Direct sodium borohydride fuel cell anode and manufacturing method thereof

A technology of sodium borohydride and fuel cells, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of complex manufacturing process of diaphragm, low yield, high price and cost, etc., so as to improve utilization rate, improve discharge performance, suppress The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

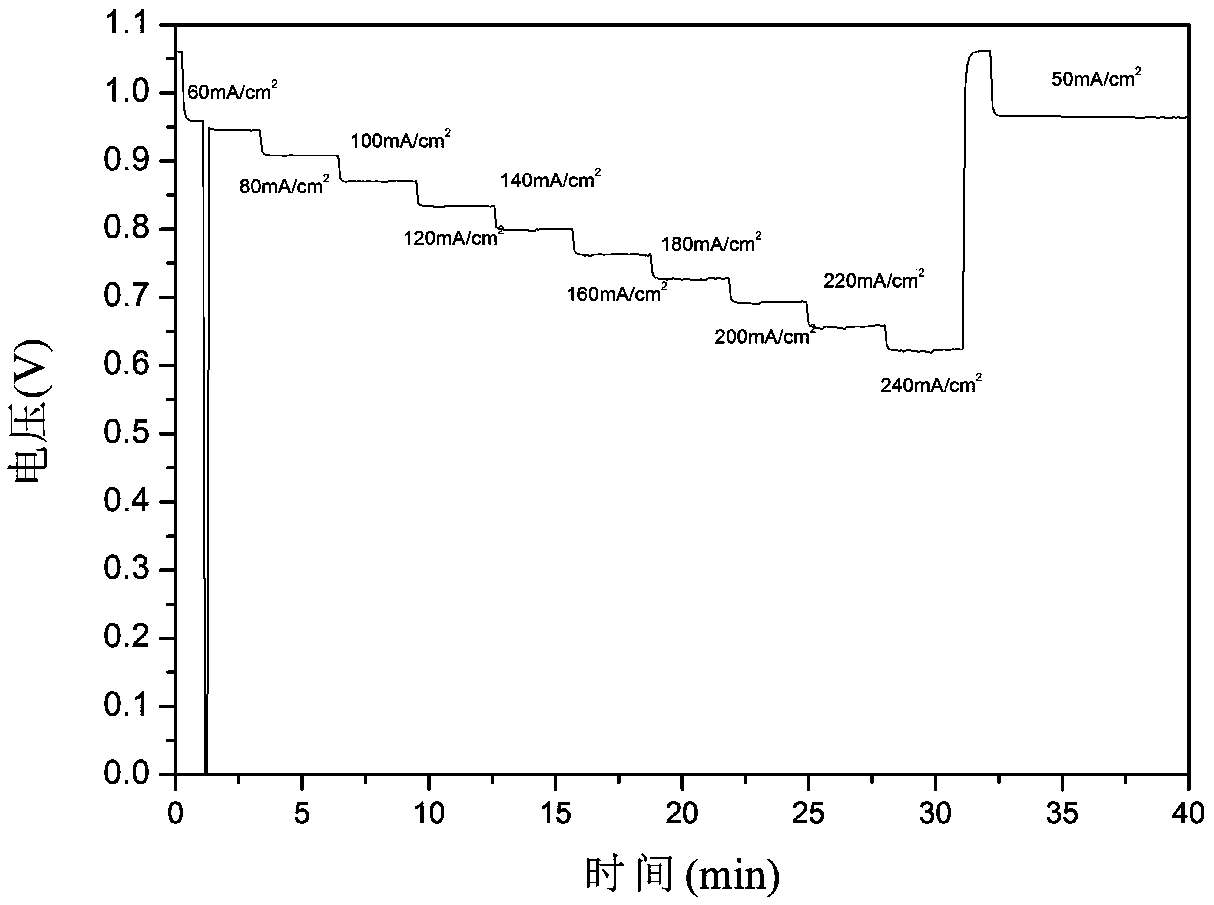

Embodiment 1

[0032] The invention relates to a manufacturing method of the anode of a direct sodium borohydride fuel cell. The method mainly prepares a catalytic slurry by mixing and stirring a certain proportion of active components and auxiliary materials, and then coats the catalytic slurry on a current collecting net.

[0033] The catalytic slurry required for making the anode of the above-mentioned direct sodium borohydride fuel cell includes the active component Co 3 o 4 、AB 5 Type hydrogen storage alloy, acetylene black and binder polyvinyl alcohol (PVA); where Co 3 o 4 The weight percentage of hydrogen storage alloy is 5%, the weight percentage of hydrogen storage alloy is 91%, acetylene black is 3%, and PVA is 1%.

[0034] Co in the above catalyst 3 o 4 (Wuxi Hengtai) has a purity of 99.9% and a specific surface area of 140m 2 / g, black powder with an average particle size of 50nm.

