Preparation of copper and cobalt codoped manganese-based catalyst and application of catalyst to low-concentration ozonolysis

An ozone decomposition and catalyst technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve the problem of insufficient stable performance, short service life and moisture resistance of ozone decomposition catalysts. It can improve catalytic activity and water resistance, long service life and strong moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

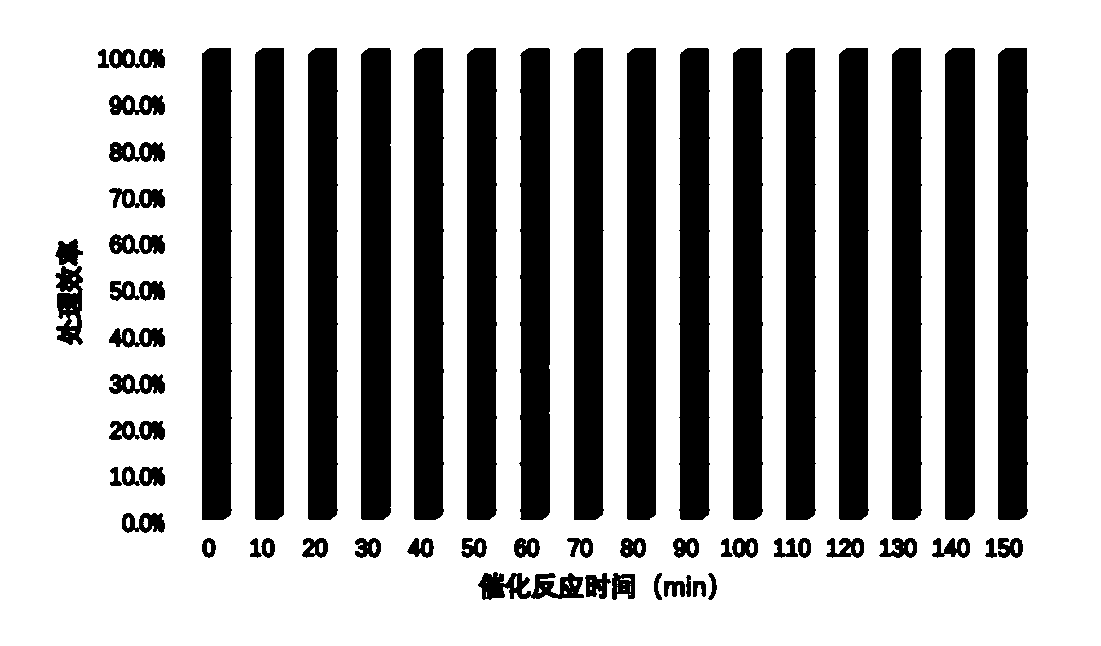

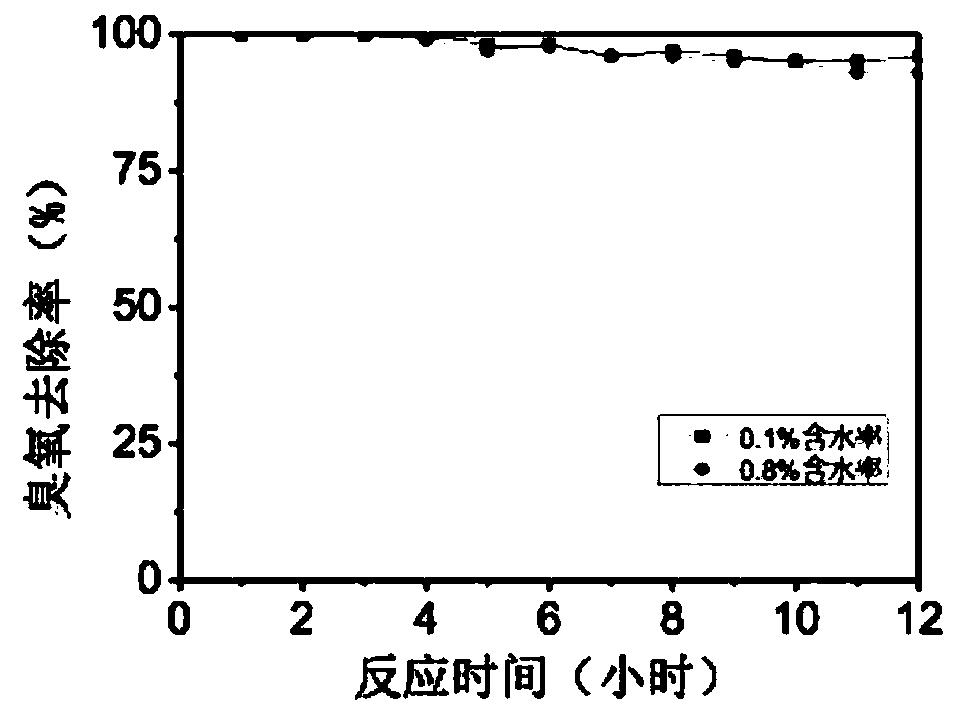

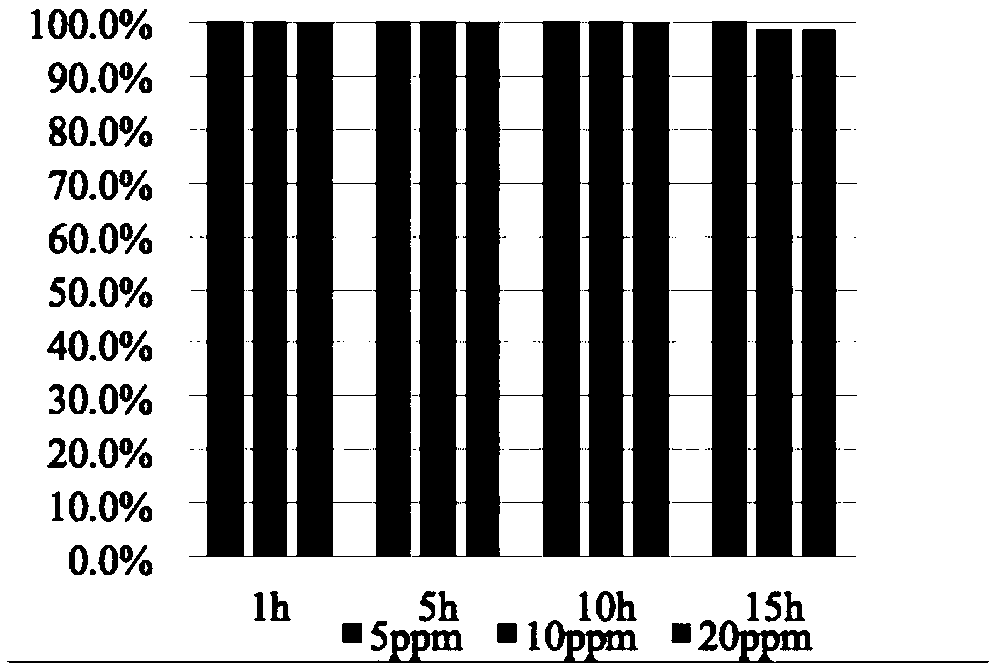

[0019] Dissolve 0.948g of potassium permanganate in 30mL of deionized water and stir for 30min to form homogeneous phase A. Dissolve 2.208 g of manganese acetate in 30 mL of deionized water and stir for 30 min to form a homogeneous phase B. Then in the state of continuous stirring, liquid A and liquid B are uniformly mixed, and then 0.0192g of copper nitrate solid and 0.0291g of cobalt nitrate solid are added to the above-mentioned homogeneously mixed solution, and after ultrasonic dissolution is complete, they are transferred to a 150mL hydrothermal reactor, The temperature was 140° C. for 2 hours, and cooled naturally after the reaction. The precipitate was obtained by centrifugation, washed several times with deionized water and dried overnight. Then put the catalyst material in 2mol / L nitric acid for acid treatment for 15min, and dry it for later use. Add 1ml of PTFE emulsion (60%) to deionized water at a ratio of 1:30, then add 200mg of the above-mentioned catalyst powd...

Embodiment 2

