Silicon rubber base, double-component silicon rubber and preparation methods of silicon rubber base and double-component silicon rubber

A silicone rubber and two-component technology, applied in the chemical industry, can solve the problems of high preparation cost, low production efficiency, and many amine impurities, and achieve improved viscosity and thickening, excellent tensile strength, and good tear strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

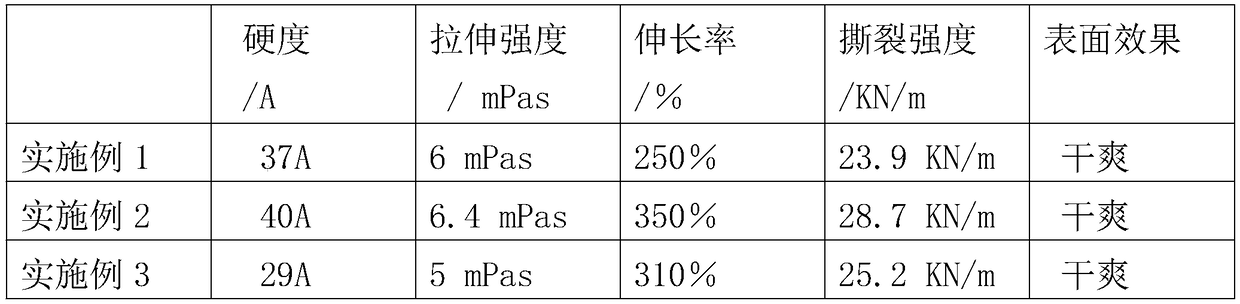

Examples

Embodiment 1

[0048] Silicone rubber base glue raw material formula comprises each component of following parts by weight:

[0049] Vinyl silicone oil 100 parts

[0050] White carbon black 40 parts

[0051] 15 parts of dimethylsilazane;

[0052] Wherein, the vinyl silicone oil is dimethylvinyl-terminated polydimethylsiloxane with a viscosity of 500-3000cp, and the white carbon black is precipitated white carbon black.

[0053] Preparation:

[0054] Include the following steps:

[0055] Step 1, pretreatment of white carbon black, add 40 parts of white carbon black and 15 parts of dimethylsilazane to the mixing bucket at the same time, cover and seal, mix at room temperature for 10-30 minutes, and park at room temperature for 12 hours Open the sealing cover for standby. In this step, the white carbon black powder has been pretreated to ensure that the white carbon black powder and dimethylsilazane can fully react, so that the white carbon black powder changes from hydrophilic to The lipo...

Embodiment 2

[0080] Silicone rubber base glue raw material formula comprises each component of following parts by weight

[0081] Vinyl silicone oil 100 parts

[0082] White carbon black 50 parts

[0083] 30 parts of dimethylsilazane;

[0084] Wherein, the vinyl silicone oil is dimethylvinylsiloxy-terminated polydimethylsiloxane, and its viscosity is 500-3000cp.

[0085] Preparation method: with embodiment 1.

[0086] This embodiment also provides a two-component silicone rubber, the silicone rubber includes two components A and B, and the A component and the B component both contain the Silicone rubber base glue, said component A comprises the following components by weight:

[0087] Silicone rubber base 100 parts

[0088] Vinyl silicone oil 8.5 parts

[0089] Platinum complex 0.2 parts

[0090] The viscosity of the vinyl silicone oil is 500-1000CP;

[0091] The B component comprises the following components by weight:

[0092] Silicone rubber base 100 parts

[0093] Hydrogen si...

Embodiment 3

[0099] Silicone rubber base glue raw material formula comprises each component of following parts by weight

[0100] Vinyl silicone oil 100 parts

[0101] White carbon black 60 parts

[0102] 40 parts of dimethylsilazane;

[0103] Wherein, the vinyl silicone oil is dimethylvinyl-terminated polydimethylsiloxane, and its viscosity is

[0104] 500-3000cp.

[0105] Preparation method: with embodiment 1.

[0106] This embodiment also provides a two-component silicone rubber, the silicone rubber includes two components A and B, and the A component and the B component both contain the Silicone rubber base glue, said component A comprises the following components by weight:

[0107] Silicone rubber base 100 parts

[0108] Vinyl silicone oil 10 parts

[0109] Platinum complex 0.3 parts

[0110] The viscosity of the vinyl silicone oil is 500-1000CP;

[0111] The B component comprises the following components by weight:

[0112] Silicone rubber base 100 parts

[0113] Hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com