[0035] AB above 5 The purity of the type hydrogen storage alloy is 99.9%, the particle s...

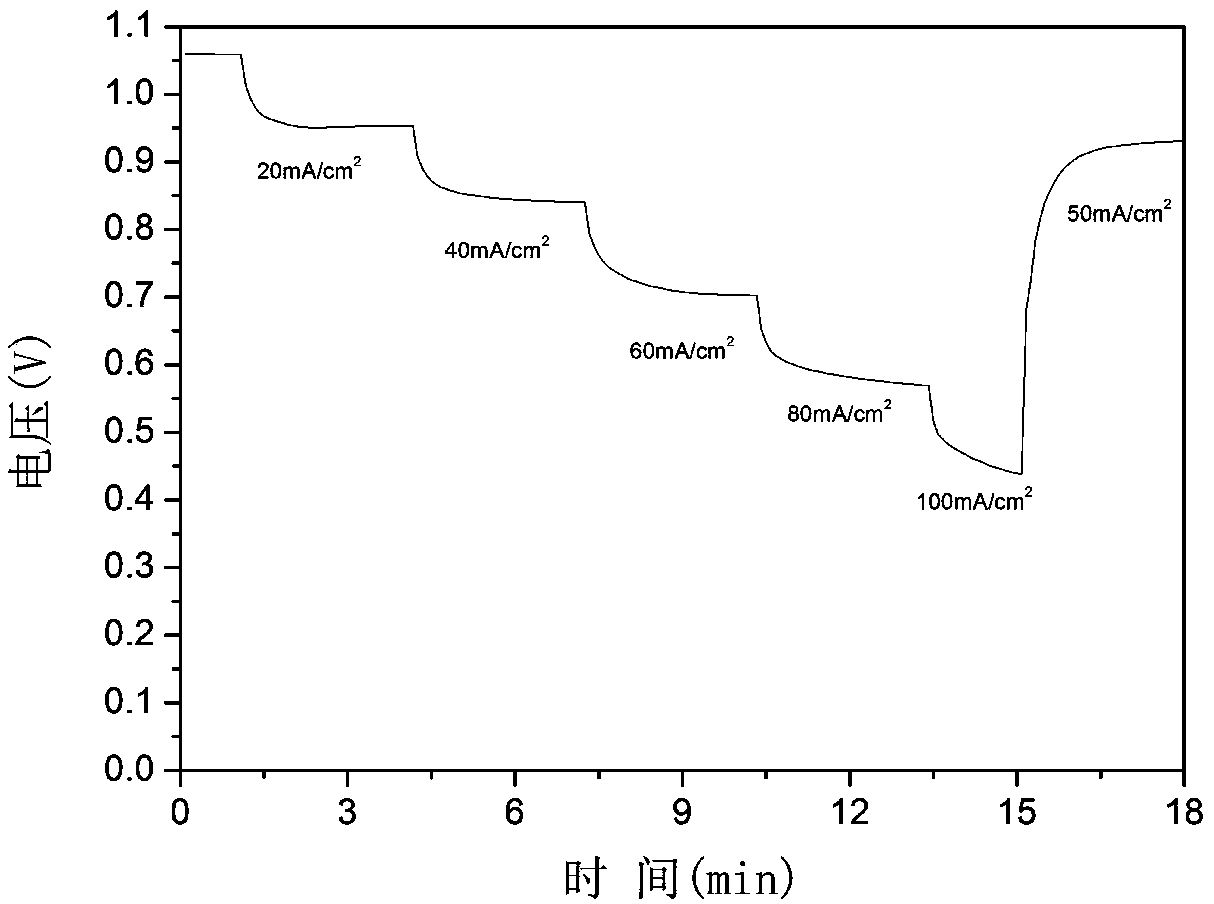

Embodiment 2

[0044] The invention relates to a manufacturing method of the anode of a direct sodium borohydride fuel cell. The method mainly prepares a catalytic slurry by mixing and stirring a certain proportion of active components and auxiliary materials, and then coats the catalytic slurry on a current collecting net.

[0045] The catalytic slurry required for making the anode of the above-mentioned direct sodium borohydride fuel cell includes the active component Co 3 o 4 、AB 5 Type hydrogen storage alloy, carbon black ( XC-72) and binder polyvinyl alcohol (PVA); where Co 3 o 4 The weight percentage of hydrogen storage alloy is 1%, the weight percentage of hydrogen storage alloy is 95%, carbon black ( XC-72) was 3%, and PVA was 1%.

[0046] Co in the above catalyst 3 o 4 (Wuxi Hengtai) has a purity of 99.9% and a specific surface area of 140m 2 / g, black powder with an average particle size of 50nm.

[0047] AB above 5 The purity of the type hydrogen storage alloy is 99.9...

