separation of dispersed particles, etc., can solve the problems of retention, limited efficiency of separation and enrichment, and inability to perform extraction and separation, and achieve the effect of separation and enrichment Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, a three-stage cascaded cross-flow separation operation is carried out, that is, the operation of "extraction-burning-water dissolution" is carried out three times.

[0066] First level:

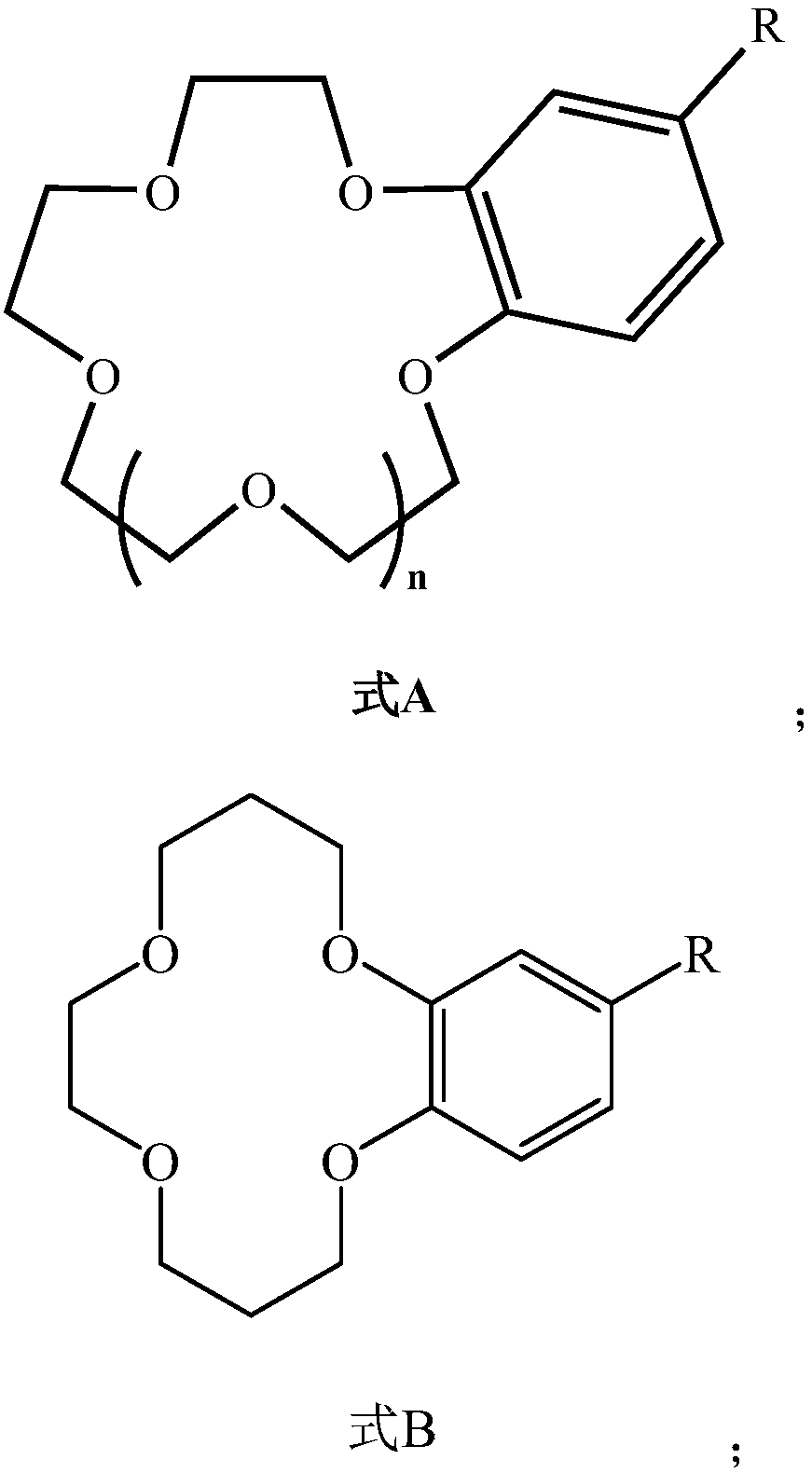

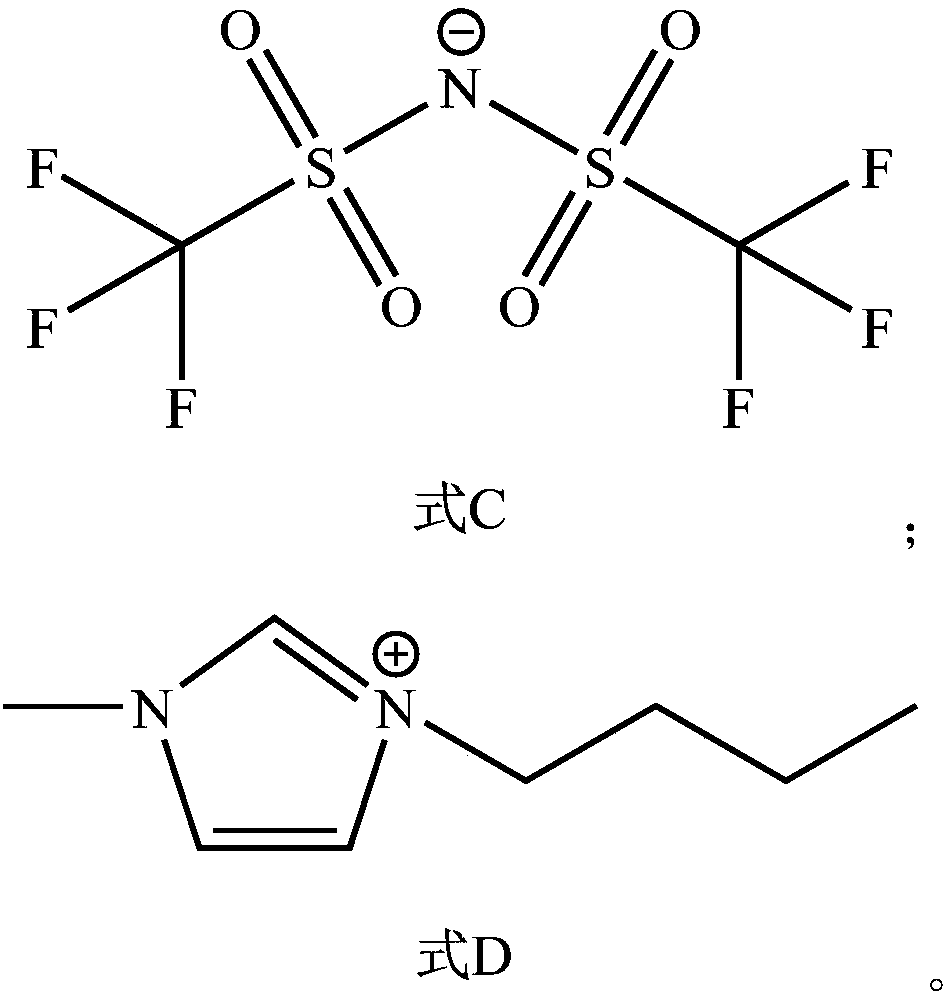

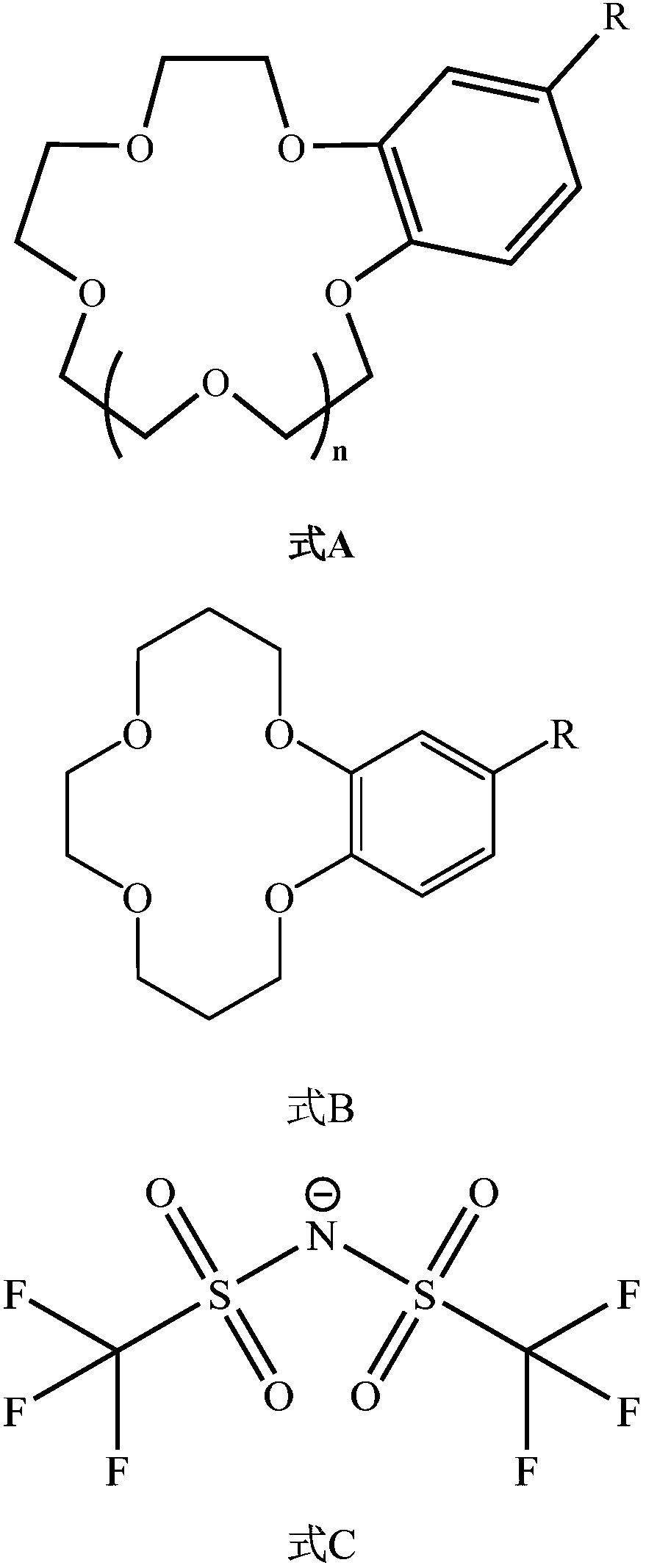

[0067] First add 7mL of the extracted aqueous phase (0.5mol / L lithium chloride solution) to a 50mL centrifuge tube with a pipette gun, then add 7mL of the extracted organic phase (extractant is benzo-15-crown-5 (B15C5) , The hydrophobic ionic liquid is 1-ethyl-3-methylimidazole bistrifluoromethanesulfonylimide salt ([EMIm][NTf 2 ]), the diluent is anisole, the concentration of the extractant is 0.05mol / L, and the volume ratio of the hydrophobic ionic liquid to the diluent is 3:7), placed on a constant temperature shaker for 40 minutes, and transferred The two phases were completely separated on a high-speed centrifuge to obtain the first loaded organic phase and the first raffinate.

