Cast tin bronze for friction pair of aviation hydraulic pump and its melting method

A tin bronze and hydraulic pump technology, which is applied in the field of casting tin bronze for the friction pair of aviation hydraulic pumps and its smelting, can solve the problems of large expansion coefficient of tin bronze, poor bearing capacity of tin bronze, poor bearing capacity and wear resistance of tin bronze, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

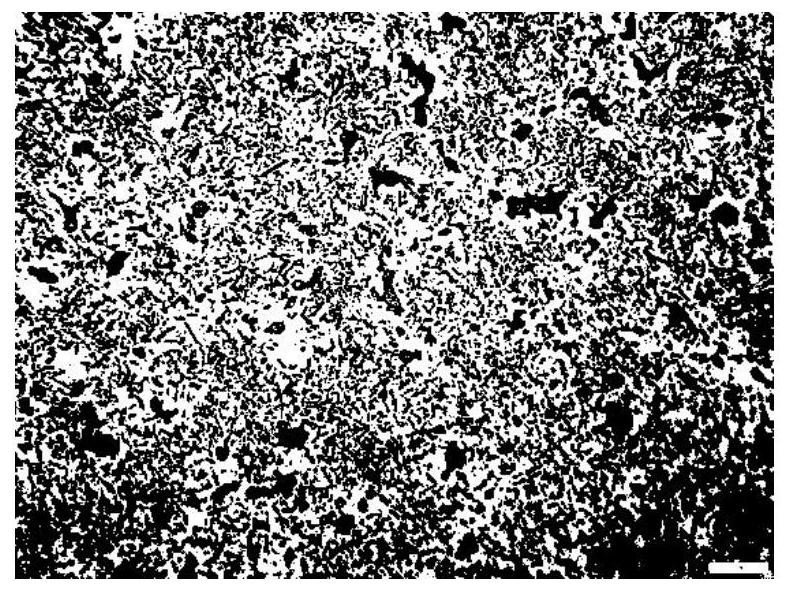

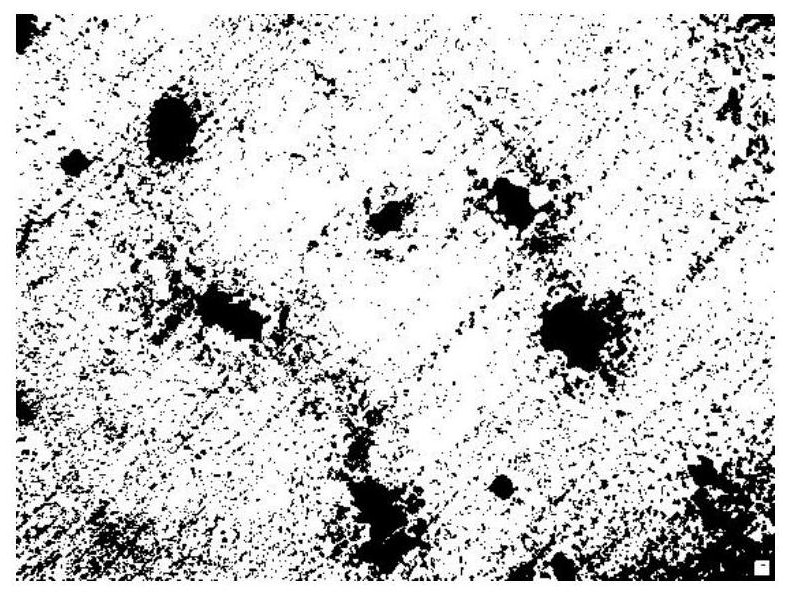

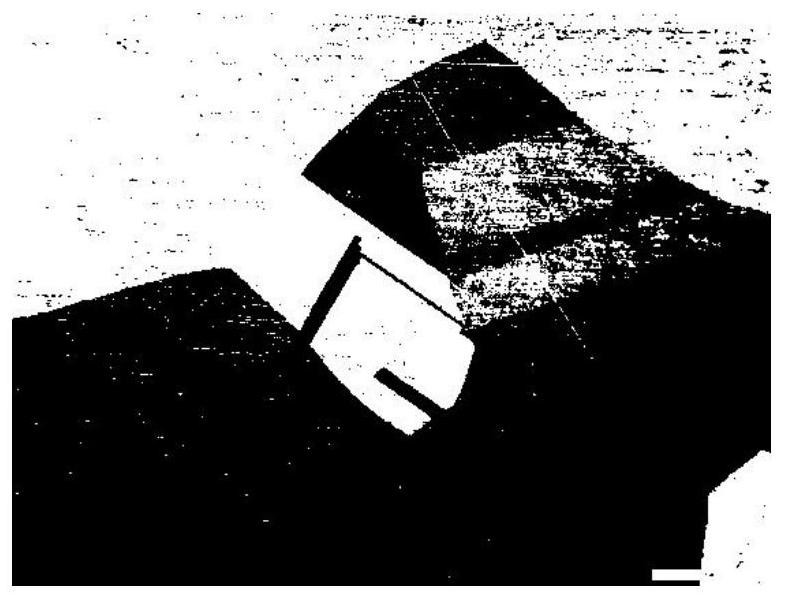

Image

Examples

Embodiment 1

[0026] Example 1. A cast tin bronze for the friction pair of an aviation hydraulic pump, comprising 9-11% tin, 6-8% nickel, 2-3.3% lead, 0.2-0.5% zinc, and 0.1% oxidized rare earth CeO 2 , 0.01 to 0.1% phosphorus, and the rest is copper.

[0027] The smelting method of casting tin bronze for the friction pair of aviation hydraulic pumps first prepares the raw materials for making tin bronze, including 6Kg of pure tin, 1.5Kg of pure lead, 24.77Kg of copper-nickel alloy (containing 4.8Kg of nickel, and the rest is copper), 0.3Kg of pure zinc, 0.06kg of rare earth oxide, 0.4kg of phosphorus copper (containing 0.06kg of phosphorus, the rest is copper), 26.97Kg of pure copper, and a total of 60Kg of raw materials. Then use 50 / 100 grain size quartz sand mixed with 5-8% rapeseed oil to make the sand riser and rain block, and heat the sand riser and rain block to 200-400°C and keep it warm for 1.5-2.5 h; Then clean the sand cover riser and rain block, repair the small head of the r...

Embodiment 2

[0035] Example 2. A cast tin bronze for the friction pair of an aviation hydraulic pump, comprising 9-11% tin, 6-8% nickel, 2-3.3% lead, 0.2-0.5% zinc, and 0.1% oxidized rare earth CeO 2 , 0.01 to 0.1% phosphorus, and the rest is copper.

