Preparation method of TiO2 nano tubes with controllable tube wall thickness

A nanotube and tube wall technology is applied in the field of preparation of TiO2 nanotubes with a controllable wall thickness, which can solve the problems of low utilization rate of solar energy and the like, and achieve the effects of simple method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

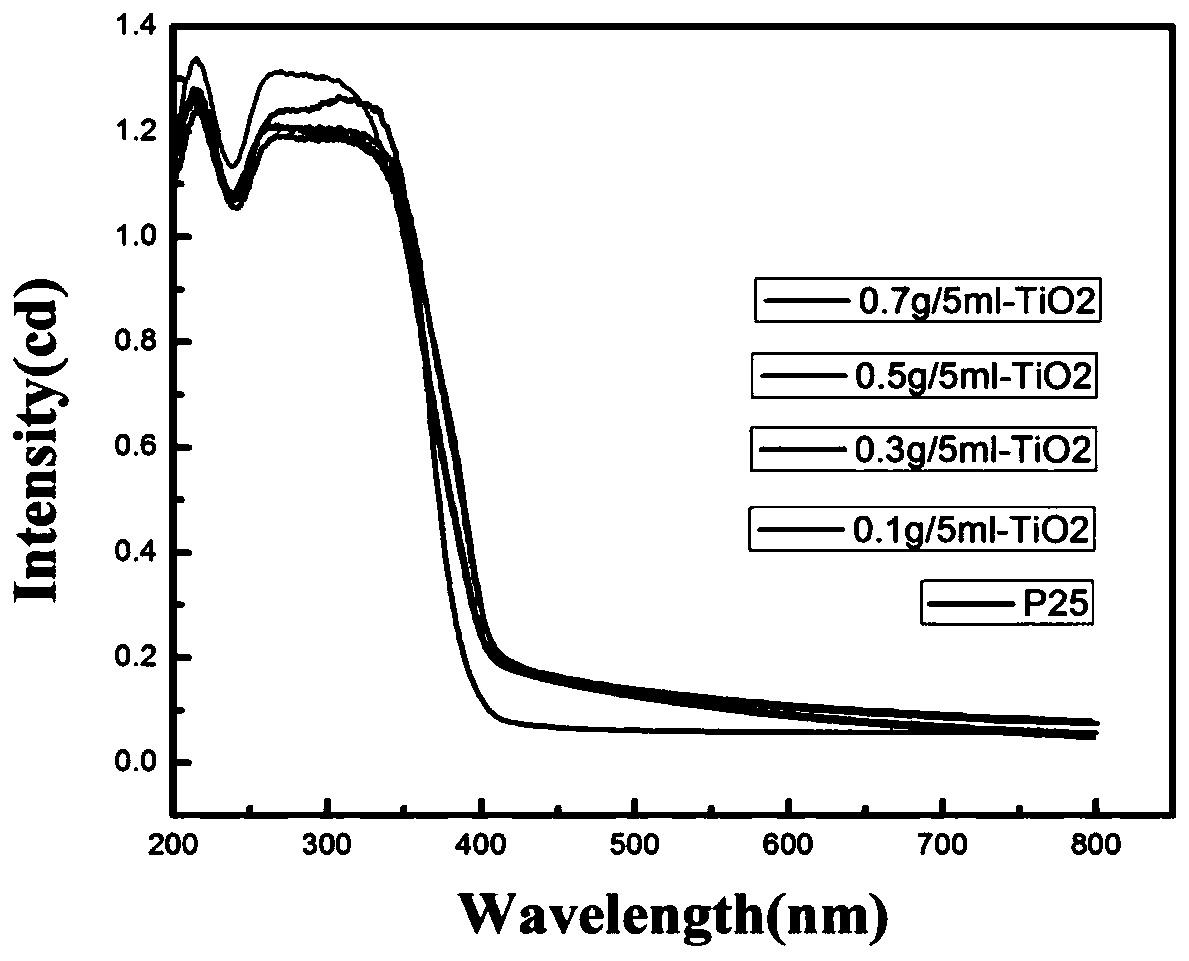

Embodiment 1

[0025] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:3, and mix well to obtain solution A;

[0026] 2) Add polyvinylpyrrolidone with a mass ratio of 8% to solution A, and completely dissolve to obtain solution B;

[0027] 3) Add liquid paraffin with a volume ratio of 2.7% to solution B, and stir for 48 hours to obtain solution C;

[0028] 4) Put solution C into a 5mL syringe, install the syringe on an electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 5mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

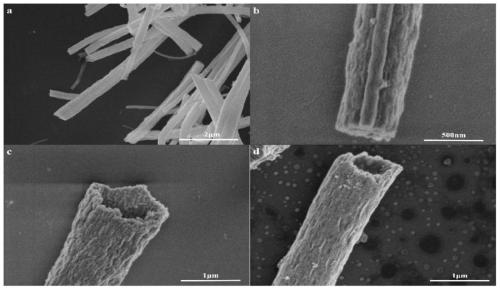

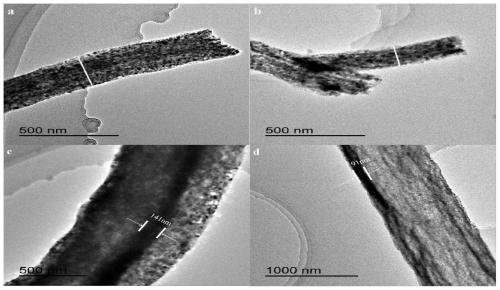

[0029] 5) After the spinning product is dried, it is calcined at 500°C in an air atmosphere to obtain TiO 2 nanotube;

Embodiment 2

[0031] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol in a volume ratio of 1:1:2, and mix well to obtain solution A;

[0032] 2) Add polyvinylpyrrolidone with a mass ratio of 10% to solution A, and completely dissolve to obtain solution B;

[0033] 3) Add liquid paraffin with a volume ratio of 7.3% to solution B, and stir for 48 hours to obtain solution C;

[0034] 4) Put solution C into a 5mL syringe, install the syringe on an electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 5mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0035] 5) After the spinning product is dried, it is calcined at 500°C in an air atmosphere to obtain TiO 2 nanotube;

Embodiment 3

[0037] 1) Add acetylacetone and tetrabutyl titanate in sequence to absolute ethanol at a volume ratio of 1:1:1, and mix them uniformly to obtain solution A;

[0038] 2) Add polyvinylpyrrolidone with a mass ratio of 12% to solution A, and completely dissolve to obtain solution B;

[0039] 3) Add liquid paraffin with a volume ratio of 12% to solution B, and stir for 48 hours to obtain solution C;

[0040] 4) Put solution C into a 5mL syringe, install the syringe on an electrospinning device, conduct electrospinning at a voltage of 18KV, a solution supply rate of 5mL / h, and a receiving distance of 20cm, and collect the product with a stainless steel plate;

[0041] 5) After the spinning product is dried, it is calcined at 500°C in an air atmosphere to obtain TiO 2 nanotube;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com