Method and device for rapidly detecting moisture content of wood chips

A detection method and technology of moisture content, applied in the direction of measuring device, weighing by removing certain components, instruments, etc., can solve the problems of fast detection of wood moisture content, etc., and achieve shortening detection time, accelerating diffusion, property stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

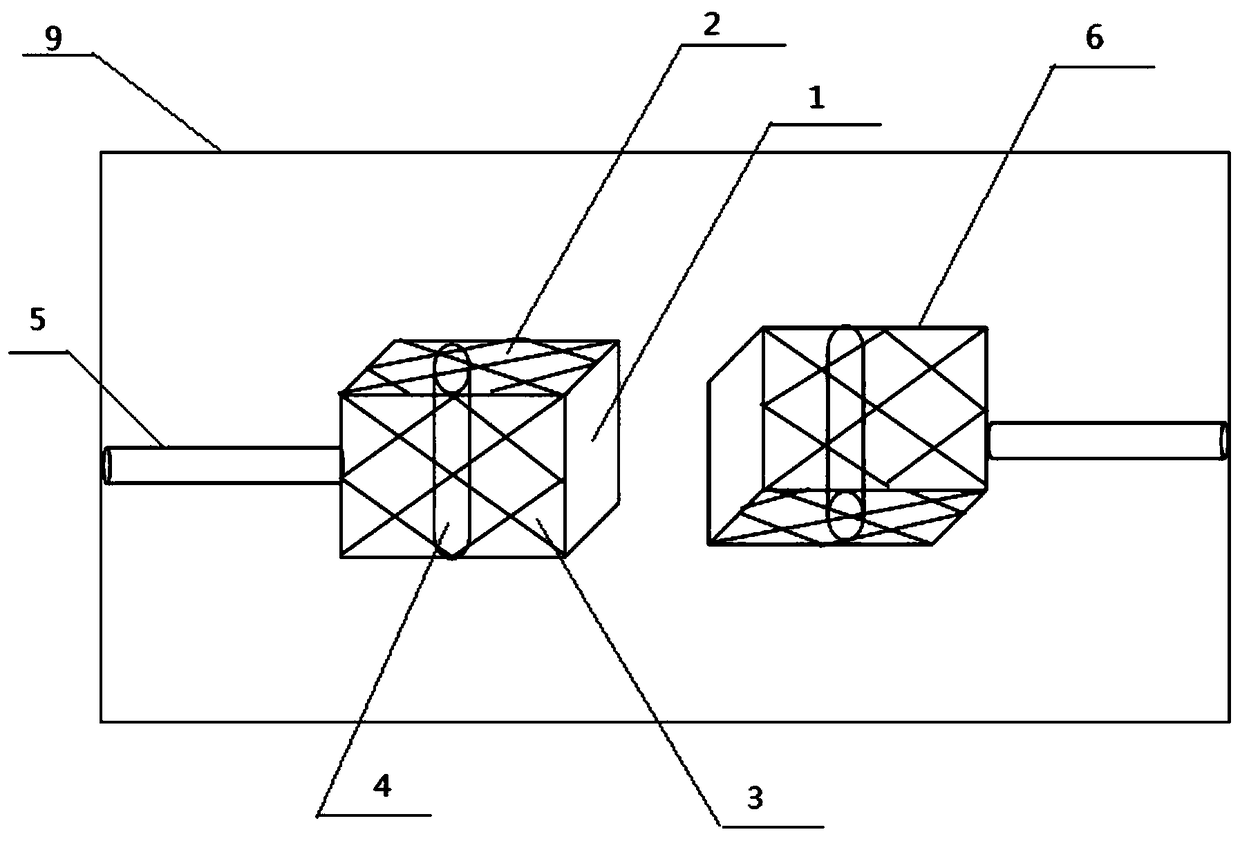

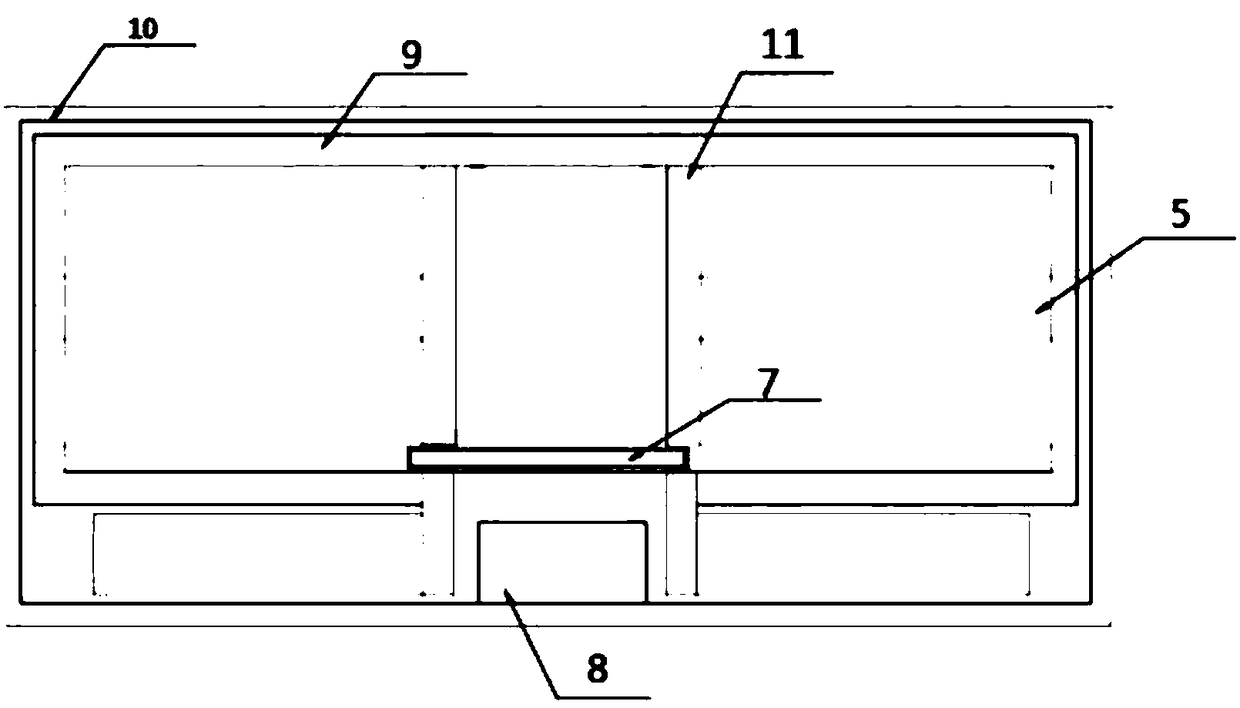

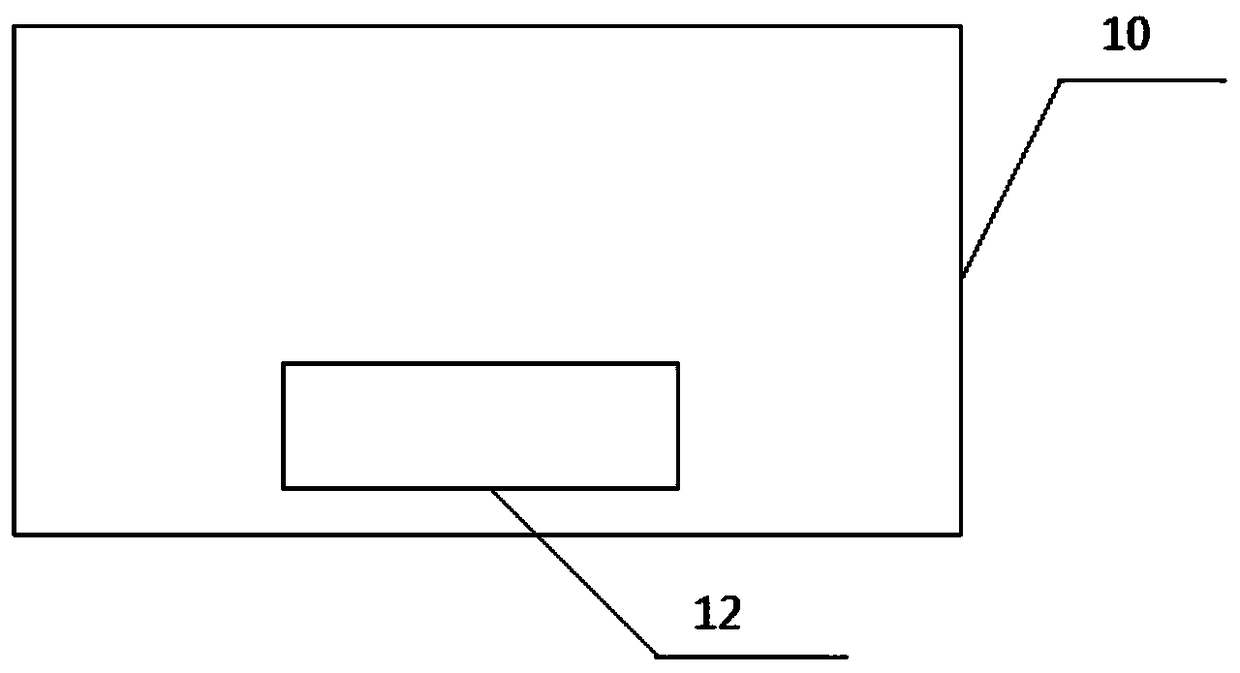

Method used

Image

Examples

Embodiment 1

[0023] Select a whole piece of wood without defects such as skin, knots, decay, moth-eaten, etc., saw off the 250mm wood at both ends of the wood chip, and then saw off the remaining wood chips at both ends to obtain 3 30mm cube wood chips. After scraping off the burrs and sawdust, weigh their mass on a balance with an accuracy of 0.01g and a range of not less than 200g, and record the mass as M, and the mass of the three test pieces corresponds to M respectively. 