Magnetic electret fiber air purifying and filtering material and preparation method

A technology of air purification and filter materials, which is applied in the field of air purification, can solve the problems of complex improvement process, poor charge storage performance, and influence on development and application, and achieve the effects of extending the movement path, slow magnetic field attenuation, and reducing direct loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

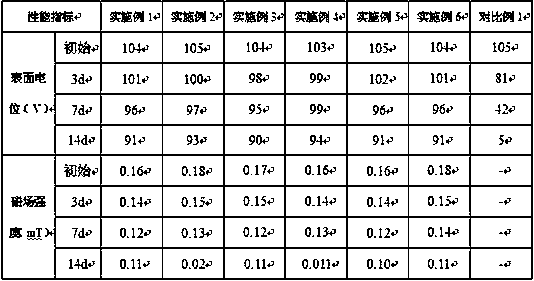

Examples

Embodiment 1

[0031] (1) Add iron salts, cobalt salts and nickel salts into deionized water and mix well to obtain a metal ion solution; the metal ion solution is a sulfate solution;

[0032] Wherein: 19 parts by weight of iron salt, 19 parts by weight of cobalt salt, 15 parts by weight of nickel salt, 47 parts by weight of deionized water;

[0033] (2) Add the metal ion solution prepared in step (1) into a miscible solution of cyclohexane, n-pentanol, cetyltrimethylammonium bromide and oxalic acid, and mix and stir at room temperature to obtain micro The emulsion is then centrifuged, dried, and calcined to obtain magnetic nanowire powder; the calcining temperature is 890°C, and the time is 1.5h;

[0034] Wherein: 43 parts by weight of metal ion solution, 43 parts by weight of cyclohexane, 3 parts by weight of n-pentanol, 4 parts by weight of cetyltrimethylammonium bromide, and 7 parts by weight of oxalic acid;

[0035] (3) Add the magnetic nanowire powder prepared in step (2) and the inor...

Embodiment 2

[0040] (1) Add iron salts, cobalt salts and nickel salts into deionized water and mix well to obtain a metal ion solution; the metal ion solution is a nitrate solution;

[0041] Wherein: 18 parts by weight of iron salt, 17 parts by weight of cobalt salt, 13 parts by weight of nickel salt, 52 parts by weight of deionized water;

[0042] (2) Add the metal ion solution prepared in step (1) into a miscible solution of cyclohexane, n-pentanol, cetyltrimethylammonium bromide and oxalic acid, and mix and stir at room temperature to obtain micro The emulsion is then centrifuged, dried, and calcined to obtain magnetic nanowire powder; the calcining temperature is 800°C, and the time is 2 hours;

[0043] Wherein: 40 parts by weight of metal ion solution, 49 parts by weight of cyclohexane, 2 parts by weight of n-pentanol, 3 parts by weight of cetyltrimethylammonium bromide, and 6 parts by weight of oxalic acid;

[0044](3) Add the magnetic nanowire powder prepared in step (2) and the in...

Embodiment 3

[0049] (1) Add iron salts, cobalt salts and nickel salts into deionized water and mix well to obtain a metal ion solution; the metal ion solution is a chloride solution;

[0050] Wherein: 22 parts by weight of iron salt, 20 parts by weight of cobalt salt, 16 parts by weight of nickel salt, 42 parts by weight of deionized water;

[0051] (2) Add the metal ion solution prepared in step (1) into a miscible solution of cyclohexane, n-pentanol, cetyltrimethylammonium bromide and oxalic acid, and mix and stir at room temperature to obtain micro The emulsion is then centrifuged, dried, and calcined to obtain magnetic nanowire powder; the calcining temperature is 1000°C, and the time is 1h;

[0052] Wherein: 45 parts by weight of metal ion solution, 36 parts by weight of cyclohexane, 4 parts by weight of n-pentanol, 5 parts by weight of cetyltrimethylammonium bromide, and 10 parts by weight of oxalic acid;

[0053] (3) Add the magnetic nanowire powder prepared in step (2) and the ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| piezoresistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com