[0068] Transfer the first loaded organic phase to a platinum crucible, and place...

Embodiment 2

[0079] In this embodiment, a three-stage cascaded cross-flow separation operation is carried out, that is, the operation of "extraction-burning-water dissolution" is carried out three times.

[0080] First level:

[0081] First add 10mL of extracted aqueous phase (2mol / L lithium chloride solution) to a 50mL centrifuge tube with a pipette gun, then add 10mL of extracted organic phase (extractant is benzo-15-crown-5, hydrophobic ion The liquid is 1-butyl-3-methylimidazole bistrifluoromethanesulfonimide salt ([BMIm][NTf 2 ]), the diluent is anisole, the concentration of the extractant is 0.4mol / L, and the volume ratio of the hydrophobic ionic liquid to the diluent is 2:3), placed on a constant temperature shaker for 60 minutes, and transferred The two phases were completely separated on a high-speed centrifuge to obtain the first loaded organic phase and the first raffinate.

[0082] Transfer the first loaded organic phase to a platinum crucible, and place it in a muffle furnac...

Embodiment 3

[0093] In this embodiment, a five-stage cascaded cross-flow separation operation is carried out, that is, the operation of "extraction-burning-water dissolution" is carried out five times.

[0094] First level:

[0095] First add 10mL of extracted aqueous phase (3mol / L lithium iodide solution) to a 50mL centrifuge tube with a pipette gun, then add 10mL of extracted organic phase (extractant is benzo-15-crown-5, hydrophobic ion Liquid is 1-ethyl-3-methylimidazole bistrifluoromethanesulfonylimide salt, diluent is anisole, the concentration of extractant is 0.5mol / L, and the volume ratio of hydrophobic ionic liquid and diluent is 1:4), placed on a constant temperature shaker for 60 min, and transferred to a high-speed centrifuge after the shake was completed to completely separate the two phases to obtain the first loaded organic phase and the first raffinate.

[0096] Transfer the first loaded organic phase to a platinum crucible, and place it in a muffle furnace for burning; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com