Device and method for removing impurities and oil of ammonium bicarbonate solution

An ammonium bicarbonate and solution technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high labor intensity, high labor cost, poor operating environment, etc., and reduce the cost of consumables and labor. Optimize process equipment and processes to achieve the effect of automated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

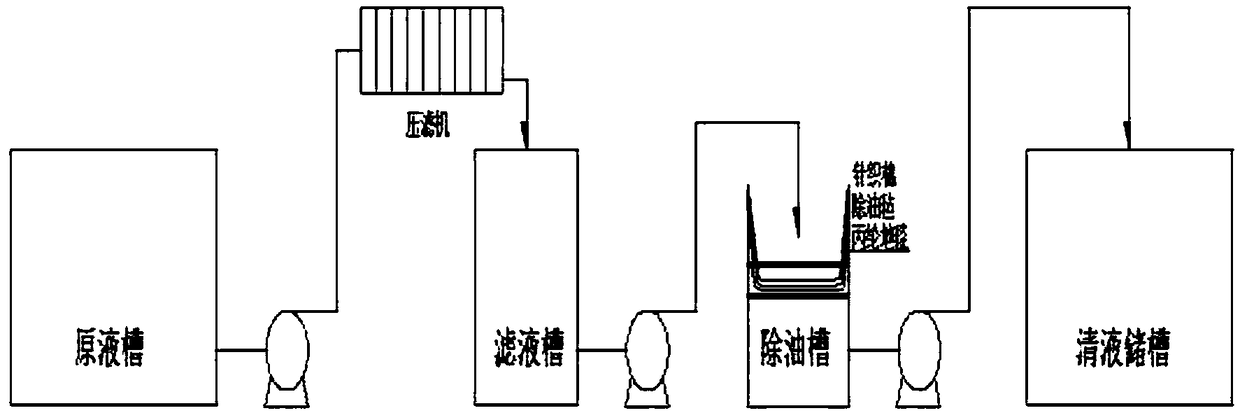

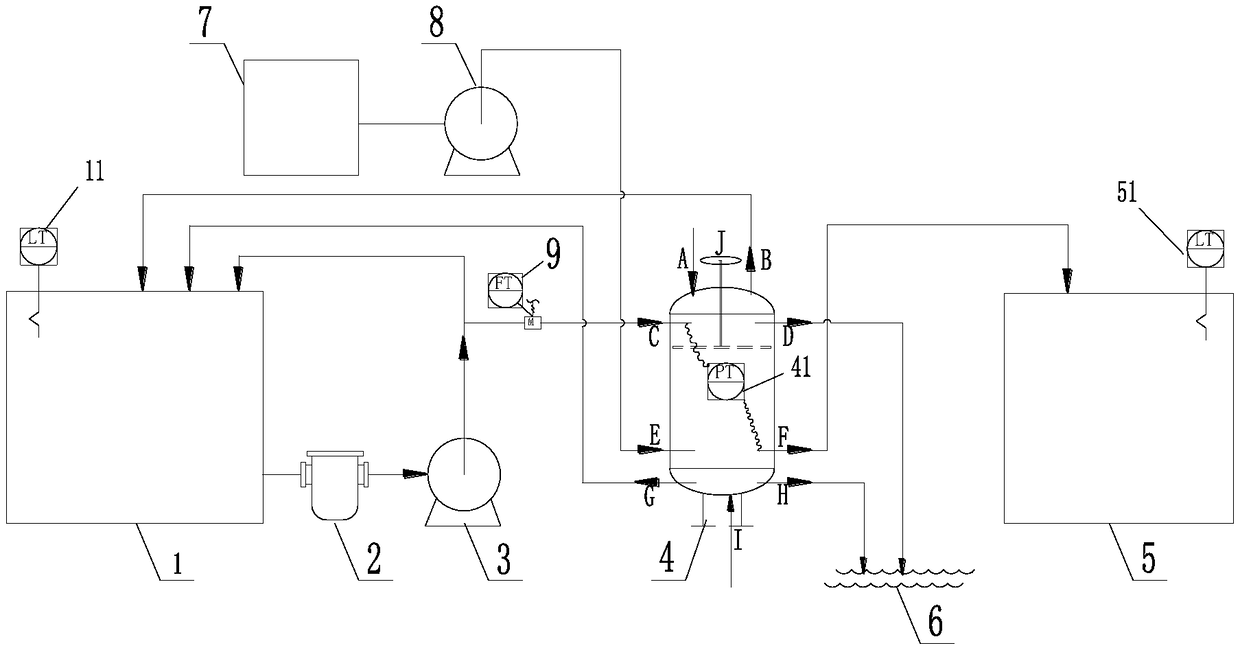

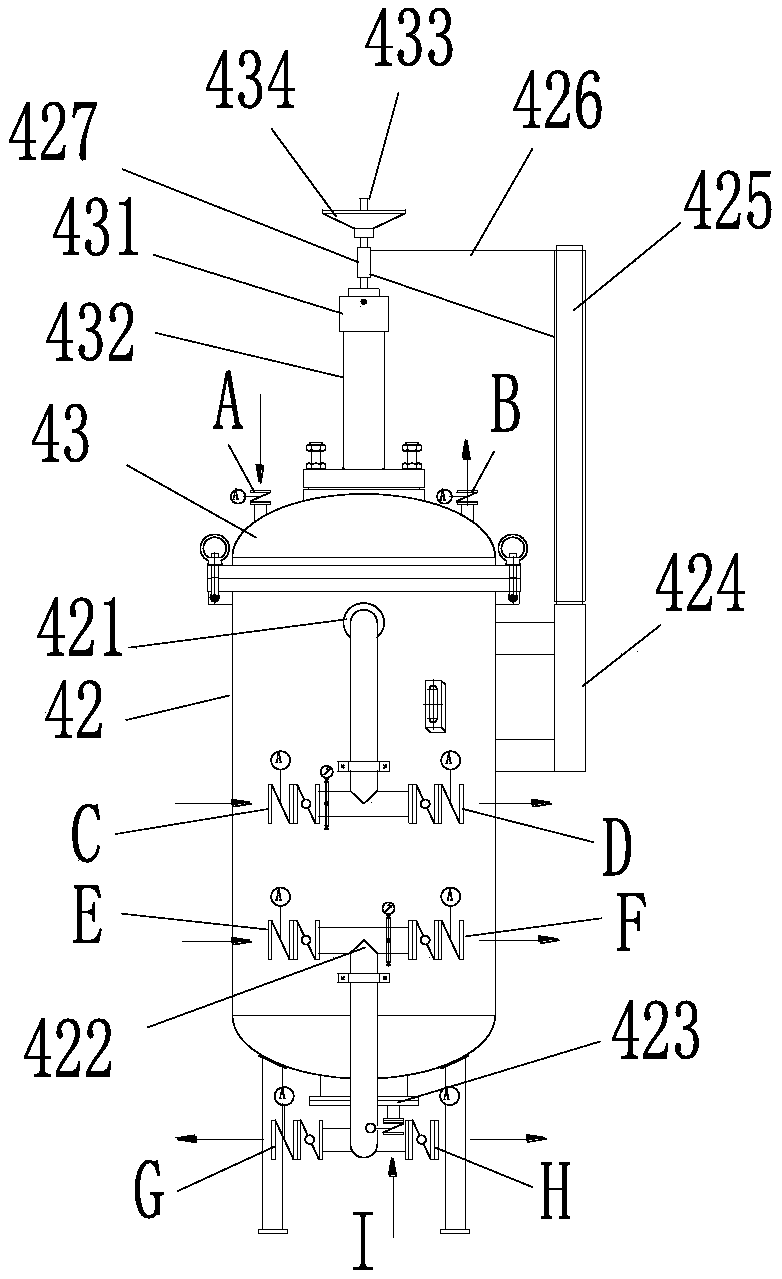

[0036] Such as figure 2 Shown is the structural representation of the device for removing impurities and oil from ammonium bicarbonate solution in the present invention.

[0037] The structure of the device for removing impurities and oil from ammonia bicarbonate solution includes: stock solution tank 1, basket filter 2, stock solution pump 3, fiber ball filter 4, clear liquid tank 5, production waste water flow tank 6, backwash water storage tank 7. Backwash water pump8.

[0038] Raw solution tank 1, raw solution pump 3, fiber ball filter 4, and clear liquid tank 5 are connected sequentially through pipelines, basket filter 2 is arranged on the pipeline between raw solution tank 1 and raw solution pump 3, and electromagnetic flowmeter 9 is set On the pipeline between the stock solution pump 3 and the fiber ball f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com