Vertical milling sand making machine

A sand machine and grinding technology, applied in grain processing, etc., can solve the problems of high energy consumption per unit of finished sand, short life of wearing parts, low equipment operation rate, etc., and achieve small footprint and low consumption of wear-resistant materials , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

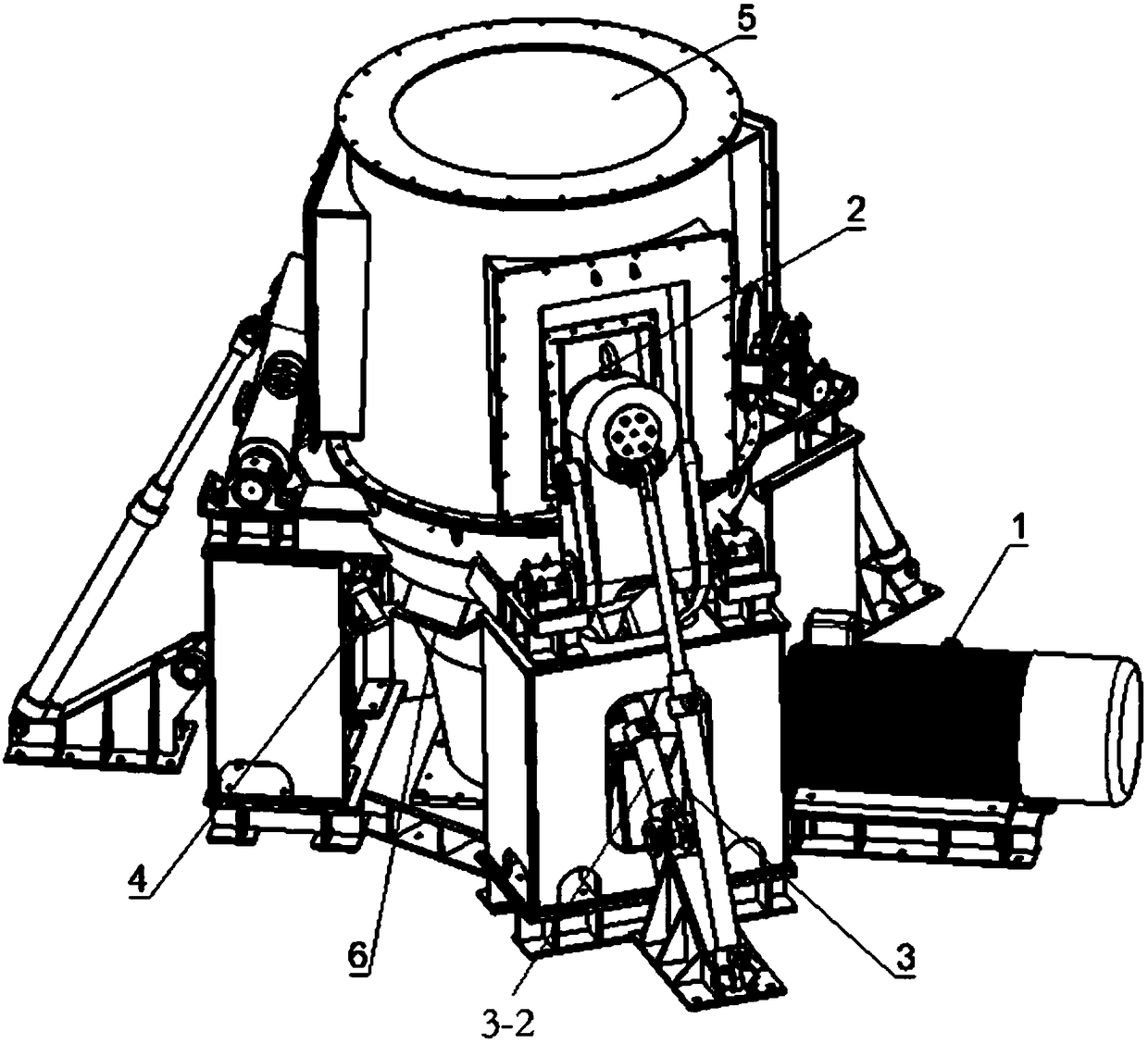

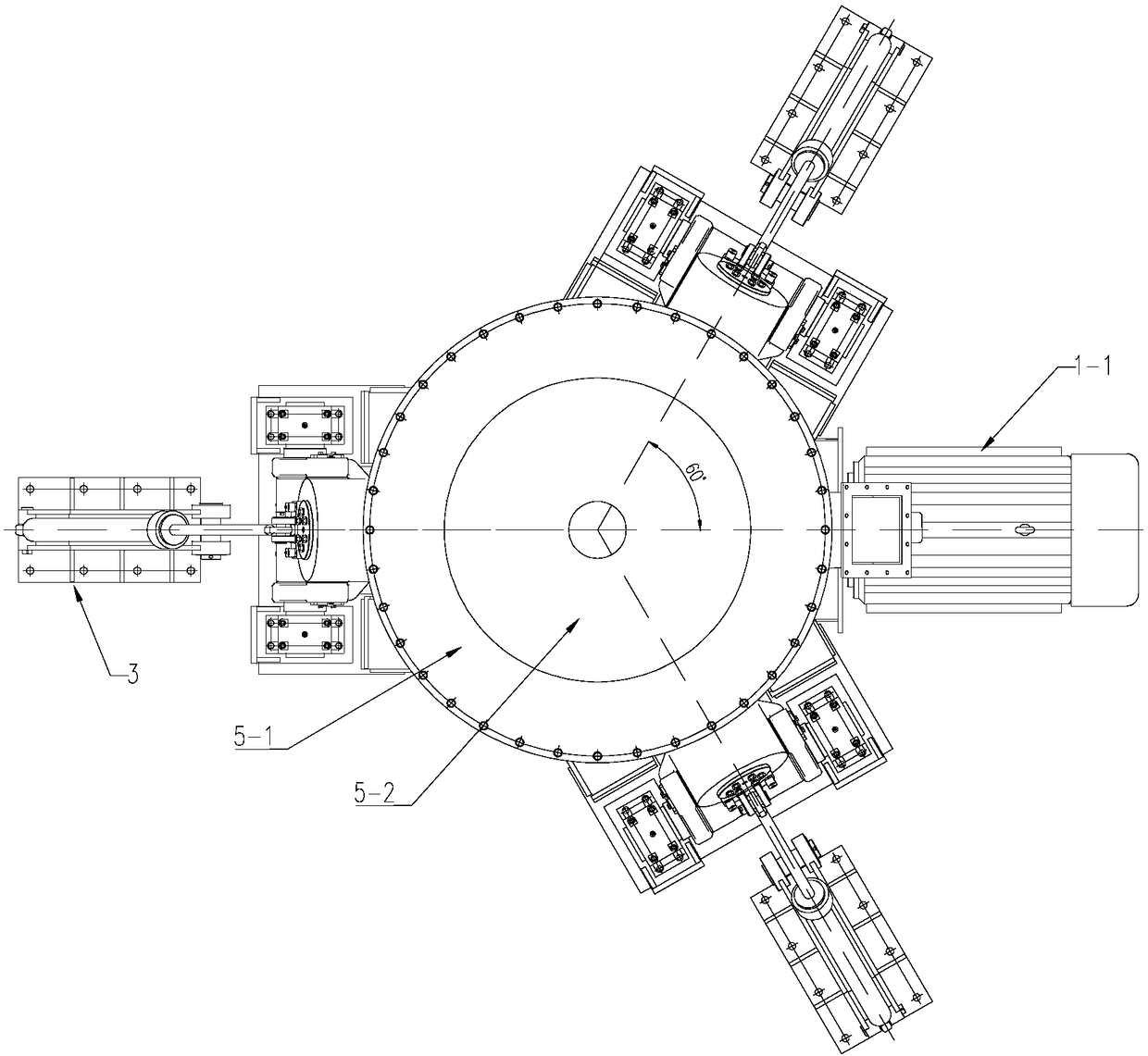

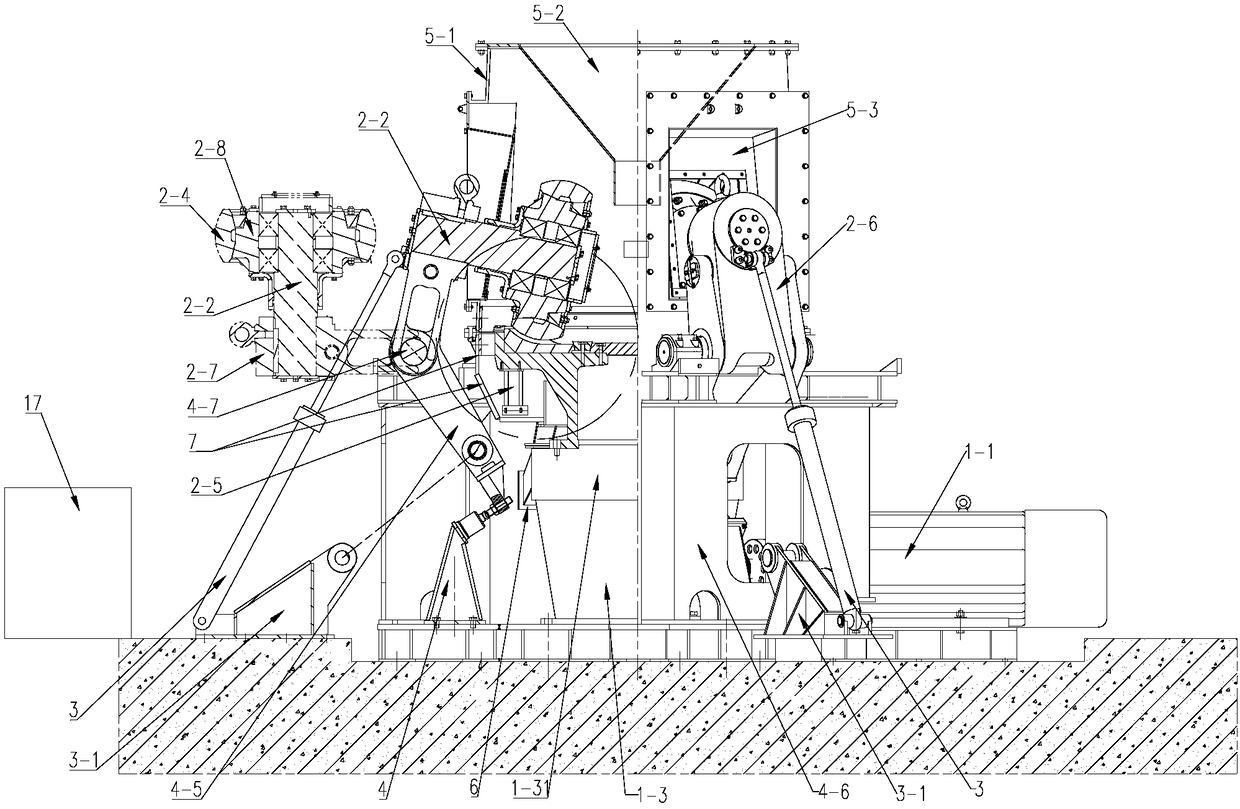

[0037] see Figure 1-10 , a vertical mill sand making machine, characterized in that:

[0038] Including transmission device 1, milling device 2, pressurizing device 3, limit device 4, feeding device 5, lower shell 7, unloading device 6;

[0039] The transmission device 1 includes a motor 1-1, a shaft coupling 1-2, and a speed reducer 1-3; the horizontal input shaft hole of the speed reducer 1-3 adopts a shaft coupling 1-2 to connect the motor 1 -1 output shaft; the vertical output shaft of the reducer 1-1 is connected to a turntable 1-31; the transmission device is provided with a lubricating system in this example, and the lubricating system adopts an oil station 17 for oil supply, and the lubricating The system is equipped with an oil pressure automatic protection system;

[0040] The feeding device 5 includes a crushing cylinder 5-1, a feed hopper 5-2 resting on the top of the crushing cylinder 5-1, and a wall between the feed hopper 5-2 and the crushing cylinder 5-1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com