A kind of carbon airgel and preparation method thereof

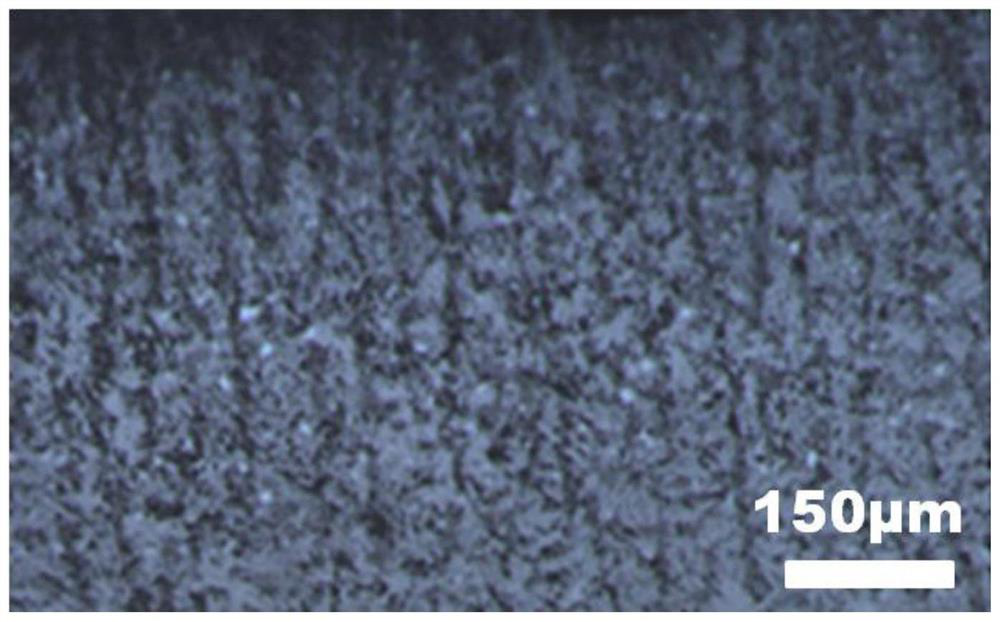

A carbon aerogel, resorcinol technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc. irregularities etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

