A method for preparing tantalum-based perovskite oxynitride photocatalyst

A technology of nitrogen oxides and photocatalysts, applied in the field of photocatalytic materials, can solve the problems of low efficiency of solar hydrogen production efficiency, organic pollutants, poor stability, and low sunlight absorption rate, so as to enhance the ability of coating and fixation, improve the effective The effect of separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation and use of water splitting hydrogen production photocatalyst:

[0029] The sample powder P1, cobalt nitrate, and deionized water were mixed, and the suspension M1 was obtained by ultrasonic; Burn for 1-3 hours, continue to burn for 1-3 hours under the condition of 423K-473K under the air atmosphere, and obtain powder P2; mix the powder P2 with chloroplatinic acid solution, and burn for 1-3 hours under the condition of 400K-500K, Obtain water splitting hydrogen production type photocatalyst;

[0030] Select a piece of clean FTO conductive glass (10 cm × 10 cm), mix water decomposition hydrogen production photocatalyst, polyvinylpyrrolidone (PVP, molecular weight 1300000), deionized water according to the weight ratio of 20:1:10, grind, Scratch coating on FTO conductive glass; FTO conductive glass and platinum sheet (1 cm × 1 cm) loaded with water splitting hydrogen production photocatalyst are used as working electrode and counter electrode respectively, and...

Embodiment 1-4

[0035] Preparation of perovskite metal oxynitride LaTa according to different La / Zr ratios in Table 1 1-x Zr x o 1+y N 2-y and performance testing

[0036] Table 1

[0037] Reagent name Example 1 Example 2 Example 3 Example 4 x 0.05 0.10 0.15 0.20 Zirconium acetate 2.01 4.03 6.06 8.09 Lanthanum nitrate hexahydrate 53.20 53.30 53.41 53.51 Tantalum pentachloride 41.79 39.67 37.53 35.40 Chloroplatinic acid 1.00 1.00 1.00 1.00 cobalt nitrate 2.00 2.00 2.00 2.00 Silver nitrate 0.00 0.00 0.00 0.00 Laccase 0.00 0.00 0.00 0.00

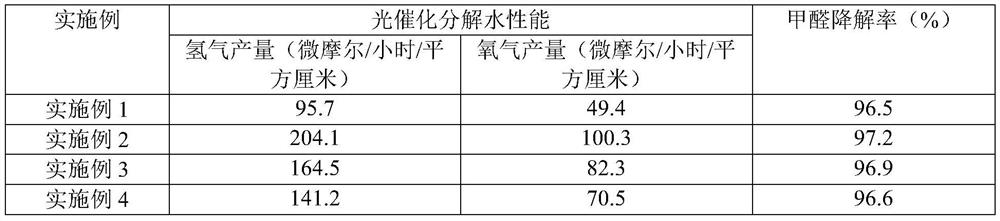

[0038] Table 2 prepares LaTa for different La / Zr ratios 1-x Zr x o 1+y N 2-y In Examples 1-4, the performance of photolysis of water under the condition of AM 1.5G and the detection of formaldehyde removal performance according to GB / T16129.

[0039] Table 2

[0040]

