Method for preparing photocatalyst preparation

A photocatalyst and preparation technology, applied in the field of photocatalytic materials, can solve the problems of low efficiency of organic pollutants, low solar light absorption rate, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0043] Prepare raw materials according to the proportioning in table 1:

[0044] The raw material ratio table of table 1 embodiment 1-4 and comparative example 1-3

[0045] Reagent name

Example 1

Example 2

Example 3

Example 4

Comparative example 1

Comparative example 2

Comparative example 3

La 2 Ti 2 o 7

42.86

50.00mg

52.94mg

54.55mg

52.94mg

52.94mg

52.94mg

In 2 S 3

17.14mg

10.00mg

7.06mg

5.45mg

7.06mg

7.06mg

7.06mg

La 2 Ti 2 o 7 / In 2 S 3

60.00mg

60.00mg

60.00mg

60.00mg

60.00mg

60.00mg

60.00mg

1.20mg

1.20mg

1.20mg

1.20mg

0.60mg

1.20mg

1.80mg

0.15mg

0.15mg

0.15mg

0.15mg

0.15mg

0.00mg

0.15mg

[0046] Table 2 shows the photolysis performance of Examples 1-4 and Comparative Examples 1-3 under the condition of 400nm cut-of...

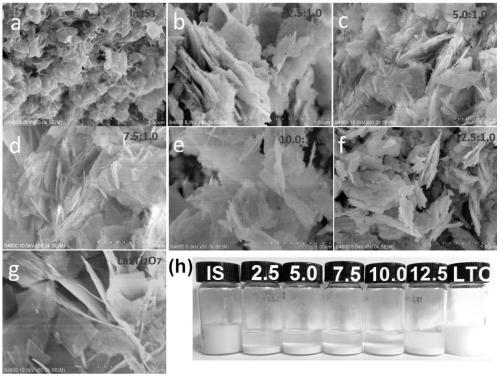

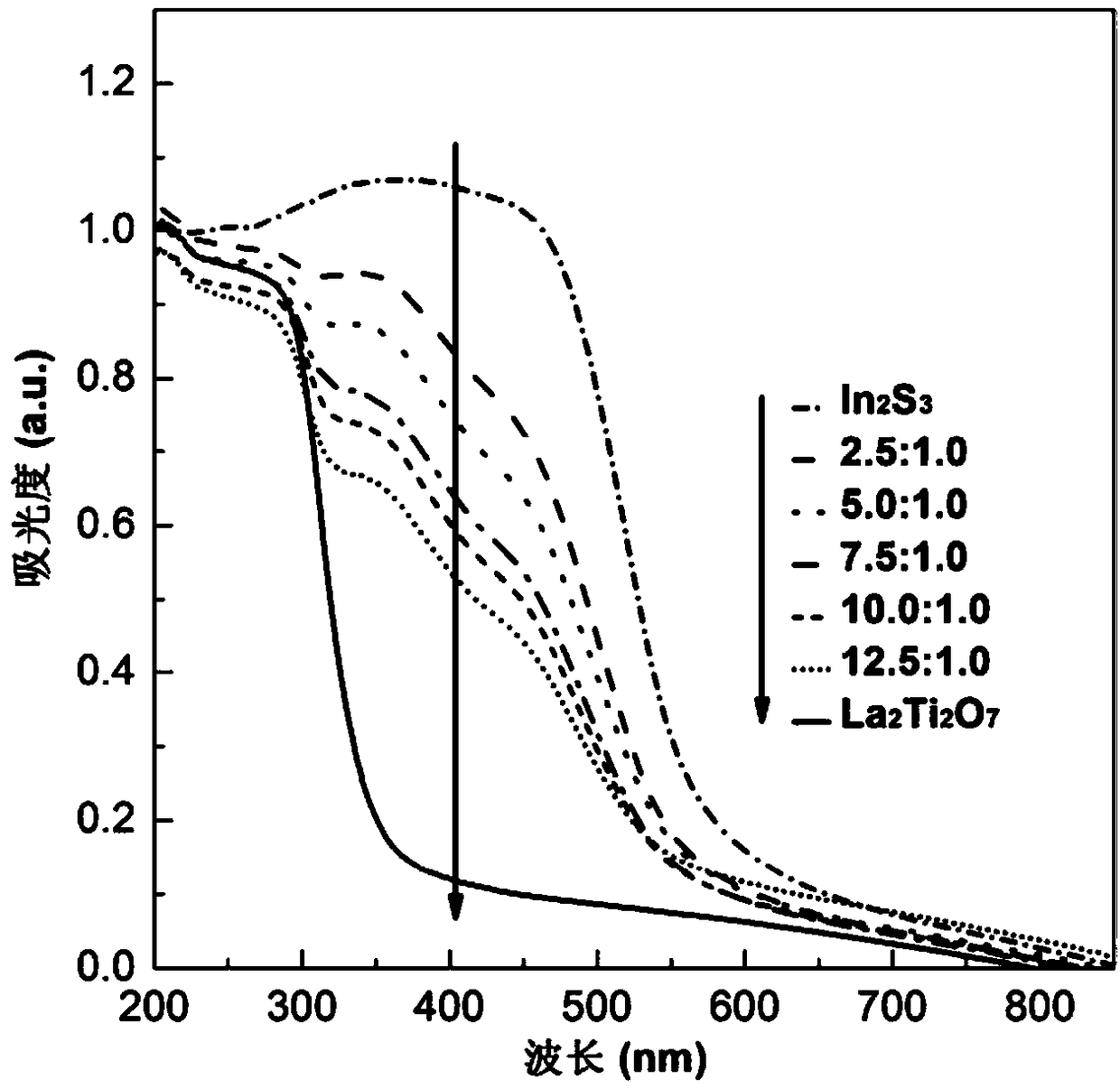

Embodiment 5

[0052] A kind of preparation method of photocatalyst preparation, perovskite type metal oxide La 2 Ti 2 o 7 with sulfide In 2 S 3 P-N heterostructure La constructed by electrostatic assembly 2 Ti 2 o 7 / In 2 S 3 , and then loaded with nano-platinum and laccase to prepare a photocatalyst preparation that can realize hydrogen production and formaldehyde degradation by solar energy. Among them, the perovskite metal oxide La 2 