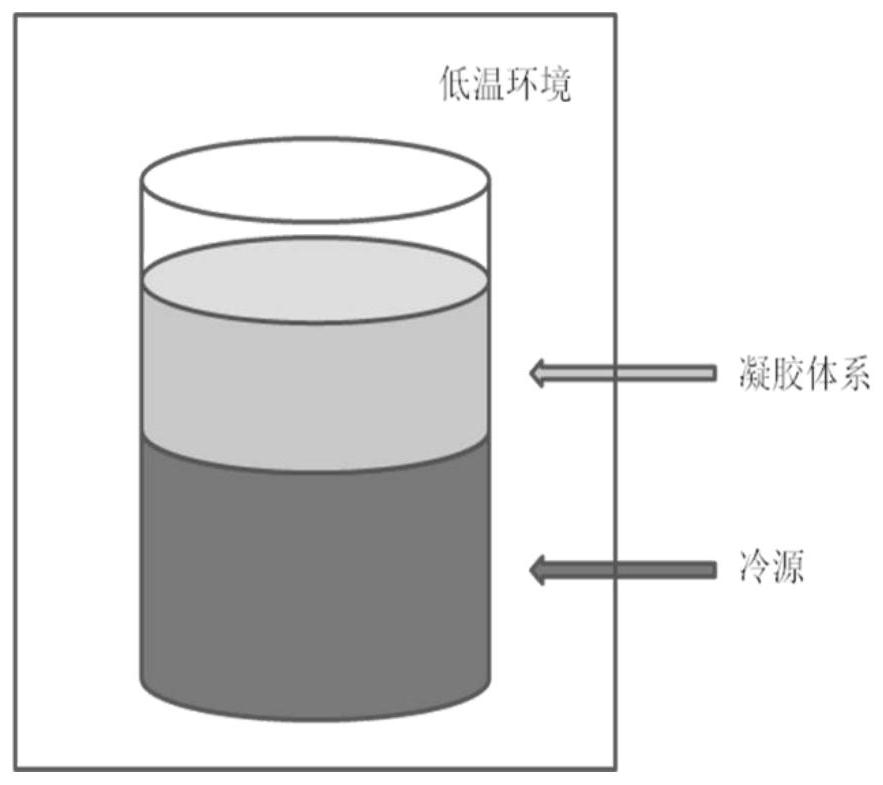

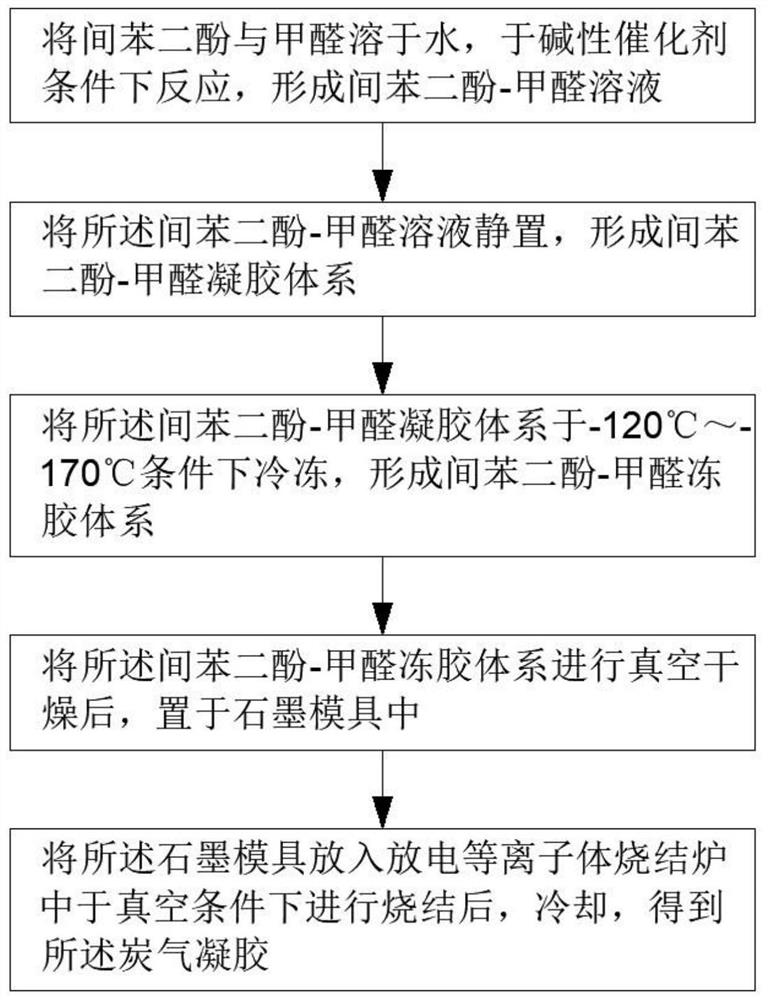

[0030] In order to solve the problem that the current preparation method of carbon aerogel has relatively large damage to the microstructure of the carbon aerogel material, thereby restricting the adsorption and filtration characteristics of the prepared carbon aerogel material, the present invention provides a carbon aerogel The preparation method, by preparing the resorcinol-formaldehyde gel system, the resorcinol-formaldehyde gel system is frozen to obtain the resorcinol-formaldehyde gel system, and then the resorcinol-formaldehyde gel system is frozen The gel system is placed in a graphite mold, sintered in a discharge plasma sintering furnace under vacuum conditions, and cooled to obtain the carbon airgel. The carbon airgel prepared by the invention has a pore structure, and the pore structure has a continuous gradient, so that the pore structure of the carbon airgel prepared by the invention is regular and orderly, thereby improving the adsorption and filtration character...

Embodiment 1

[0055] This embodiment provides a method for preparing carbon aerogel, which specifically includes the following steps:

[0056] S1: Dissolve 2g resorcinol and 8ml formaldehyde in 20ml distilled water, adjust the pH value to 7 to obtain a mixed solution;

[0057] S2: Add 0.04 g of sodium carbonate to the mixed solution, stir and react at room temperature for 1 h to obtain a resorcinol-formaldehyde solution;

[0058] S3: standing the resorcinol-formaldehyde solution at 50°C for 2 hours, and then standing at 80°C for 2 hours to form a resorcinol-formaldehyde gel system;

[0059] S4: freezing the resorcinol-formaldehyde gel system at -120°C for 1 hour to form a resorcinol-formaldehyde gel system;

[0060] S5: Vacuum-dry the resorcinol-formaldehyde jelly system at -40°C for 4 hours, and then vacuum-dry it at 150°C for 2 hours to obtain a dried resorcinol-formaldehyde jelly system;

[0061] S6: Put the dried resorcinol-formaldehyde jelly system into a graphite mold, put the graph...

Embodiment 2

[0067] Different from Example 1, the preparation method of carbon aerogel in this example includes the following steps:

[0068] S1: Dissolve 6g of resorcinol and 12ml of formaldehyde in 60ml of distilled water, and adjust the pH value to 9 to obtain a mixed solution;

[0069] S2: Add 0.7g of sodium carbonate to the mixed solution, stir and react at room temperature for 1.5h to obtain a resorcinol-formaldehyde solution;

[0070] S3: standing the resorcinol-formaldehyde solution at 50°C for 3 hours, and then standing at 80°C for 3 hours to form a resorcinol-formaldehyde gel system;

[0071] S4: freezing the resorcinol-formaldehyde gel system at -150°C for 1.5 hours to form a resorcinol-formaldehyde gel system;

[0072] S5: Vacuum-dry the resorcinol-formaldehyde jelly system at -80°C for 5 hours, and then vacuum-dry it at 180°C for 4 hours to obtain a dried resorcinol-formaldehyde jelly system;

[0073] S6: Put the dried resorcinol-formaldehyde jelly system into a graphite mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com