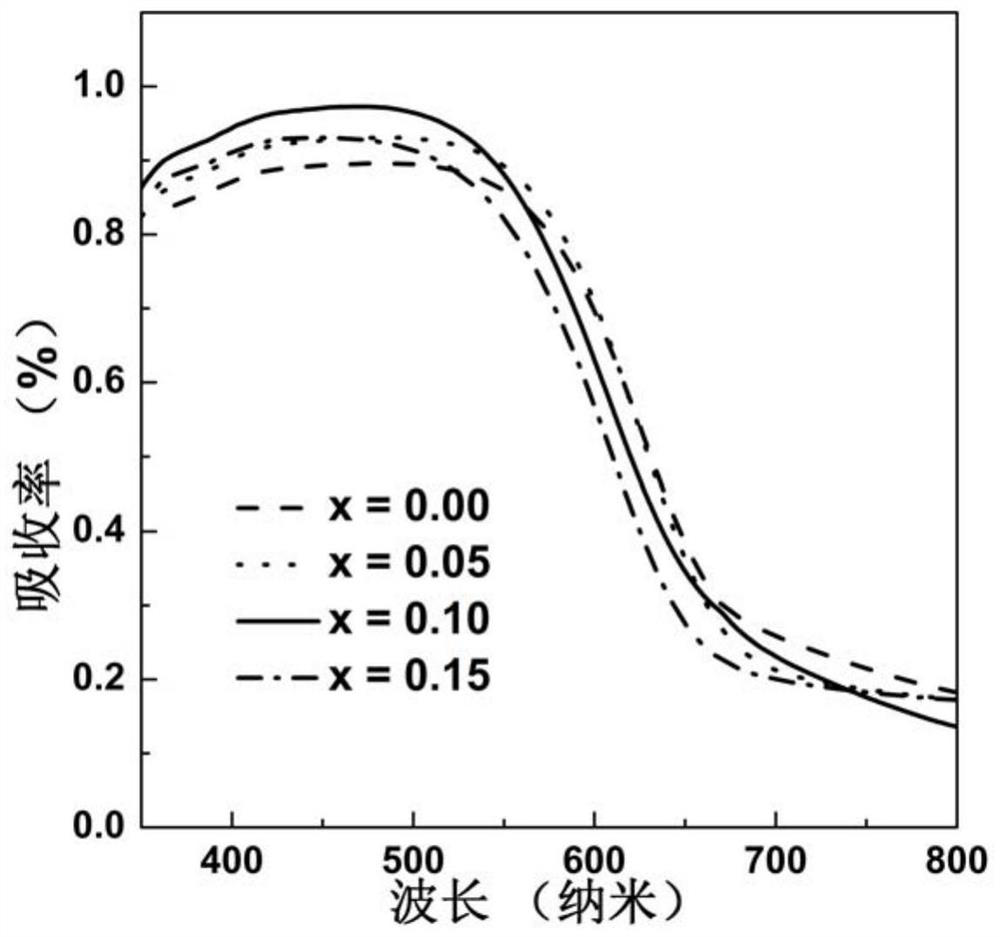

[0041] figure 1 LaTa is prepared for x=0 and Examples 1-3 1-x Zr x o 1+y N 2-y (0

Embodiment 5-9 and comparative example 1

[0043] The performance test of solar photocatalytic hydrogen production and formaldehyde degradation of different components of photocatalysts, the composition of the components is shown in Table 3.

[0044] table 3

[0045] Reagent name Example 5 Example 6 Example 7 Example 8 Example 9 Example 9 Comparative example 1 x 0.10 0.10 0.10 0.10 0.10 0.10 0.10 Zirconium acetate 4.03 4.03 4.03 4.03 4.03 4.03 4.03 Lanthanum nitrate hexahydrate 53.30 53.30 53.30 53.30 53.30 53.30 53.30 Tantalum pentachloride 39.67 39.67 39.67 39.67 39.67 39.67 39.67 Chloroplatinic acid 2.00 3.00 1.00 2.00 2.00 2.00 0.00 cobalt nitrate 4.00 6.00 0.00 4.00 4.00 4.00 0.00 Silver nitrate 0.00 0.00 2.00 0.00 0.00 0.00 0.00 Laccase 0.00 0.00 0.00 1.00 5.00 10.00 0.00

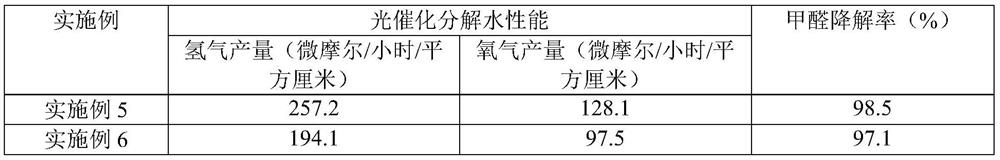

[0046] Table 4 Different La / Zr ratios prepare LaTa 1-x Zr x o 1+y N 2-y In Examples 5-9 and Comparative Example 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com