[0021] Dissolve 1.58g of potassium permanganate in 50mL of deionized water and stir for 30min to form homogeneous phase A. Dissolve 3.68g of manganese acetate in 50mL of deionized water and stir for 30min to form a homogeneous phase B. Then, in the state of continuous stirring, liquid A and liquid B are uniformly mixed, and then 0.032 g of copper nitrate solid and 0.05 g of cobalt nitrate solid are added to the uniformly mixed solution, and after ultrasonic dissolution is complete, they are transferred to a 150 mL hydrothermal reaction kettle. The temperature was 140° C. for 2 hours, and cooled naturally after the reaction. The precipitate was obtained by centrifugation, washed several times with deionized water and dried overnight. Then put the catalyst material in 5mol / L nitric acid for acid treatment for 15min, and dry it for later use. Add 1ml of PTFE emulsion (60%) to deionized water at a ratio of 1:30, then add 200mg of the above-mentioned catalyst powder to the dilute...

Embodiment 3

[0023] Dissolve 1.58g of potassium permanganate in 50mL of deionized water and stir for 30min to form homogeneous phase A. Dissolve 3.68g of manganese acetate in 50mL of deionized water and stir for 30min to form a homogeneous phase B. Then, in the state of continuous stirring, liquid A and liquid B are uniformly mixed, and then 0.032 g of copper nitrate solid and 0.05 g of cobalt nitrate solid are added to the uniformly mixed solution, and after ultrasonic dissolution is complete, they are transferred to a 150 mL hydrothermal reaction kettle. The temperature was 160°C for 4 hours, and cooled naturally after the reaction. The precipitate was obtained by centrifugation, washed several times with deionized water and dried overnight. Then put the catalyst material in 2mol / L hydrochloric acid for acid treatment for 30min, and dry it for later use. Add 1ml of PTFE emulsion (60%) to deionized water at a ratio of 1:30, then add 200mg of the above-mentioned catalyst powder to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com