Preparation method of BN/Cu composite material with low friction coefficient

A low friction coefficient, composite material technology, applied in the field of preparation of BN/Cu composite materials with low friction coefficient, to achieve good wear resistance, improve friction and wear performance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

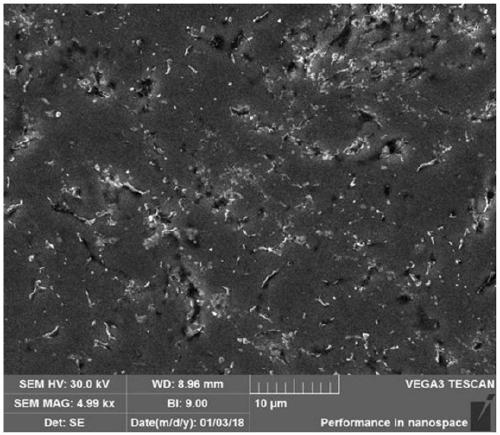

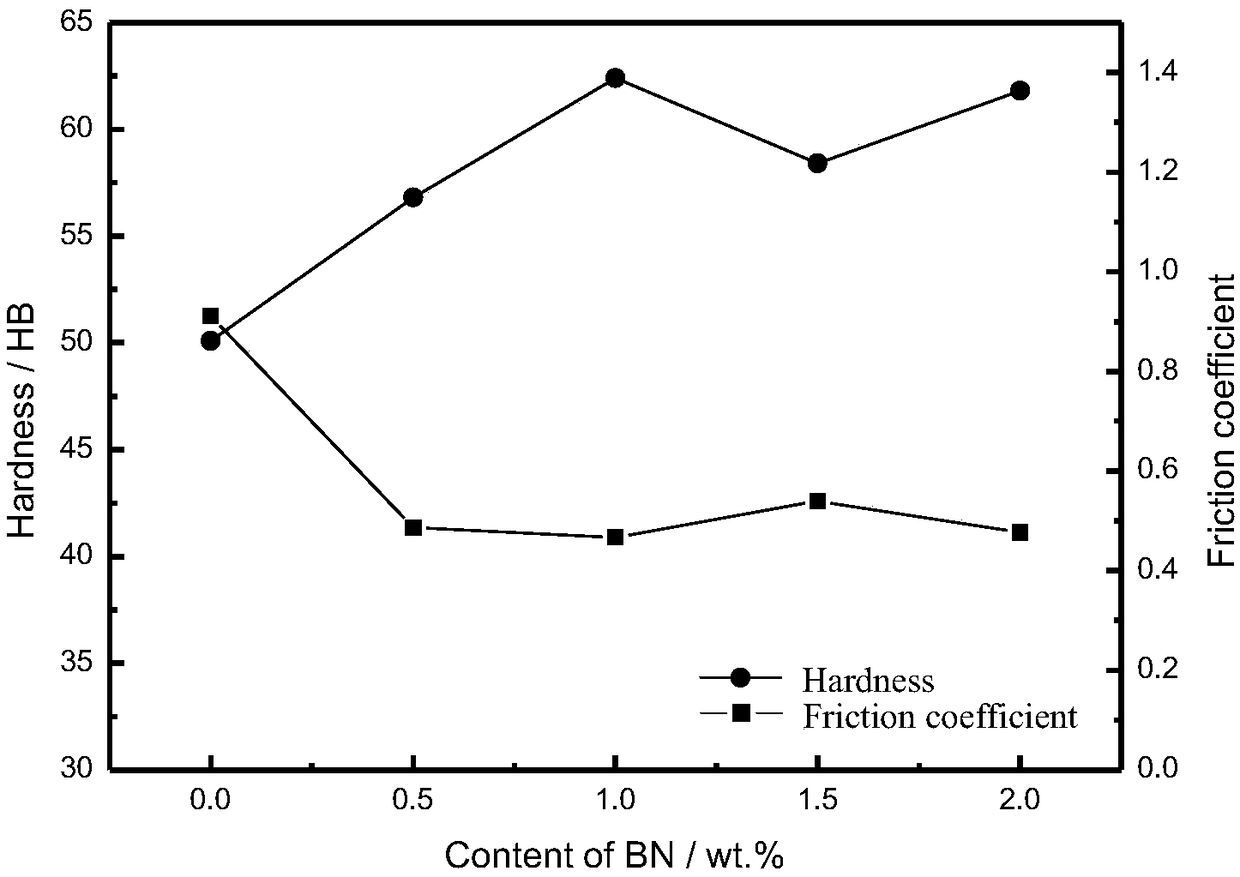

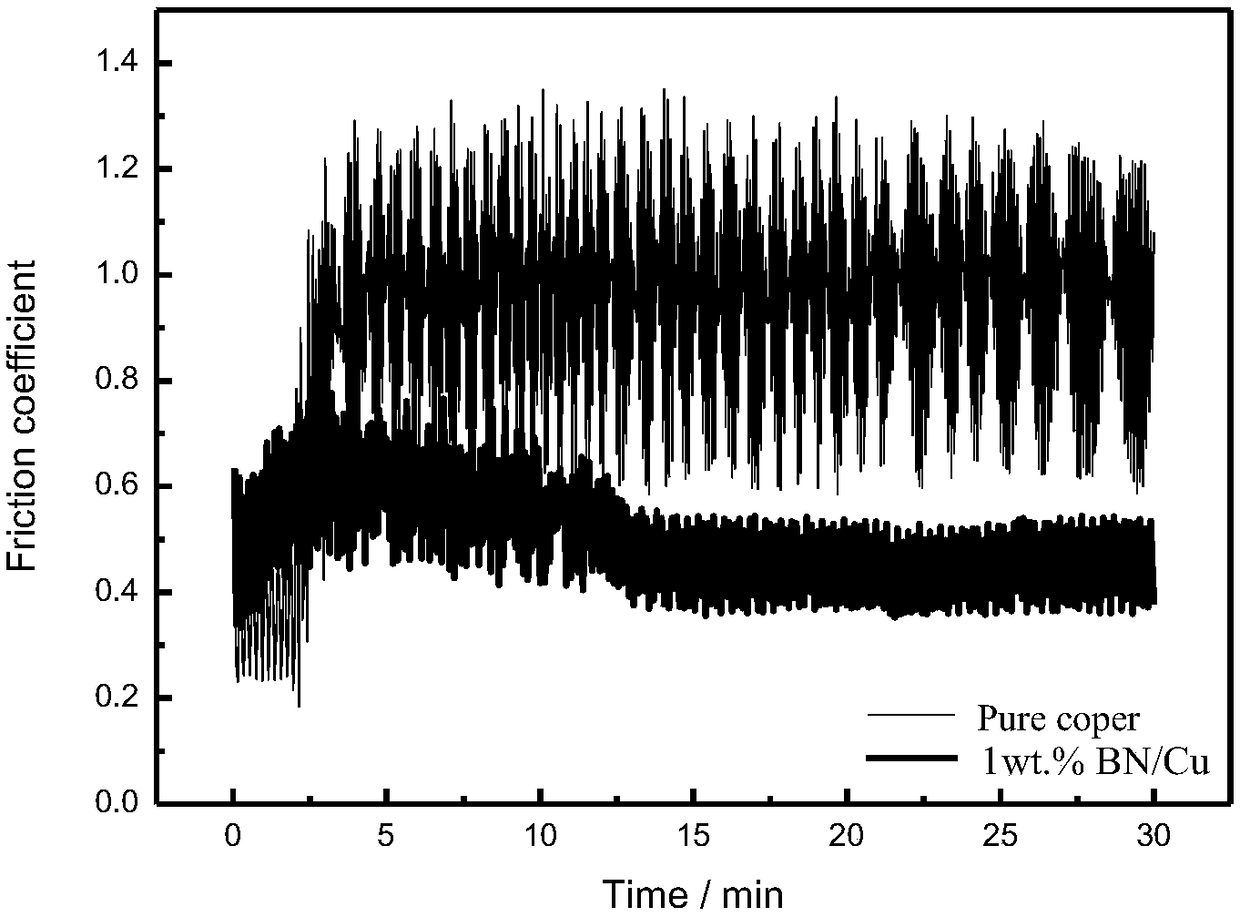

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method with low friction coefficient BN / Cu composite material, specifically comprises the following steps:

[0022] Step 1, mechanically mixing copper powder and boron nitride powder according to a certain ratio to obtain mixed powder;

[0023] Step 2, cold pressing the mixed powder in step 1 into a billet;

[0024] Step 3, hot-pressing and sintering the billet formed by cold pressing, and then cooling down with the furnace to obtain a BN / Cu composite material.

[0025] Wherein, in step 1, the boron nitride powder and copper powder are loaded into the mixer according to a certain ratio, wherein the boron nitride powder accounts for 0.5-2% of the total mass of the BN / Cu composite material, and then the copper powder and the nitrided 1:1 of the total mass of the boron powder was added to stainless steel grinding balls, and 1% of the total mass of the powder was added to the mixer as an anhydrous ethanol as a binder, and the po...

Embodiment 1

[0034] Weigh 1.5wt.