Sea-buckthorn solid beverage and preparation method thereof

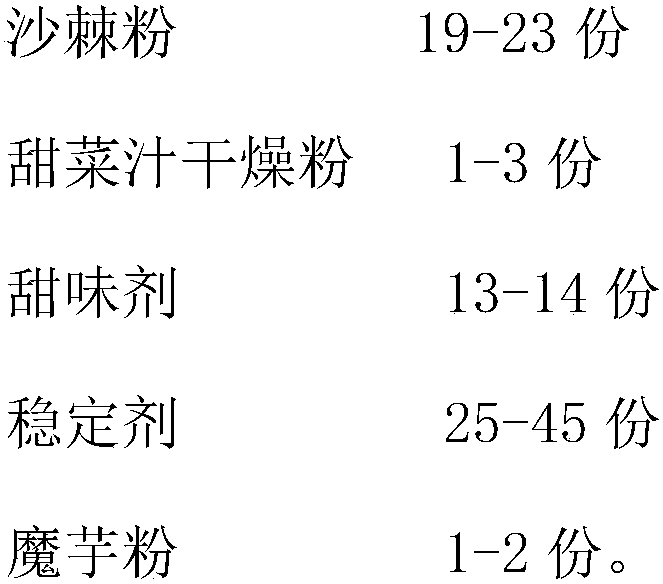

A technology of solid beverage and seabuckthorn, which is applied in the functions of food ingredients, food science, application, etc. It can solve the problems that seabuckthorn beverages cannot reflect the true orange color of seabuckthorn, limit the direct use of seabuckthorn, and the fruit of seabuckthorn is too sour, so as to achieve the effect of granulation Better, prevent colds and anemia, reduce sour and bitter taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

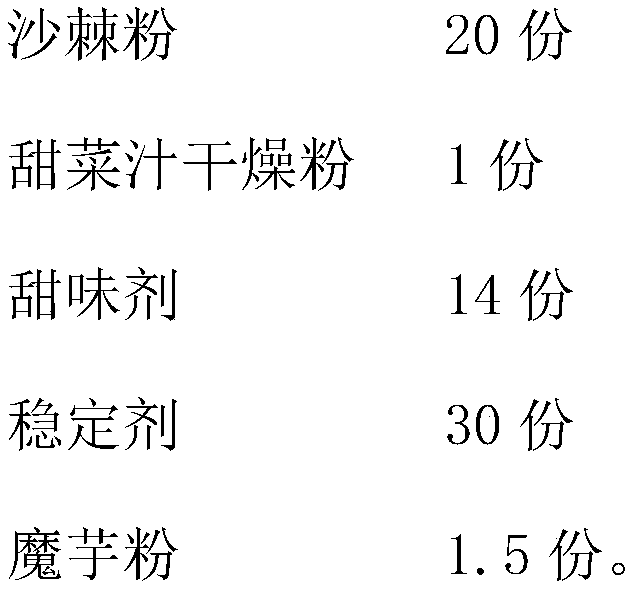

Embodiment 1

[0042] The preparation method of seabuckthorn solid drink is as follows:

[0043] 1) Raw material processing: pick and clean the fresh seabuckthorn fruits after picking, put them into plastic bottles, seal and refrigerate, clean the beets, cut them into small pieces for later use.

[0044] 2) Freeze-drying and crushing: after weighing the sea-buckthorn in a beaker, pour the sea-buckthorn into a mortar, break the pulp and core of the sea-buckthorn, remove the core, and freeze-dry (vacuum degree 40Pa, freeze-drying temperature 55°C, freeze-drying). Drying time 24h) to obtain freeze-dried seabuckthorn, and carry out superfine grinding, pass through 80 mesh sieves, obtain seabuckthorn powder; beet root grinding and take its juice and freeze-drying (vacuum degree 40Pa, freeze-drying temperature 55 ℃, freeze-drying time 24h ), carry out superfine pulverization, cross 80 mesh sieves, obtain beet juice dry powder;

[0045] 3) Preparation and addition of auxiliary materials: superfine...

