Preparation method of halogen-free flame-retardant dynamic vulcanized rubber waterproof coiled material

A technology of dynamically vulcanized rubber and waterproof coiled material, applied in the production of bulk chemicals, etc., can solve the problems of incapable of continuous production, poor real-time monitoring ability, poor flame retardant effect, etc., to achieve stable product quality, good environmental protection performance, The effect of real-time monitoring of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

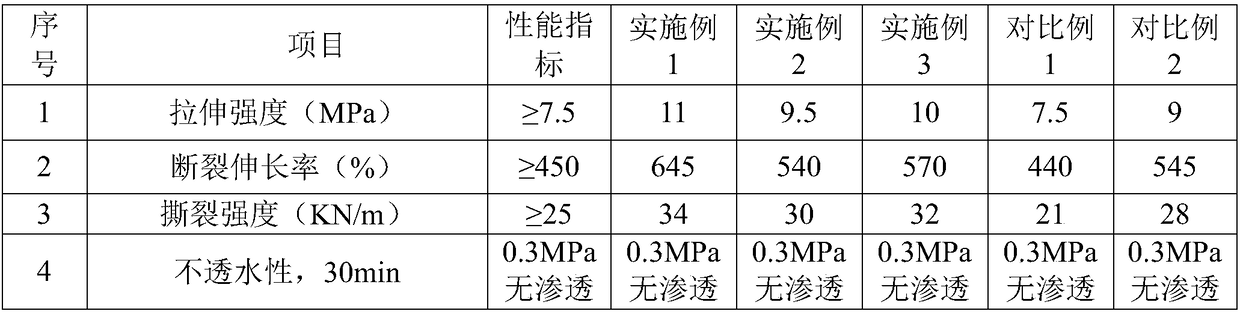

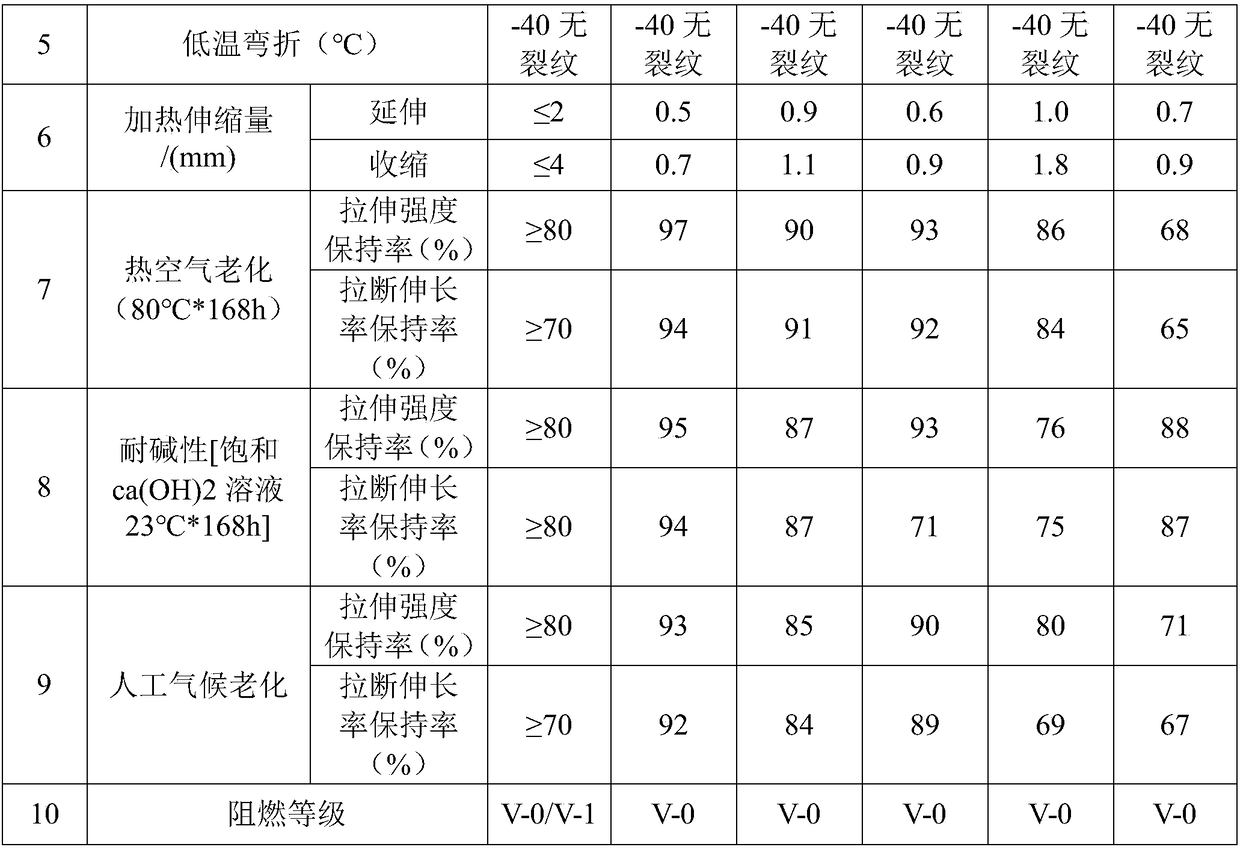

Examples

Embodiment 1

[0034] A method for preparing a dynamic vulcanized rubber waterproof coiled material, comprising the steps of:

[0035](1) Mix 20 parts of ethylene propylene diene monomer (EPDM), 20 parts of polyethylene (PE), 5 parts of maleic anhydride grafted polyethylene (MAH-g-PE), 10 parts of coumarone resin, 5 parts of cyclo Paraffin oil (KN-4010), 0.5 part of Co, 1 part of oxidized polyethylene wax (OPE wax), 1 part of silane coupling agent (KH-550), 1 part of antioxidant 1010, 1 part of antioxidant 168, 5 Parts of titanium dioxide are added to the first twin-screw extruder through weight loss weighing in proportion, plasticized, sheared, kneaded, extruded into strands and pelletized, and the barrel temperature of the first twin-screw extruder is controlled at 170-210°C , The temperature of the screen changer is controlled at 210°C, the temperature of the connecting body is controlled at 210°C, the temperature of the flange is controlled at 210°C, the temperature of the metering pump ...

Embodiment 2

[0039] A method for preparing a dynamic vulcanized rubber waterproof coiled material, comprising the steps of:

[0040] (1) 20 parts of ethylene propylene diene monomer (EPDM), 25 parts of polyethylene (PE), 2 parts of maleic anhydride grafted polyethylene (MAH-g-PE), 5 parts of coumarone resin, 5 parts of cyclo Paraffin oil (KN-4010), 0.5 part of Co, 1 part of oxidized polyethylene wax (OPE wax), 1 part of silane coupling agent (KH-550), 1 part of antioxidant 1010, 1 part of antioxidant 168, 5 Parts of titanium dioxide are added to the first twin-screw extruder through weight loss weighing in proportion, plasticized, sheared, kneaded, extruded into strips and pelletized, and the barrel temperature of the first twin-screw extruder is controlled at 180-210°C , The temperature of the screen changer is controlled at 215°C, the temperature of the connecting body is controlled at 215°C, the temperature of the flange is controlled at 215°C, the temperature of the metering pump is co...

Embodiment 3

[0044] A method for preparing a dynamic vulcanized rubber waterproof coiled material, comprising the steps of:

[0045] (1) 30 parts of EPDM, 20 parts of polyethylene (PE), 10 parts of maleic anhydride grafted polyethylene (MAH-g-PE), 8 parts of coumarone resin, 10 parts of cyclo Paraffin oil (KN-4010), 1 part of Co, 3 parts of oxidized polyethylene wax (OPE wax), 3 parts of silane coupling agent (KH-550), 1.5 parts of antioxidant 1010, 1.5 parts of antioxidant 168, 10 Parts of titanium dioxide are added to the first twin-screw extruder through weight loss weighing in proportion, plasticized, sheared, kneaded, extruded into strands and pelletized, and the barrel temperature of the first twin-screw extruder is controlled at 170-210°C , The temperature of the screen changer is controlled at 210°C, the temperature of the connecting body is controlled at 210°C, the temperature of the flange is controlled at 210°C, the temperature of the metering pump is controlled at 210°C, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com