% of nano-scale boron nitride powder, the balance is copper powder (40-60μm), put it into a mixer, and then add stainless steel grinding balls according to the total mass of copper powder and boron nitride powder at 1:1 , and add 1% of the total mass of powder to the mixer as an anhydrous ethanol as a binder, and mix the powder for 4 hours at a speed of 120r / min to obtain a mixed powder; the mixed powder is cold-pressed into a billet with a cold-pressing mold, and the cold-pressed During the process, the pressure is 300MPa, and the holding time is 30s, and the billet is cold-pressed into a billet; the billet formed by cold pressing is put into a Φ21 graphite crucible, and then put together into an atmosphere-protected hot-press furnace, and the temperature is raised from room temperature to 900 °C at 20 °C / min. ℃, hold for 30min, then heat at 10°C / min to 1040°C, hold for 50min, pressurize 21MPa, and finally cool to room temperature with the furnace to prepare...

Embodiment 2

[0036] Weigh 0.5wt.% of nano-scale boron nitride powder, the balance is copper powder (40-60μm), put it into a mixer, and then add stainless steel grinding balls according to the total mass of copper powder and boron nitride powder at 1:1 , and add 1% of the total mass of powder to the mixer as an anhydrous ethanol as a binder, and mix the powder for 4 hours at a speed of 120r / min to obtain a mixed powder; the mixed powder is cold-pressed into a billet with a cold-pressing mold, and the cold-pressed During the process, the pressure is 300MPa, and the holding time is 30s, and the billet is cold-pressed into a billet; the billet formed by cold pressing is put into a Φ35 graphite crucible, and then put together into an atmosphere-protected hot-press furnace, and the temperature is raised from room temperature to 900 °C at 20 °C / min. ℃, hold for 30min, then heat at 10°C / min to 1000°C, hold for 30min, pressurize 7MPa, and finally cool to room temperature with the furnace to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com