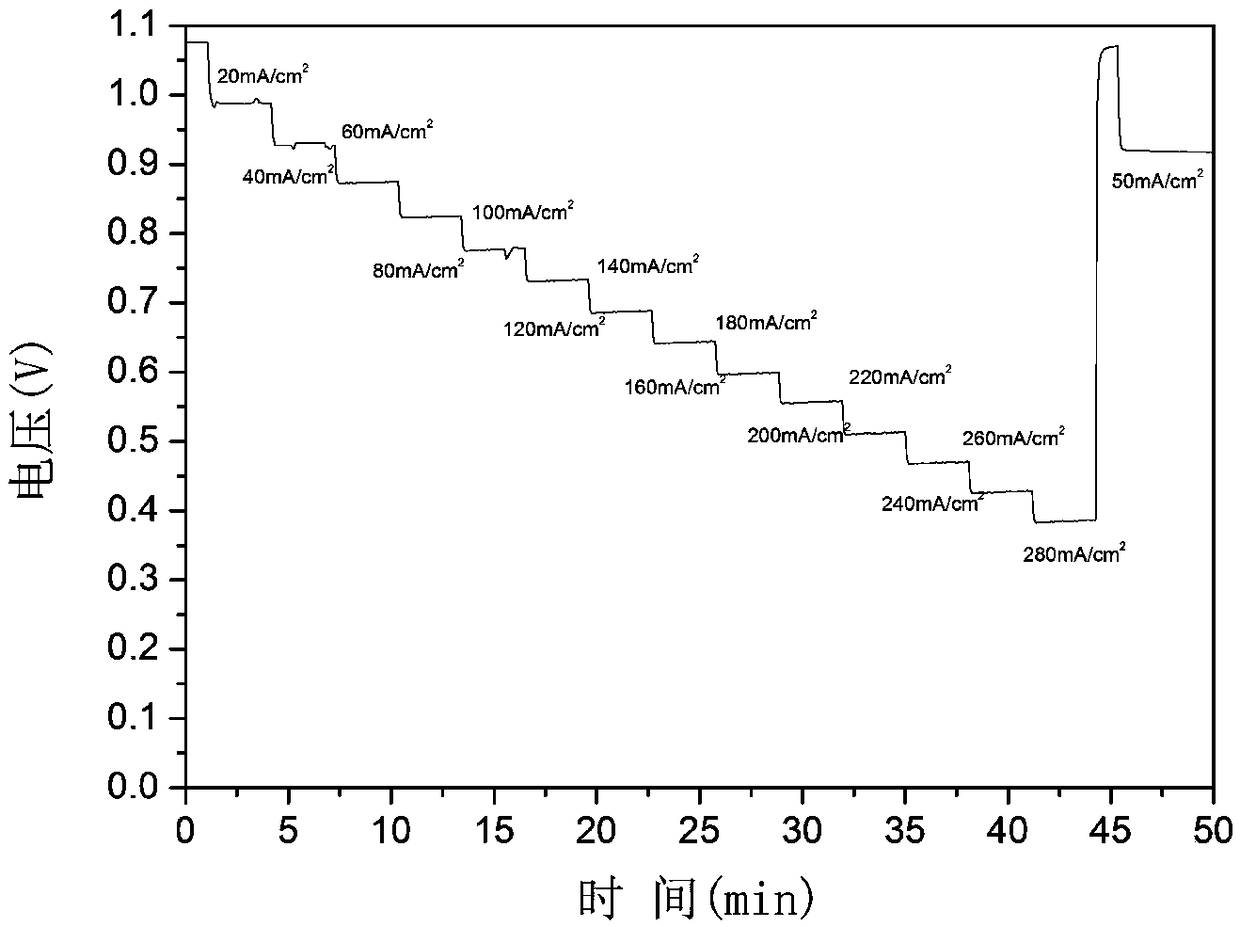

Embodiment 3

[0056] The invention relates to a manufacturing method of the anode of a direct sodium borohydride fuel cell. The method mainly prepares a catalytic slurry by mixing and stirring a certain proportion of active components and auxiliary materials, and then coats the catalytic slurry on a current collecting net.

[0057] The catalytic slurry required for making the anode of the above-mentioned direct sodium borohydride fuel cell includes the active component Co 3 o 4 、AB 5 Type hydrogen storage alloy, carbon black (BLACK 2000) and the binder carboxymethyl cellulose (CMC); where Co 3 o 4 The weight percentage of hydrogen storage alloy is 3%, the weight percentage of hydrogen storage alloy is 93%, carbon black (BLACK 2000) is 3%, and CMC is 1%.

[0058] Co in the above catalyst 3 o 4 (Wuxi Hengtai) has a purity of 99.9% and a specific surface area of 140m 2 / g, black powder with an average particle size of 50nm.

[0059] AB above 5 The purity of the type hydrogen stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com