Rolling method for controlling Nb-Ti composite precipitate in pipeline steel

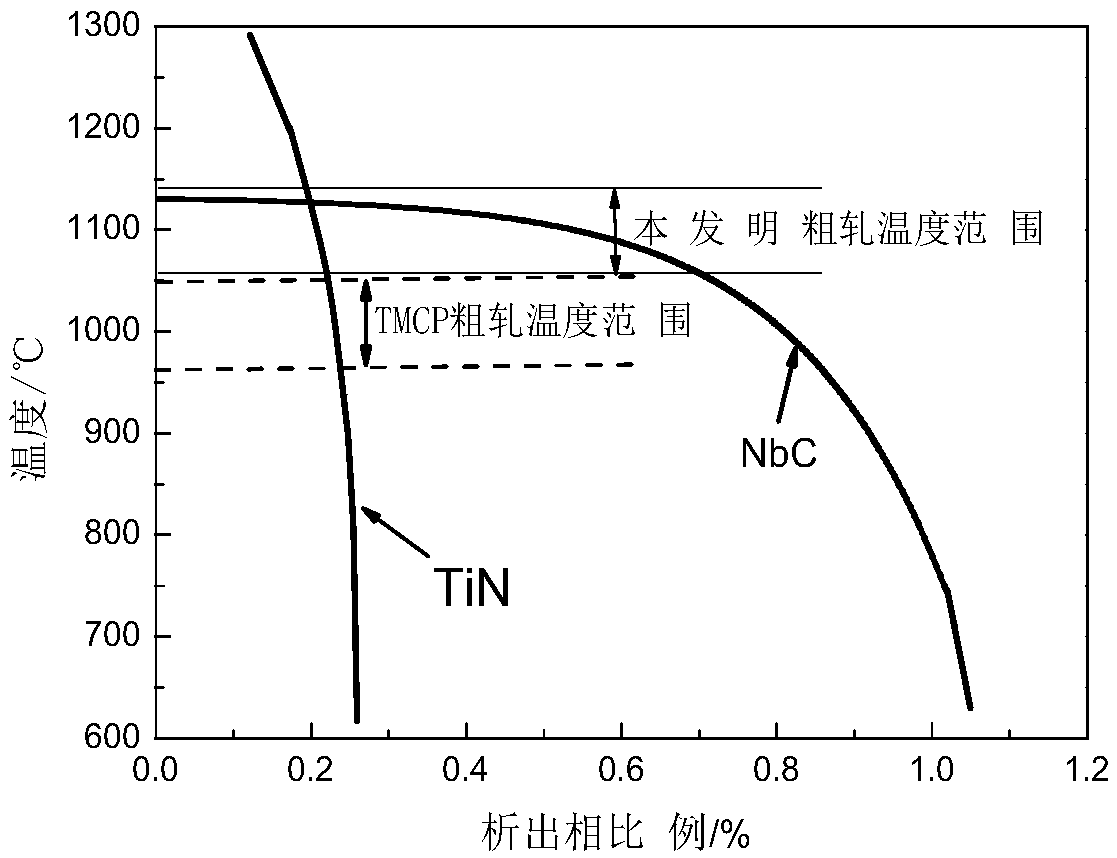

A technology for precipitates and pipeline steel, which is applied in metal rolling, metal rolling, rolling mill control devices, etc. Precipitation rules and other issues to achieve the effect of refining grains and improving toughness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The heating temperature of the continuous casting slab is 1200°C, the thermal insulation coefficient is 0.9min / mm, the rough rolling entrance temperature is 1150°C, the rough rolling single-pass reduction is 20%, and the compression ratio is 2.5; the finish rolling entrance is 950°C, and the final rolling temperature is 780°C. The compression ratio is 4.6; the cooling start temperature is 740°C, the cooling rate is 20°C / s, and the final cooling temperature is 400°C.

comparative example 2

[0043] The heating temperature of the continuous casting slab is 1200°C, the thermal insulation coefficient is 0.9min / mm, the rough rolling entrance temperature is 1050°C, the rough rolling single-pass reduction is 20%, and the compression ratio is 2.5; the finish rolling entrance is 950°C, and the final rolling temperature is 780°C. The compression ratio is 4.6; the cooling start temperature is 740°C, the cooling rate is 20°C / s, and the final cooling temperature is 400°C.

[0044] Implementation Effect:

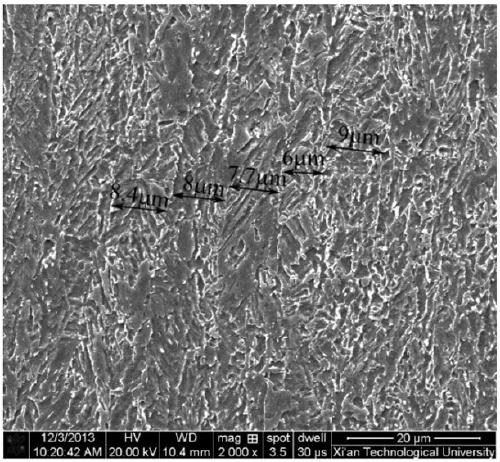

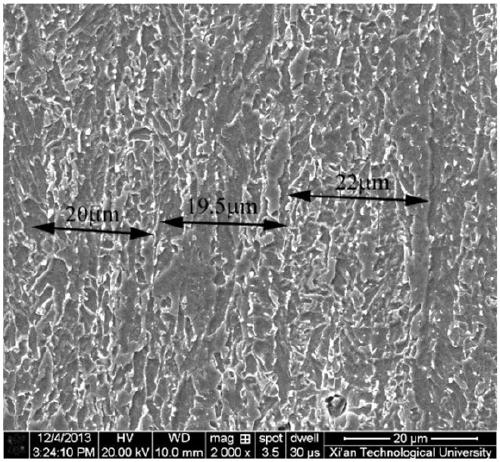

[0045]The microstructure analysis of the steel plate after rolling is carried out. The cross-section of the steel plate is taken, and after grinding and polishing, it is eroded by 4% nitric acid alcohol, and the width of the original flattened austenite is measured under the FEI scanning electron microscope. The measurement results are shown in Figure 2 ( As shown in a, b, and c), the average thickness of prior austenite grains in the embodiment of the present invention is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com