A kind of novel nickel phosphide catalyst and preparation method thereof

A catalyst, nickel phosphide technology, applied in electrolytic components, electrodes, electrolytic process, etc., to achieve low cost, broad application prospects, and excellent catalytic reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a nickel phosphide catalyst with nitrogen and phosphorus co-doped porous carbon coated catalyst centers evenly distributed, the steps are as follows:

[0048] 1) Preparation of MOFs precursors containing nitrogen and phosphorus atoms:

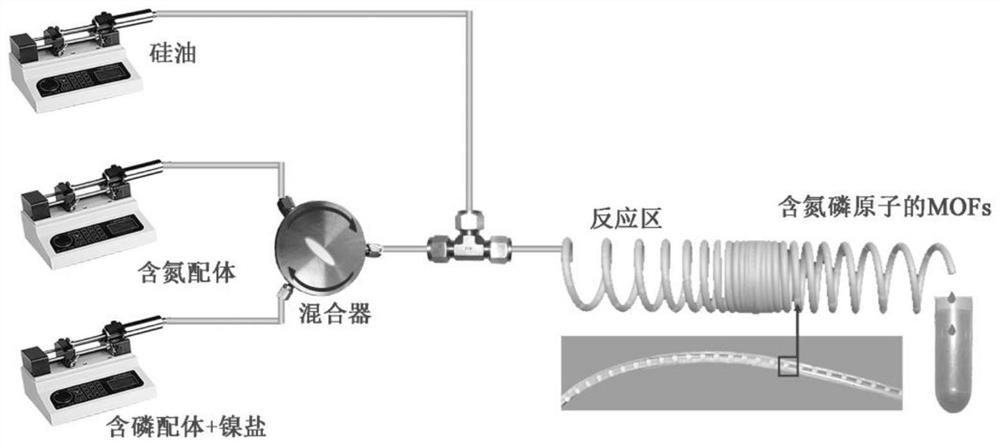

[0049] Disperse nickel sulfate, 2,4,6-trimethylbenzene-1,3,5-trimethylenetriphosphonic acid ligand and 4,4'-bipyridyl into deionized water, and configure the concentration to be 0.15 molar per liter, 0.1 molar per liter and 0.15 molar per liter solutions, and use the attached figure 1 The device puts the raw materials into the mixer and enters the reaction zone. The temperature of the reaction zone is 100°C, and the residence time is 80 minutes. The product is collected at the nozzle at the end, centrifuged or filtered to separate the product, and the nitrogen-containing phosphorus can be obtained. Atomic MOFs precursors.

[0050] 2) Weigh 0.5 g of the MOFs precursor containing nitrogen and phosphorus atoms in st...

Embodiment 2

[0056] A method for preparing a nickel phosphide catalyst with nitrogen and phosphorus co-doped porous carbon coated catalyst centers evenly distributed, the steps are as follows:

[0057] 1) Preparation of MOFs precursors containing nitrogen and phosphorus atoms:

[0058] Disperse nickel sulfate, 2,4,6-trimethylbenzene-1,3-dimethylene diphosphonic acid ligand and 4,4'-bipyridine into deionized water, and configure the concentrations to be 0.15 moles per liter, 0.1 mole per liter and 0.15 mole per liter solution, and use the attached figure 1 The device puts the raw materials into the mixer and enters the reaction zone. The temperature of the reaction zone is 100°C, and the residence time is 80 minutes. The product is collected at the nozzle at the end, centrifuged or filtered to separate the product, and the nitrogen-containing phosphorus can be obtained. Atomic MOFs precursors.

[0059] 2) Weigh 0.5 g of the MOFs precursor containing nitrogen and phosphorus atoms in step 1...

Embodiment 3

[0061] A method for preparing a nickel phosphide catalyst with nitrogen and phosphorus co-doped porous carbon coated catalyst centers evenly distributed, the steps are as follows:

[0062] 1) Preparation of MOFs precursors containing nitrogen and phosphorus atoms:

[0063] Disperse nickel sulfate, 2,4,6-trimethylbenzene-1,3,5-trimethylenetriphosphonic acid ligand and 4,4'-bipyridyl into deionized water, and configure the concentration to be 0.15 molar per liter, 0.2 molar per liter and 0.15 molar per liter solutions, and use the attached figure 1 The device puts the raw materials into the mixer and enters the reaction zone. The temperature of the reaction zone is 100°C, and the residence time is 80 minutes. The product is collected at the nozzle at the end, centrifuged or filtered to separate the product, and the nitrogen-containing phosphorus can be obtained. Atomic MOFs precursors.

[0064] 2) Weigh 0.5 g of the MOFs precursor containing nitrogen and phosphorus atoms in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com