Microwave dielectric ceramics and preparation method thereof

A microwave dielectric ceramic and formulation technology are applied in the field of low-loss and temperature-stable high-dielectric microwave dielectric ceramics and their preparation, which can solve the problems of difficult large-scale application and stay in the laboratory research stage, and achieve low price and good application prospects. , the effect of improving the dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

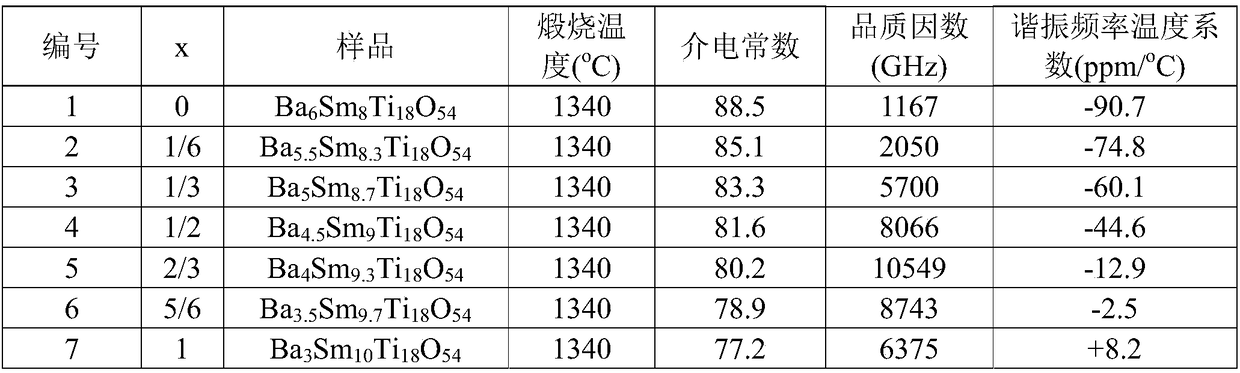

[0045] In this example, Ba with different values of x was prepared 6-3x Sm 8+2x Ti 18 O 54 , And tested its dielectric constant, quality factor and temperature coefficient of resonance frequency.

[0046] The structural formula is Ba according to the following method 6-3x Sm 8+2x Ti 18 O 54 (x=0, 1 / 6, 1 / 3, 1 / 2, 2 / 3, 5 / 6, 1) microwave dielectric ceramics:

[0047] (1) Put BaCO 3 , Sm 2 O 3 And TiO 2 Mix, fully ball mill after mixing, dry, sieved and put into corundum crucible after ball milling, then calcined at 1150℃ for 4h to obtain Ba 6-3x Sm 8+2x Ti 18 O 54 ;

[0048] (2) The Ba obtained in step (1) 6-3x Sm 8+2x Ti 18 O 54 Fully ball milling, drying, granulating, sieving after ball milling, pressing the sieved particles into a cylinder with a diameter of 10mm and a height of 6mm, and then calcining at 1340℃ for 4h to obtain microwave dielectric ceramics.

[0049] The properties of the obtained samples are shown in Table 1:

[0050] Table 1

[0051]

[0052] After comparison, it is f...

