Preparation method of slip-proof nitrile gloves

A glove and anti-slip technology, applied in gloves, clothing, applications, etc., can solve the problems of latex damage, slag falling, and pollution of the application environment, and achieve the effects of improving anti-slip performance, good protection, and good oil-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

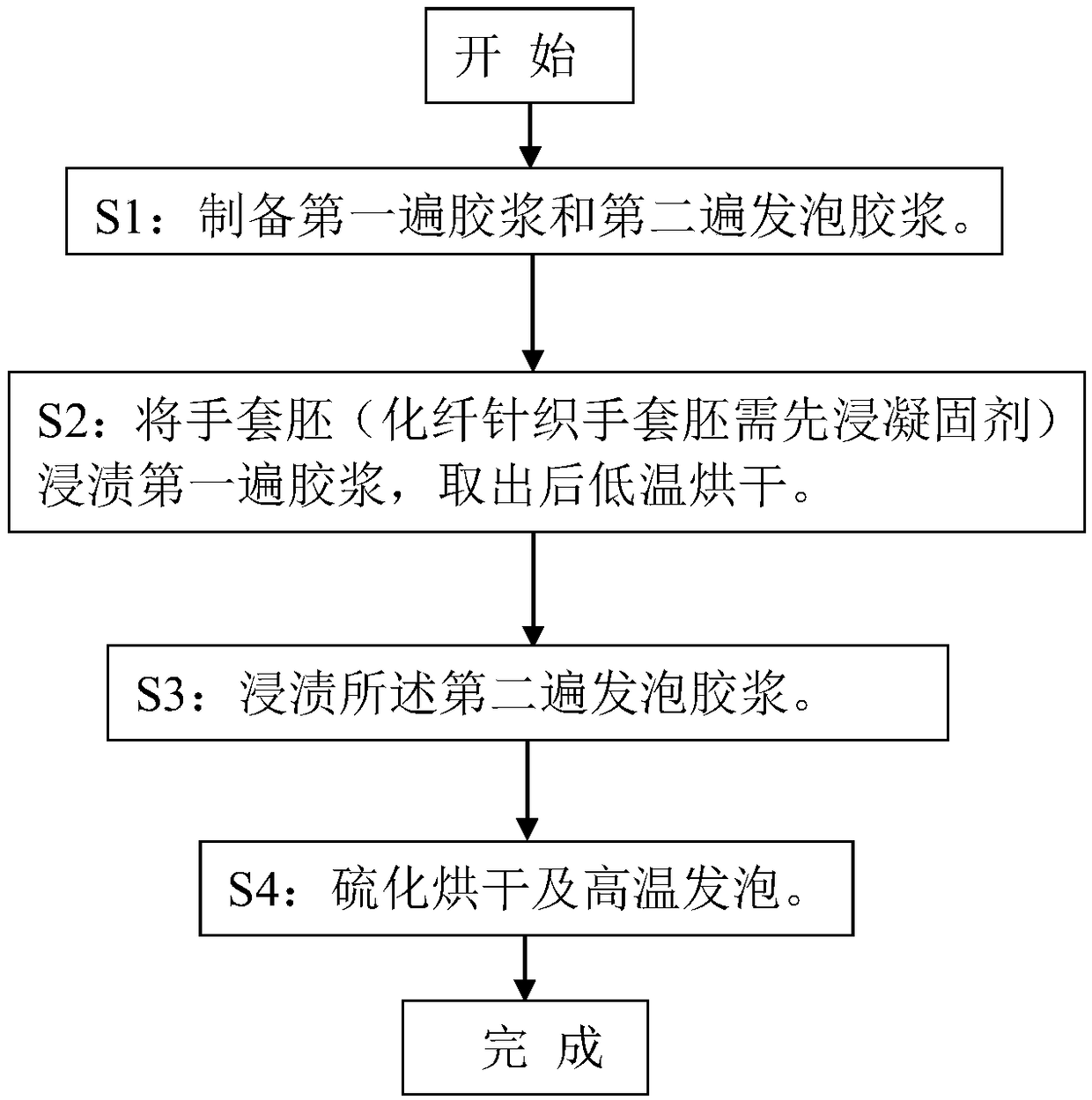

[0038] Such as figure 1 Shown, the flowchart of the preparation method of nitrile anti-skid gloves of the present invention comprises steps:

[0039] S1 Prepare the first pass of glue and the second pass of foaming glue:

[0040] Stir the mixture containing 1000 parts by mass of nitrile latex and 8 to 20 parts of thickener to obtain the first pass of glue;

[0041] The mixture containing 1000 parts by mass of nitrile latex, 1-20 parts of stabilizer, 5-20 parts of foaming agent and 2-6 parts of thickener is stirred evenly to obtain the second foaming glue. Wherein, the stabilizer and foaming agent are mixed together and then added together.

[0042] S2 One-pass dipping: dip the glove blank in the glue for the first pass, take it out and pre-dry it at low temperature to obtain the intermediate product of the glove. The low-temperature pre-baking condition is 50°C-90°C, the time is 15-30 minutes, and it is baked to 40-80% dry. In this step, a base rubber layer is formed on the...

Embodiment 1

[0048] A preparation method for nitrile non-slip gloves, comprising the steps of:

[0049] S1 Prepare the first pass of glue and the second pass of foaming glue:

[0050] A mixture of 1000 parts by mass of carboxylated nitrile latex (43% solid content) and 20 parts of thickener casein was stirred evenly to obtain the first-pass glue with a viscosity of 6000 mpa.s.

[0051] In terms of mass, after mixing 5 parts of stabilizer polyoxyethylene lauryl ether with 5 parts of foaming agent phenyl-1,-disulfonyl hydrazide and 5 parts of A-type foaming aid, add it to 1000 parts of carboxybutyronitrile Add 3 parts of thickener casein to the latex (solid content: 43%) to adjust the viscosity to 800mpa.s, and stir evenly to obtain the foaming glue for the second time.

[0052] S2 one-pass dipping: put flannelette glove embryos on the hand mold, heat the glove embryos to 35°C, impregnate the above-mentioned glue for the first pass, and pre-dry them after taking them out. The temperature of...

Embodiment 2

[0056] A preparation method for nitrile non-slip gloves, comprising the steps of:

[0057] S1 Prepare the first pass of glue and the second pass of foaming glue:

[0058] A mixture of 1000 parts by mass of carboxylated nitrile latex (43% solid content) and 8 parts of thickener casein was stirred evenly to obtain the first-pass glue with a viscosity of 1500 mpa.s.

[0059] By mass, after mixing 5 parts of stabilizer polyoxyethylene alkyl ether with 5 parts of blowing agent azodicarbonamide and 5 parts of foaming aid surface coating urea, join 1000 parts of carboxylated nitrile latex ( 43% solid content), add 3 parts of thickener sodium polyacrylate to adjust the viscosity to 600mpa.s, stir evenly to obtain the second foaming glue.

[0060] S2 one-pass dipping: put 13 needles of polyester glove blank on the hand mold, heat it, soak the coagulant at a temperature of 45°C, after the coagulant treatment, dip the above-mentioned first pass of glue, take it out, and pre-dry it . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com