Method for producing radioactive isotopes in a fast neutron reactor

A radionuclide and fast neutron technology, applied in the field of nuclear engineering, can solve the problems of rising product cost, large assembly weight, and reduced capacity, and achieve the effect of reducing materials, reducing weight, and simplifying use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

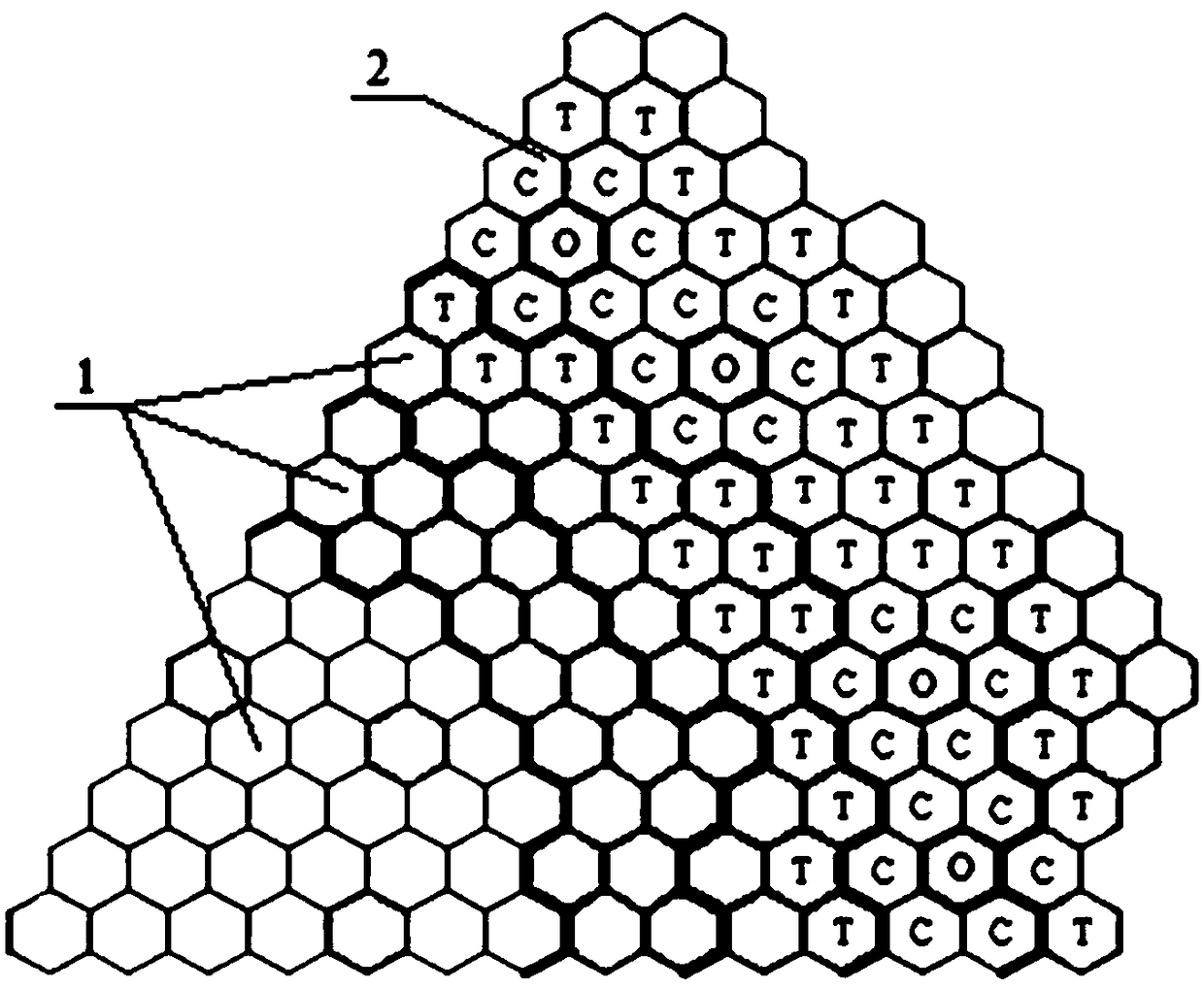

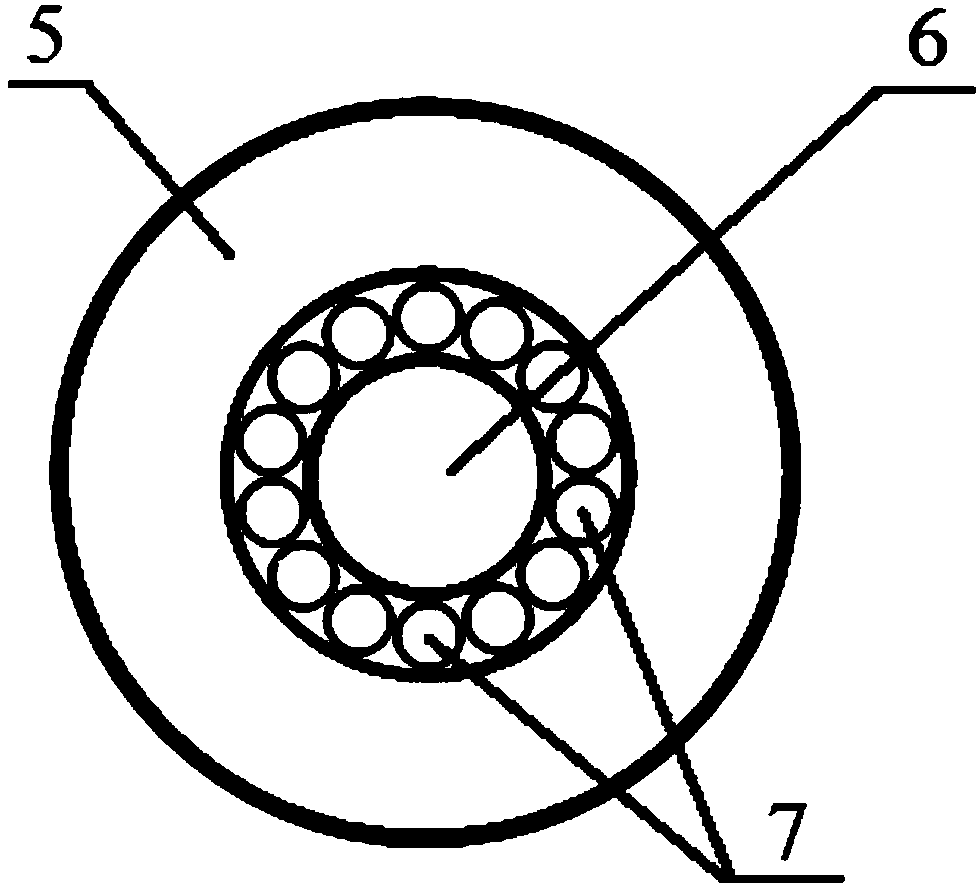

[0032] The method is implemented in a fast neutron reactor, which has an outer shell in which the core 1 and wall tubes 2 are located (see figure 1 ). In the core there are fuel assemblies used to generate the fast neutron flux. Inside the wall tubes of the reactor are the fuel assemblies used to produce plutonium and reduce the neutron flux, preventing the neutron flux from escaping the reactor.

[0033] In order to implement the method according to the invention, a radiant assembly is installed in the wall duct 2, in figure 1 The letter O is used to indicate the radiation component. The radiant assemblies are installed in the fuel assemblies denoted by the letter T and are separated from them by an intermediate steel assembly marked with the letter C, therefore, in order to carry out the invention, the assemblies are installed as follows: the irradiated assemblies are installed in the wall tubes of the reactor, The steel assembly is located around it, and the fuel assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com