Solid rocket powder supersonic combustion ramjet engine

A solid rocket and scramjet technology, applied in the field of ramjets, can solve the problems of inability to realize active fuel flow adjustment, inconvenient maintenance and use, difficult fuel organization, etc., and achieve the effects of improving safety, reducing heat loss, and improving mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

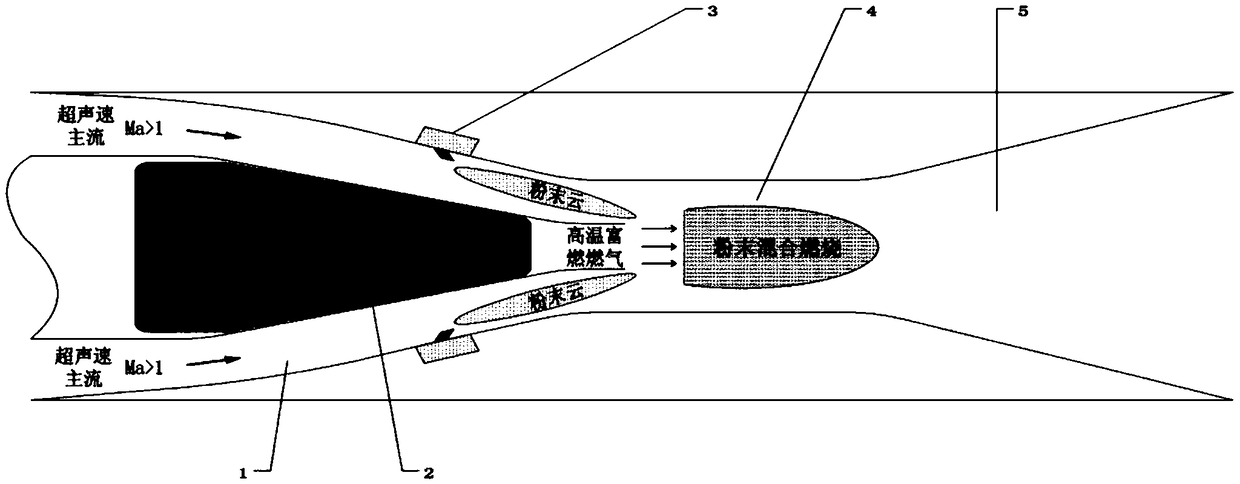

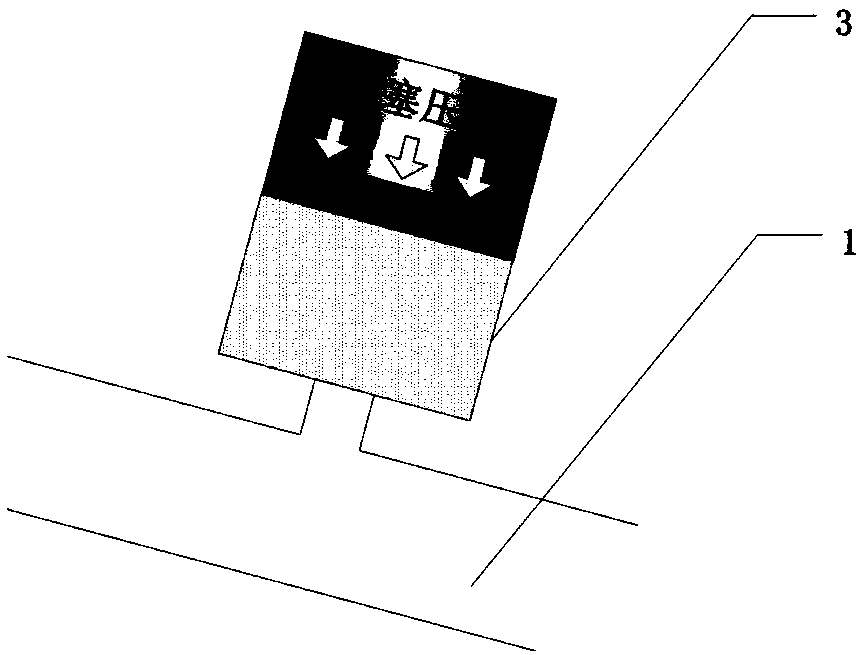

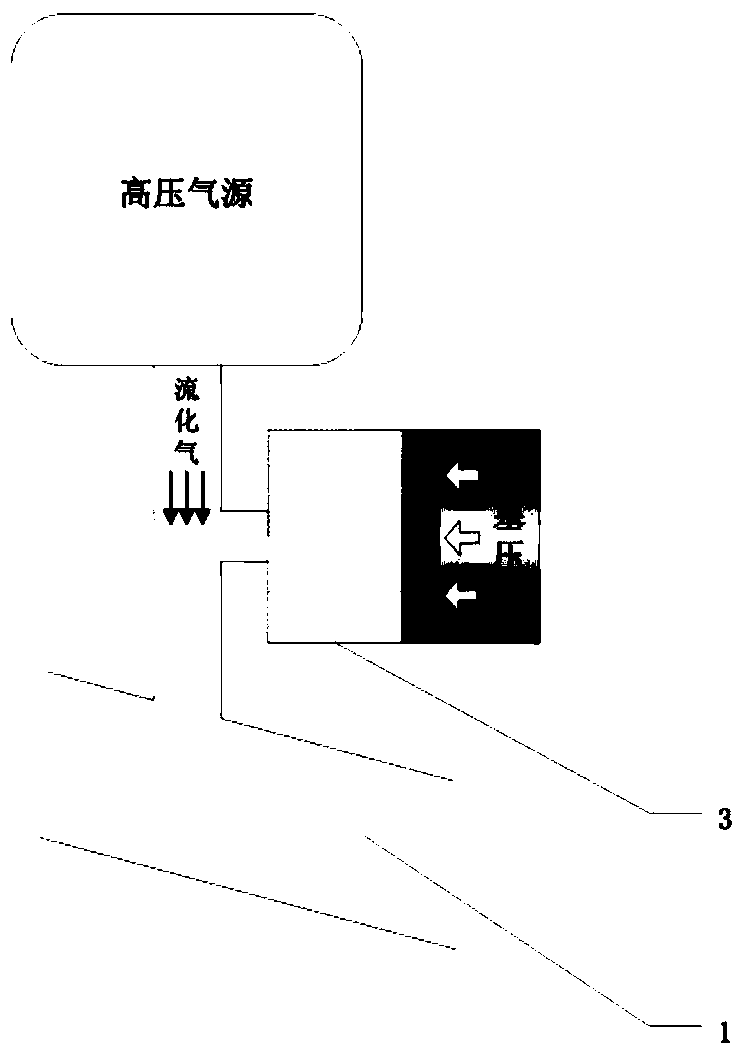

[0028] refer to figure 1 , 2 and 3, the present invention provides a solid rocket powder scramjet engine, comprising an air inlet 1, a gas generator 2, a powder supply system 3, a supersonic combustion chamber 4 and an exhaust nozzle 5. On the inner wall of the air inlet 1, there is a powder outlet for communicating with the powder supply system 3, and the powdered fuel output by the powder supply system 3 is pushed into the air inlet 1 through the powder outlet. The supersonic incoming air in the air inlet 1 entrains the powdered fuel ejected from the powder outlet, realizes the mixing of the powdered fuel and the supersonic incoming air and enters the supersonic combustion chamber 4 after mixing. The fuel burns in the gas generator 2 to generate high-temperature fuel-rich gas, which is sprayed into the supersonic combustion chamber 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com