Embodiment 2

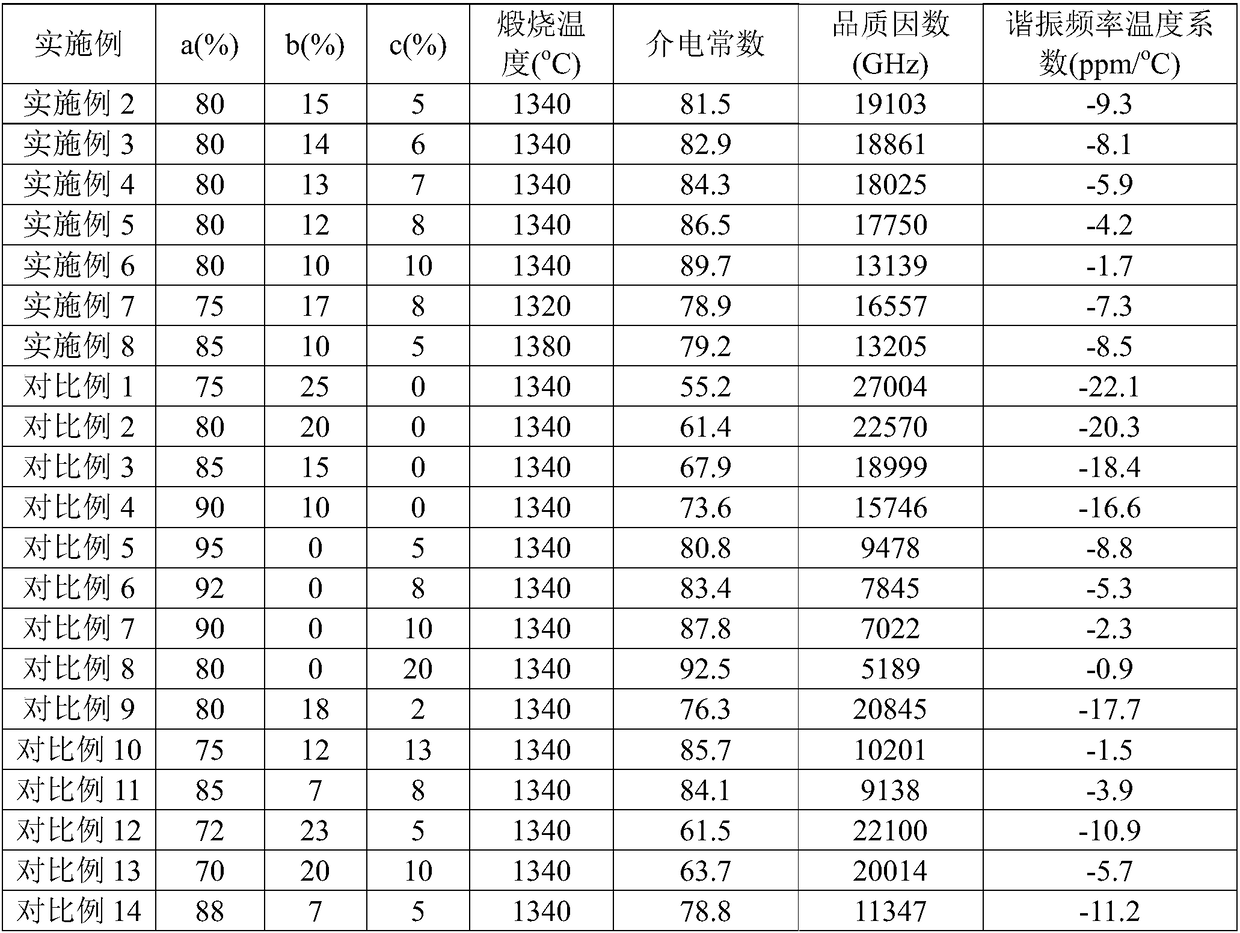

[0054] This embodiment provides a microwave dielectric ceramic, the structural formula of the microwave dielectric ceramic is: a(Ba 4 Sm 9.3 Ti 18 O 54 )-bMg 2 TiO 4 -cBi 2 O 3 , Where a=80%, b=15%, c=5%.

[0055] Prepare the microwave dielectric ceramics according to the following method:

[0056] (1) Put BaCO 3 , Sm 2 O 3 And TiO 2 Mix, fully ball mill after mixing, dry, sieved and put into corundum crucible after ball milling, then calcined at 1150℃ for 4h to obtain Ba 4 Sm 9.3 Ti 18 O 54 ;

[0057] (2) Combine MgO and TiO 2 Mix, fully ball mill after mixing, dry, sieving and put into corundum crucible after ball milling, then calcining at 1180℃ for 4h to obtain Mg 2 TiO 4 ;

[0058] (3) According to the formula amount, the Ba obtained in step (1) 4 Sm 9.3 Ti 18 O 54 , Mg obtained in step (2) 2 TiO 4 And Bi 2 O 3 After mixing, ball milling, drying, granulating, sieving after ball milling, the sieved particles are pressed into cylinders with a diameter of 10mm and a height of 6mm, an...

Embodiment 3

[0060] This embodiment provides a microwave dielectric ceramic, the structural formula of the microwave dielectric ceramic is: a(Ba 4 Sm 9.3 Ti 18 O 54 )-bMg 2 TiO 4 -cBi 2 O 3 , Where a=80%, b=14%, c=6%.

[0061] The microwave dielectric ceramics were prepared according to the method in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com