Embodiment 2

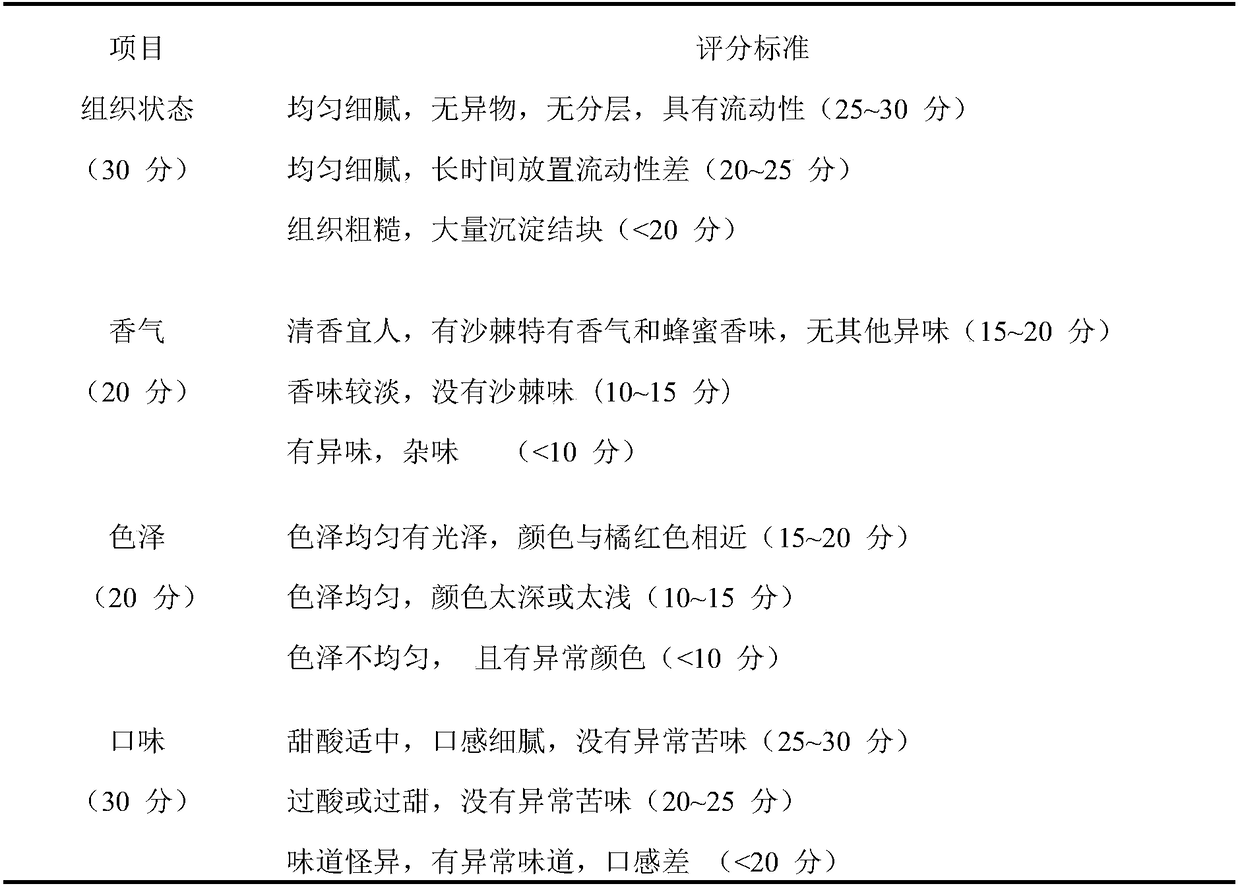

[0064] The applicant used the preparation process described in Example 1 to carry out multiple groups of experiments according to different formulations, recorded as serial numbers 1-4, and performed sensory evaluation and texture evaluation respectively, as shown in Table 2:

[0065] Table 2

[0066]

[0067]

[0068] It can be seen from Table 2 that when the beet juice dry powder is not contained, the beverage has stratification and precipitation, which proves that the beet juice dry powder can not only have a sweetening effect, but also make the beverage more refreshing after brewing. Homogeneous, no stratification, no sedimentation at the bottom. In the actual sensory experience, after adding too much dried beet juice powder, the color of the solid particles will be orange-red. When adding 1 mass part of dried beet juice powder, the color of the solid particles will be orange-yellow to make it the same as the true color of seabuckthorn. It has a certain brightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com