Straw fertilizer biological fermenting liquid and preparation method thereof

A bio-fermentation and straw fertilizer technology, which is applied to fertilizer mixtures, organic fertilizers, and fertilizers made from biological waste, can solve the problems of single nutrient content, low cost performance, and slow fertilizer efficiency, and achieve rich nutrition, low cost, and benefit. absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

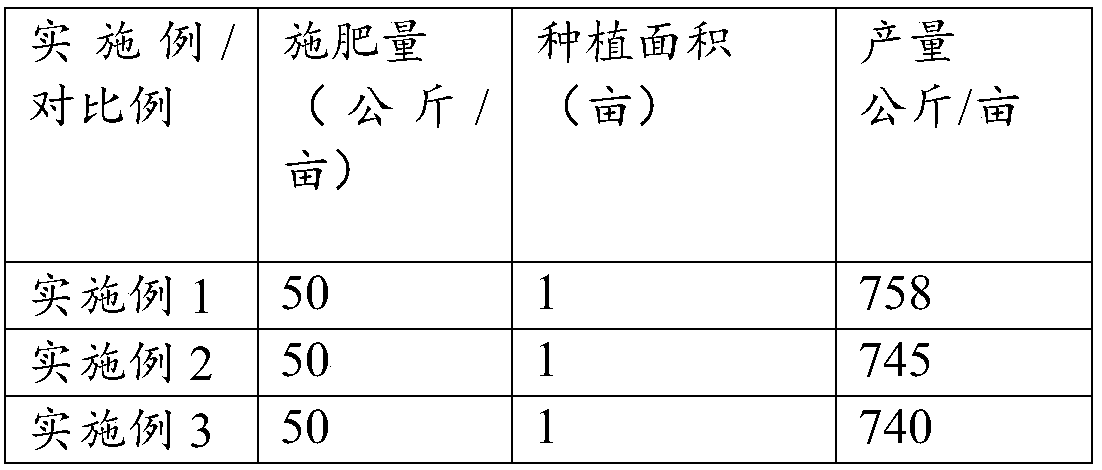

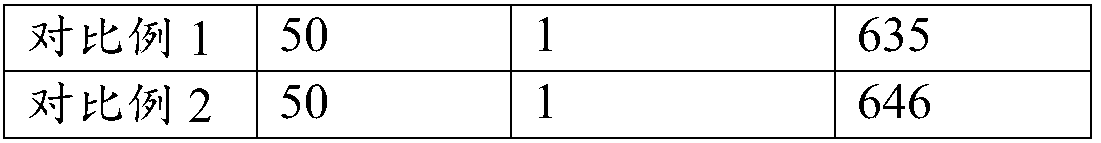

Examples

preparation example Construction

[0032] The present invention also relates to a preparation method of straw fertilizer biological fermentation liquid, comprising the following steps:

[0033] (1) Refining: After mixing plant stalks, pumpkins, potatoes, tomatoes, beet sugar residues, and soybeans with water, grind them to make a slurry.

[0034] In one embodiment of the present invention, the plant stalks are first cut into straw sections with a length of 2-5 cm, mixed with pumpkins, potatoes, tomatoes, beet sugar residues and soybeans, soaked in water for 5-10 hours, and then ground to make a slurry material.

[0035] In one embodiment of the present invention, during the grinding process, the slurry is sequentially passed through sieves of 60 mesh, 80 mesh, 100 mesh, and 120 mesh, and the size of the solids in the obtained slurry is ≥120 mesh.

[0036] (2) Sterilization: Sterilize the slurry at 110-120°C for 5-20 minutes to remove bacteria and spores therein.

[0037] (3) Fermentation: After cooling the st...

Embodiment 1

[0039] A straw fertilizer biological fermentation liquid, comprising the following raw material components in parts by weight:

[0040] 5 parts corn straw, 5 parts soybean straw, 5 parts wheat straw, 5 parts rice straw, 5 parts pumpkin, 5 parts potato, 5 parts tomato, 5 parts sugar beet residue, 2 parts soybean, 20 parts water, 1 part probiotic .

[0041] Among them, the probiotics include the following components in parts by weight: 15 parts of Candida lipolytica, 25 parts of Lactobacillus acidophilus, 15 parts of Lactobacillus bulgaricus, 10 parts of Streptococcus lactis, 5 parts of Paenibacillus nitrogen-fixing bacteria, and more 30 parts of Paenibacillus myxa.

[0042] The preparation method of the straw fertilizer biological fermentation liquid is as follows:

[0043] (1) Refining: Cut the plant straws into 2-5cm long straw sections, mix them with pumpkins, potatoes, tomatoes, beet sugar residues and soybeans, add water to soak for 5-10 hours, and pass through 60 mesh, ...

Embodiment 2

[0047] A straw fertilizer biological fermentation liquid, comprising the following raw material components in parts by weight:

[0048] 2.5 parts of corn straw, 2.5 parts of soybean straw, 2.5 parts of wheat straw, 2.5 parts of rice straw, 3 parts of pumpkin, 3 parts of potato, 3 parts of tomato, 3 parts of sugar beet residue, 1 part of soybean, 10 parts of water, 0.5 part of probiotics .

[0049] Among them, the probiotics include the following components in parts by weight: 10 parts of Candida lipolytica, 20 parts of Lactobacillus acidophilus, 10 parts of Lactobacillus bulgaricus, 5 parts of Streptococcus lactis, 3 parts of Paenibacillus nitrogen-fixing bacteria, and more 25 parts of Paenibacillus myxa.

[0050] The preparation process of the biological fermentation broth is the same as in Example 1.

[0051] Example 2

[0052] A straw fertilizer biological fermentation liquid, comprising the following raw material components in parts by weight:

[0053] 7 parts of corn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com