1 , M 2 , M 3 , and then put the test piece and the attapulgite with 10 times the weight of the test piece into the drying box to ensure that the test piece and the attapulgite are placed in different positions in the drying box so that they do not get along directly. Set the temperature of the drying oven to 100 °C, dry for about 4 hours, take out the weighing mass, record it, and then put it back into the drying oven to continue drying. Then weigh it every 1h until the last two weighings remain unchanged, which i...

Embodiment 2

[0025] Select a whole piece of wood without defects such as skin, knots, decay, moth-eaten, etc., saw off 280mm wood at both ends of the wood chip, and then saw off the remaining wood chips at both ends to obtain 3 35mm cube wood chips. After scraping off the burrs and sawdust, weigh their mass on a balance with an accuracy of 0.01g and a range of not less than 200g, and record the mass as M, and the mass of the three test pieces corresponds to M respectively. 1 , M 2 , M 3 , and then put the test piece and the attapulgite with 12 times the weight of the test piece into the drying box to ensure that the test piece and the attapulgite are placed in different positions in the drying box, so that the two do not get along directly. Set the drying oven temperature to 105°C, dry for about 4 hours, take out the weighing mass, record it, and then put it back in the oven to continue drying. Then weigh it every 1h until the last two weighings remain unchanged, which is the absolute dr...

Embodiment 3

[0027] Select a whole piece of wood without defects such as skin, knots, decay, moth-eaten, etc., saw the 300mm wood at both ends of the wood chip, and then saw off the remaining wood chips at both ends to obtain 3 40mm cube wood chips, and cut the test pieces. After scraping off the burrs and sawdust, weigh their mass on a balance with an accuracy of 0.01g and a range of not less than 200g, and record the mass as M, and the mass of the three test pieces corresponds to M respectively. 1 , M 2 , M 3 , and then put the test piece and the attapulgite with 15 times the weight of the test piece into the drying box to ensure that the test piece and the attapulgite are placed in different positions in the drying box so that they do not get along directly. Set the drying oven temperature to 110°C, dry for about 4 hours, take out the weighing mass, record it, and then put it back in the oven to continue drying. Then weigh it every 1h until the last two weighings remain unchanged, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com