Ti 2 o 7 with sulfide In 2 S 3 The mass ratio of the photocatalyst preparation is 2.5:1.0, the content of loaded nano-platinum is 1wt%, and the visible light absorption of the prepared photocatalyst preparation is continuously adjustable from 500 nanometers to 600 nanometers.

[0053] The above-mentioned preparation method specifically adopts the following steps:

[0054] (1) Control the temperature at 263K, mix and dissolve titanium acetate and lanthanum nitrate in deionized water to obtain a transparent solution;

[0055] (2) Control temperat...

Embodiment 6

[0065] A kind of preparation method of photocatalyst preparation, perovskite type metal oxide La 2 Ti 2 o 7 with sulfide In 2 S 3 P-N heterostructure La constructed by electrostatic assembly 2 Ti 2 o 7 / In 2 S 3 , and then load nano-platinum and laccase to prepare a photocatalyst preparation that can realize hydrogen production by solar energy and formaldehyde degradation by solar energy, wherein the perovskite metal oxide La 2 Ti 2 o 7 with sulfide In 2 S 3 The mass ratio is 7.5:1.0, the content of loaded nano-platinum is 2wt%, and the content of laccase is 0.5wt%. The visible light absorption of the prepared photocatalyst preparation is continuously adjustable from 500 nanometers to 600 nanometers.

[0066] The above-mentioned preparation method specifically adopts the following steps:

[0067] (1) Control the temperature at 273K, mix and dissolve titanium acetate and lanthanum nitrate in deionized water to obtain a transparent solution;

[0068] (2) control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com