Airtight external thermal type rotary furnace with same-side feed and discharge functions

An external heating rotary furnace and feeding technology, which is applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the equipment specification and manufacturing difficulty of increasing the heat-carrying gas processing capacity, the equipment processing capacity should not be too large, and it is not suitable for difficult processing. materials and other problems, to achieve the effect of reducing energy consumption, simple and convenient maintenance, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

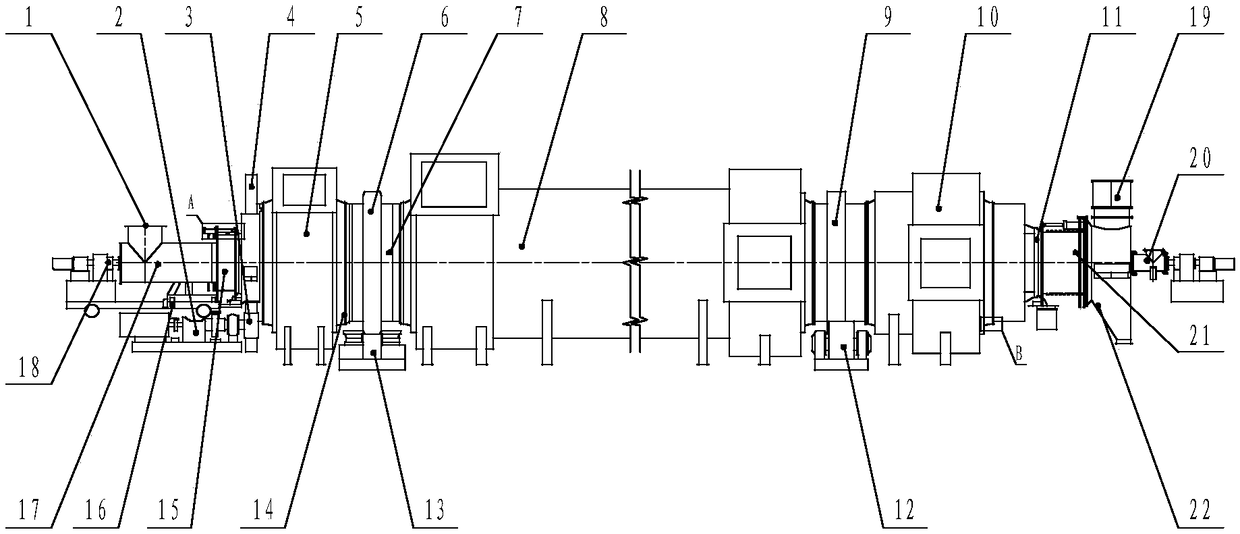

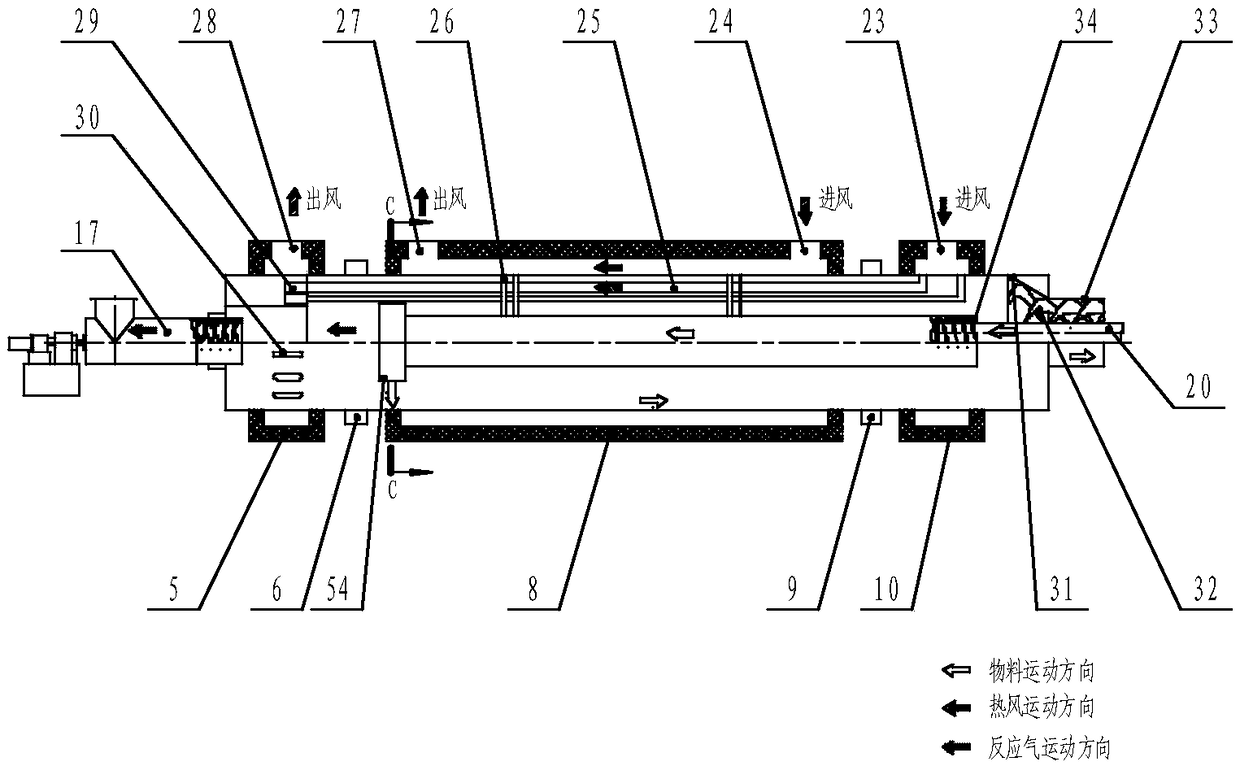

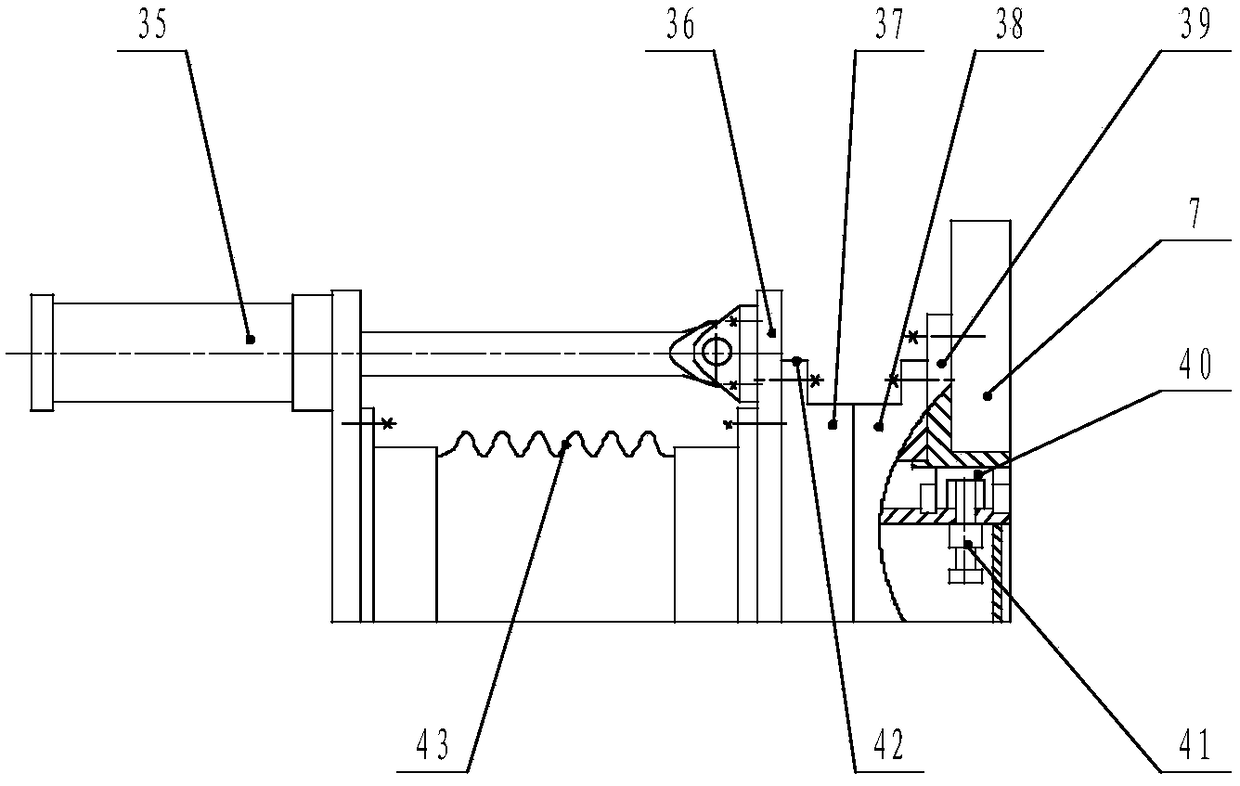

[0037] as attached figure 1 As shown, the closed externally heated rotary furnace on the same side of the inlet and outlet includes the furnace body 7 formed by the airtight furnace wall and the indirect heating of the tube wall. The supporting roller device 12 supporting the furnace body 7 is arranged between the jackets; the inner chamber of the furnace body 7 is provided with a tube bundle 25 distributed along the axial direction of the furnace body. The air jacket and the tube bundle 25 form an independent heat-carrying gas channel inside the furnace body, and the intermediate jacket and the outer wall of the furnace body 7 form an independent heat-carrying gas channel outside the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com