Graphene oxide/polyformaldehyde porous microsphere for reinforced master batch and preparation method of porous microsphere

A technology of reinforcing masterbatch and porous microspheres, which is applied in the field of plastic fillers, can solve the problems of low microsphere pore size, cumbersome preparation process, and difficult dispersion of graphene and other fillers, achieving large microsphere pore size, simple process, and inhibiting the tendency of agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

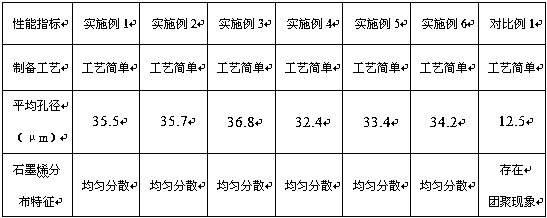

Examples

Embodiment 1

[0032] The preparation process is:

[0033] (1) Disperse graphene oxide in water, add dodecylamine, heat and ultrasonically disperse, then filter and freeze-dry to obtain functionalized graphene oxide; wherein, 7 parts by weight of graphene oxide and 92 parts by weight of water , 1 part by weight of dodecylamine; the heating temperature is 41°C, and the ultrasonic dispersion time is 2h;

[0034] (2) Add polyoxymethylene resin into diphenyl ether, stir until fully dissolved to obtain a polyoxymethylene solution, then add the functionalized graphene oxide prepared in step (1), ultrasonically disperse for 1 hour to obtain a mixed solution, and then introduce In the cooling device, put it into a cold trap for quenching treatment to obtain a gel; wherein, 36 parts by weight of polyoxymethylene resin, 59 parts by weight of diphenyl ether, and 5 parts by weight of functionalized graphene oxide; the temperature of stirring is 30 ° C, The time is 12h; the quenching temperature is 0°C,...

Embodiment 2

[0041] The preparation process is:

[0042] (1) Disperse graphene oxide in water, add dodecylamine, heat and ultrasonically disperse, then filter and freeze-dry to obtain functionalized graphene oxide; wherein, 6 parts by weight of graphene oxide and 93 parts by weight of water 1 part by weight of dodecylamine; the heating temperature is 38°C, and the ultrasonic dispersion time is 3h;

[0043] (2) Add polyoxymethylene resin into diphenyl ether, stir until fully dissolved to obtain a polyoxymethylene solution, then add the functionalized graphene oxide prepared in step (1), ultrasonically disperse for 1 hour to obtain a mixed solution, and then introduce In the cooling device, put it into a cold trap for quenching treatment to obtain a gel; wherein, 30 parts by weight of polyoxymethylene resin, 67 parts by weight of diphenyl ether, and 3 parts by weight of functionalized graphene oxide; the temperature of stirring is 30 ° C, The time is 11h; the quenching temperature is 0°C, a...

Embodiment 3

[0050] The preparation process is:

[0051] (1) Disperse graphene oxide in water, add dodecylamine, heat and ultrasonically disperse, then filter and freeze-dry to obtain functionalized graphene oxide; wherein, 8 parts by weight of graphene oxide and 90 parts by weight of water , 2 parts by weight of dodecylamine; the heating temperature is 43°C, and the ultrasonic dispersion time is 1h;

[0052] (2) Add polyoxymethylene resin into diphenyl ether, stir until fully dissolved to obtain a polyoxymethylene solution, then add the functionalized graphene oxide prepared in step (1), ultrasonically disperse for 1 hour to obtain a mixed solution, and then introduce In the cooling device, put it into a cold trap for quenching treatment to obtain a gel; wherein, 40 parts by weight of polyoxymethylene resin, 52 parts by weight of diphenyl ether, and 8 parts by weight of functionalized graphene oxide; the temperature of stirring is 30 ° C, The time is 13h; the quenching temperature is 0°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com