A method for efficiently preparing zif-8 materials

A ZIF-8, high-efficiency technology, applied in the field of efficient preparation of ZIF-8 materials, can solve the problems of increasing the preparation cost, increasing the complexity of the preparation process, and the cumbersome experimental operation, so as to achieve improved separation performance, controllable morphology, and improved The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

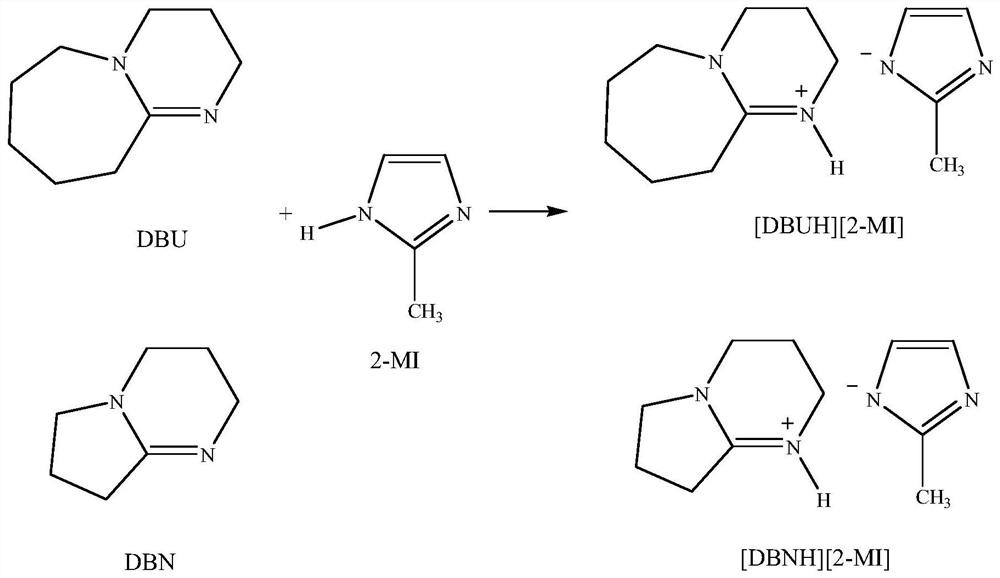

[0029] (1) Stir and mix zinc acetate, 2-methylimidazole, and distilled water at a molar ratio of 1:25:833 at room temperature to obtain a milky white solution;

[0030] (2) Add 1,8-diazabicyclo[5.4.0]undec-7-ene with a molar ratio of 2:25 to 2-methylimidazole in the milky white solution prepared in step (1), at room temperature Stir and mix evenly to obtain a milky white suspension;

[0031] (3) Transfer the milky white suspension prepared in step (2) to a polytetrafluoroethylene-lined hydrothermal synthesis reaction kettle, and then place the reaction kettle in an oven for hydrothermal reaction at 120°C for 0.5h , after the hydrothermal reaction, the reaction solution was left to cool and centrifuged to obtain a white solid, which was washed alternately with ethanol and distilled water 6 times each, and washed with distilled water for the last time, and then vacuum-dried at 100°C for 2 hours to obtain a white powder Solid, namely ZIF-8.

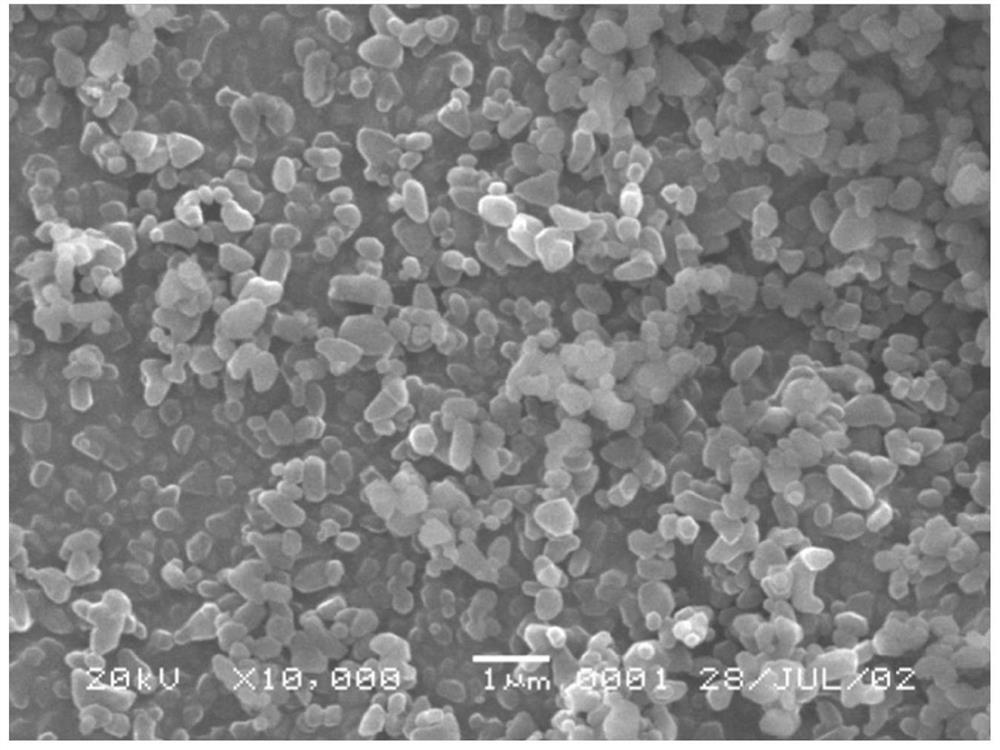

[0032] Depend on figure 2 It can ...

Embodiment 2

[0041] (1) Stir and mix zinc acetate, 2-methylimidazole, and distilled water at a molar ratio of 1:25:1111 at room temperature to obtain a milky white solution;

[0042] (2) Add 1,8-diazabicyclo[5.4.0]undec-7-ene with a molar ratio of 1:25 to 2-methylimidazole in the milky white solution prepared in step (1), at room temperature Stir and mix evenly to obtain a milky white suspension;

[0043] (3) Transfer the milky white suspension prepared in step (2) to a polytetrafluoroethylene-lined hydrothermal synthesis reaction kettle, and then place the reaction kettle in an oven for hydrothermal reaction at 120°C for 0.5h After the hydrothermal reaction, the reaction liquid was left to cool and centrifuged to obtain a white solid, which was washed alternately with ethanol and distilled water for 5 times each, and washed with distilled water for the last time, and then vacuum-dried at 90°C for 3 hours to obtain a white powder Solid, namely ZIF-8.

[0044] Depend on Figure 7 It can ...

Embodiment 3

[0047] (1) Stir and mix zinc acetate, 2-methylimidazole, and distilled water at a molar ratio of 1:25:500 at room temperature to obtain a milky white solution;

[0048] (2) Add 1,8-diazabicyclo[5.4.0]undec-7-ene with a molar ratio of 3:25 to 2-methylimidazole in the milky white solution prepared in step (1), at room temperature Stir and mix evenly to obtain a milky white suspension;

[0049] (3) Transfer the milky white suspension prepared in step (2) to a polytetrafluoroethylene-lined hydrothermal synthesis reaction kettle, and then place the reaction kettle in an oven for hydrothermal reaction at 120°C for 0.5h , after the hydrothermal reaction, the reaction solution was left to cool and centrifuged to obtain a white solid, which was washed alternately with ethanol and distilled water 6 times each, and washed with distilled water for the last time, and then vacuum-dried at 100°C for 2 hours to obtain a white powder Solid, namely ZIF-8.

[0050] Depend on Figure 8 It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com