A kind of antimony germanate glass and preparation method thereof

A technology of antimony germanate and glass, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc. It can solve the problems of small formation area and poor thermal stability, and achieve good glass forming performance, large refractive index, and phonon small energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

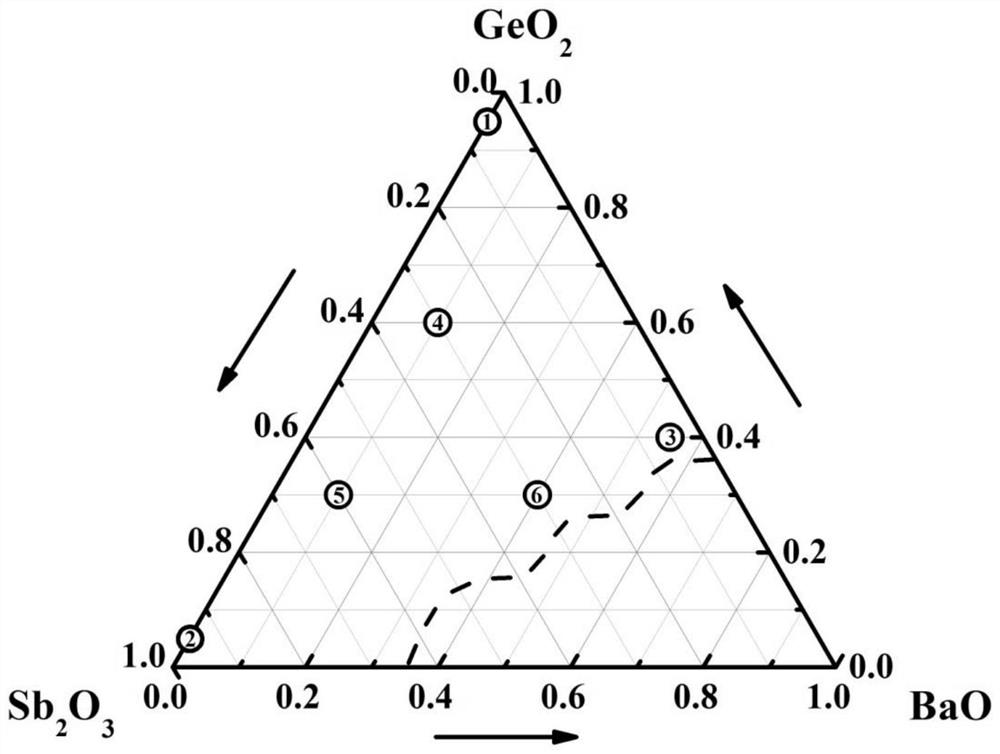

[0023] The embodiments of the present invention will be further described below in conjunction with specific examples and drawings, but the embodiments of the present invention are not limited thereto.

[0024] Table 1 provides the formulations of 6 specific examples of the present invention.

[0025] Table 1

[0026] Glass composition (mol%) Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 GeO 2

95 5 40 60 30 30 Sb 2 o 3

5 95 5 30 60 30 BaO 0 0 55 10 10 40

[0027] The preparation steps of germanium antimonate glass in embodiment 1~6 are as follows:

[0028] (1) Accurately weigh 20 g of raw materials according to the composition and proportion (BaO is BaCO 3 Introduced in the form of), the raw materials are all high-purity raw materials;

[0029] (2) Fully mix and grind the raw materials obtained in step (1) in an agate mortar, and the grinding time is 20 minutes;

[0030] (3) Transfer the uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com