Preparation method of CoFe2O4 nano particle

A kind of nanoparticle, No. 1 technology, applied in the field of CoFe2O4 nanoparticle preparation, can solve the problems that affect the preparation efficiency of carboxylated cobalt ferrite magnetic nanoparticles, poor water dispersion effect, low combustion furnace efficiency, etc., to improve combustion efficiency and Combustion quality, high reliability, effect of reducing outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

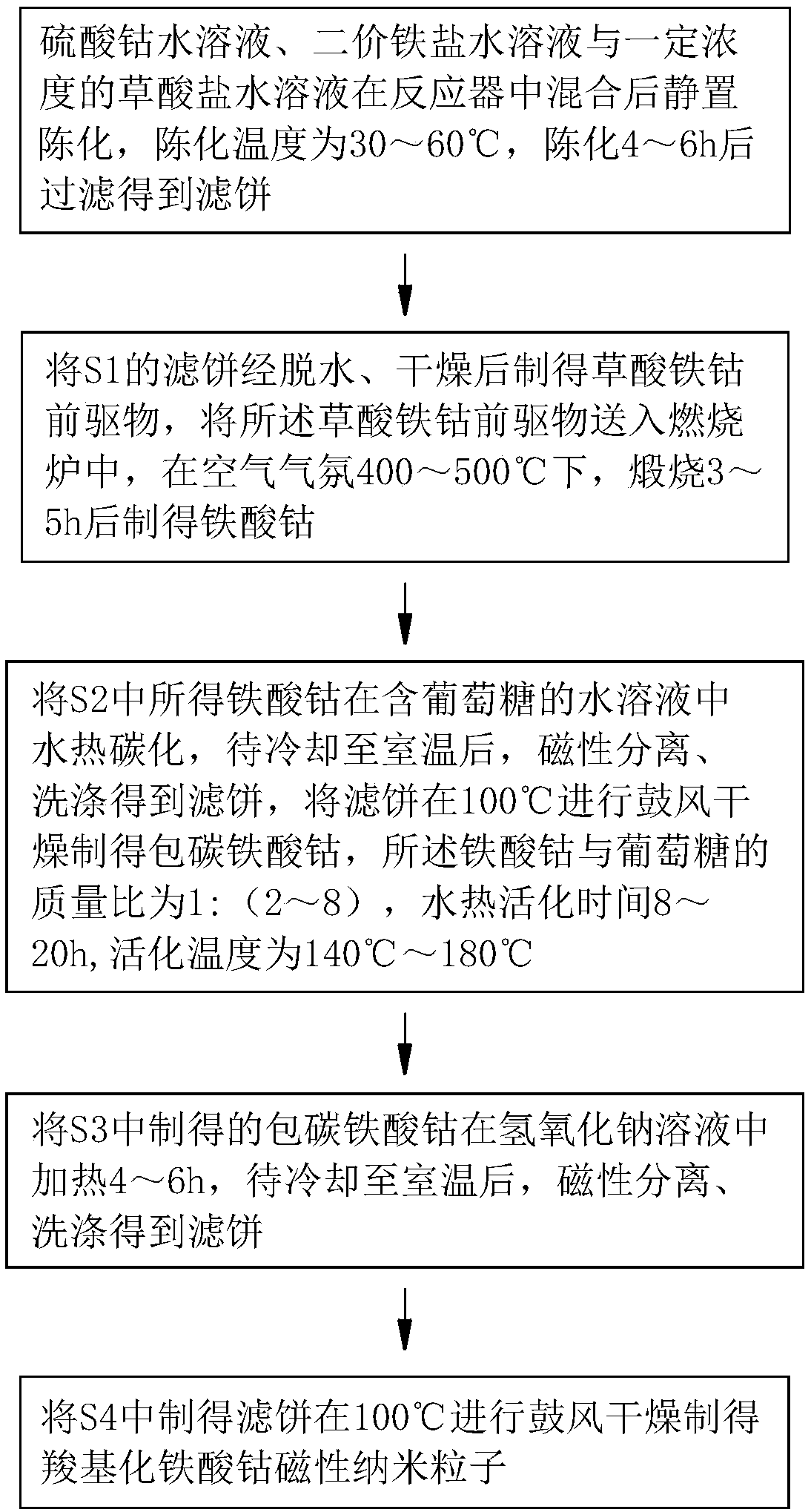

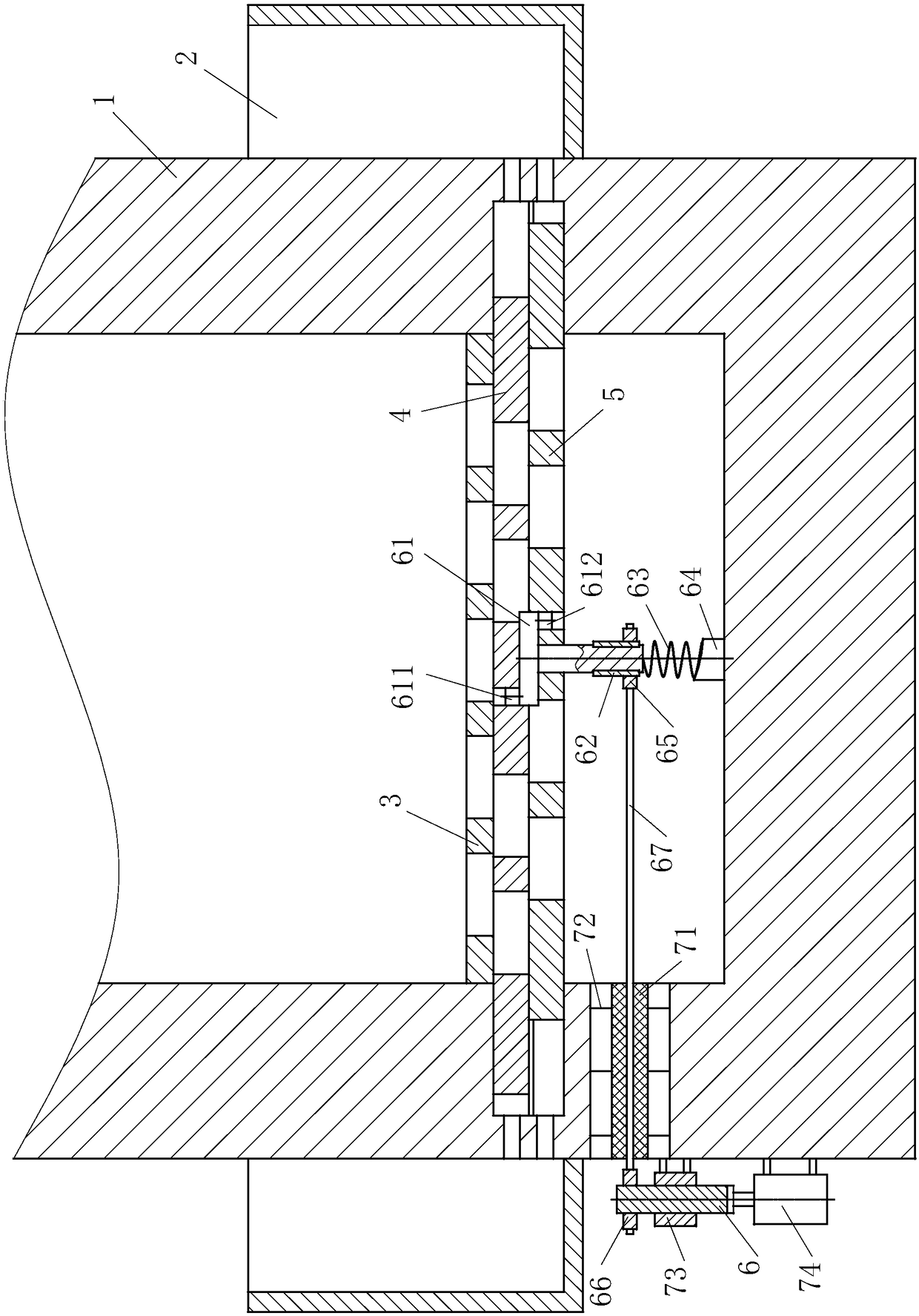

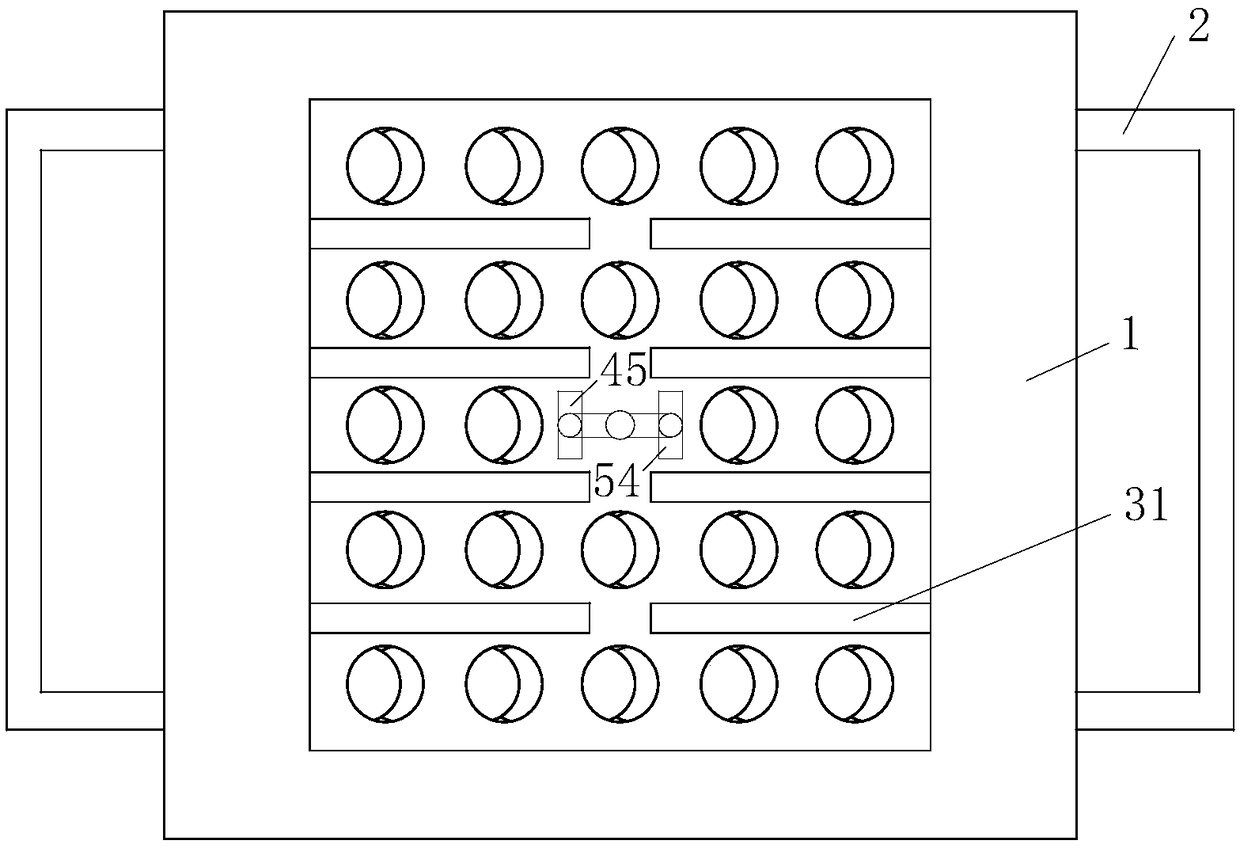

[0025] Such as Figure 1 to Figure 5 Shown, a kind of CoFe described in the present invention 2 o 4 A preparation method for nanoparticles, the preparation method comprising the steps of:

[0026] S1: Cobalt sulfate aqueous solution, ferrous salt aqueous solution and oxalate aqueous solution of a certain concentration are mixed in a reactor and then left to age at a temperature of 30-60°C. After aging for 4-6 hours, filter to obtain a filter cake;

[0027] S2: The iron-cobalt oxalate precursor is prepared by dehydrating and drying the filter cake of S1, and the iron-cobalt oxalate precursor is sent into a combustion furnace, and calcined for 3-5 hours in an air atmosphere at 400-500°C. cobalt ferrite;

[0028] S3: hydrothermally carbonize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com