[0036]The smelting method of casting tin bronze for the friction pair of aviation hydraulic pump, first prepare the raw materials for making tin bronze, including 5.4Kg of pure tin, 1.5Kg of pure lead, 22.12Kg of copper-nickel alloy (4.2Kg of nickel, the rest is copper) , 0.3Kg of pure zinc, 0.06kg of rare earth oxide, 0.4kg of phosphorus copper (containing 0.06kg of phosphorus, the rest is copper), 30.22Kg of pure copper, and a total of 60Kg of raw materials. Then use 50 / 100 grain size quartz sand mixed with 5-8% rapeseed oil to make the sand riser and rain block, and heat the sand riser and rain block to 200-400°C and keep it warm for 1.5-2.5 h; Then clean the sand cover riser and rain block, repair the small head of the rain hole to Ф6...

Embodiment 3

[0044] Example 3. A cast tin bronze for the friction pair of an aviation hydraulic pump, comprising 9-11% tin, 6-8% nickel, 2-3.3% lead, 0.2-0.5% zinc, and 0.1% oxidized rare earth CeO 2 , 0.01 to 0.1% phosphorus, and the rest is copper.

[0045] The smelting method of casting tin bronze for the friction pair of aviation hydraulic pumps first prepares the raw materials for making tin bronze, including 5.6Kg of pure tin, 1.35Kg of pure lead, and 19.89Kg of copper-nickel alloy (containing 3.78Kg of nickel, and the rest is copper) , 0.3Kg of pure zinc, 0.06kg of rare earth oxide, 0.4kg of phosphorus copper (containing 0.06kg of phosphorus, the rest is copper), 32.4Kg of pure copper, and a total of 60Kg of raw materials. Then use 50 / 100 grain size quartz sand mixed with 5-8% rapeseed oil to make the sand riser and rain block, and heat the sand riser and rain block to 200-400°C and keep it warm for 1.5-2.5 h; Then clean the sand cover riser and rain block, repair the small head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com