Photochromic lens

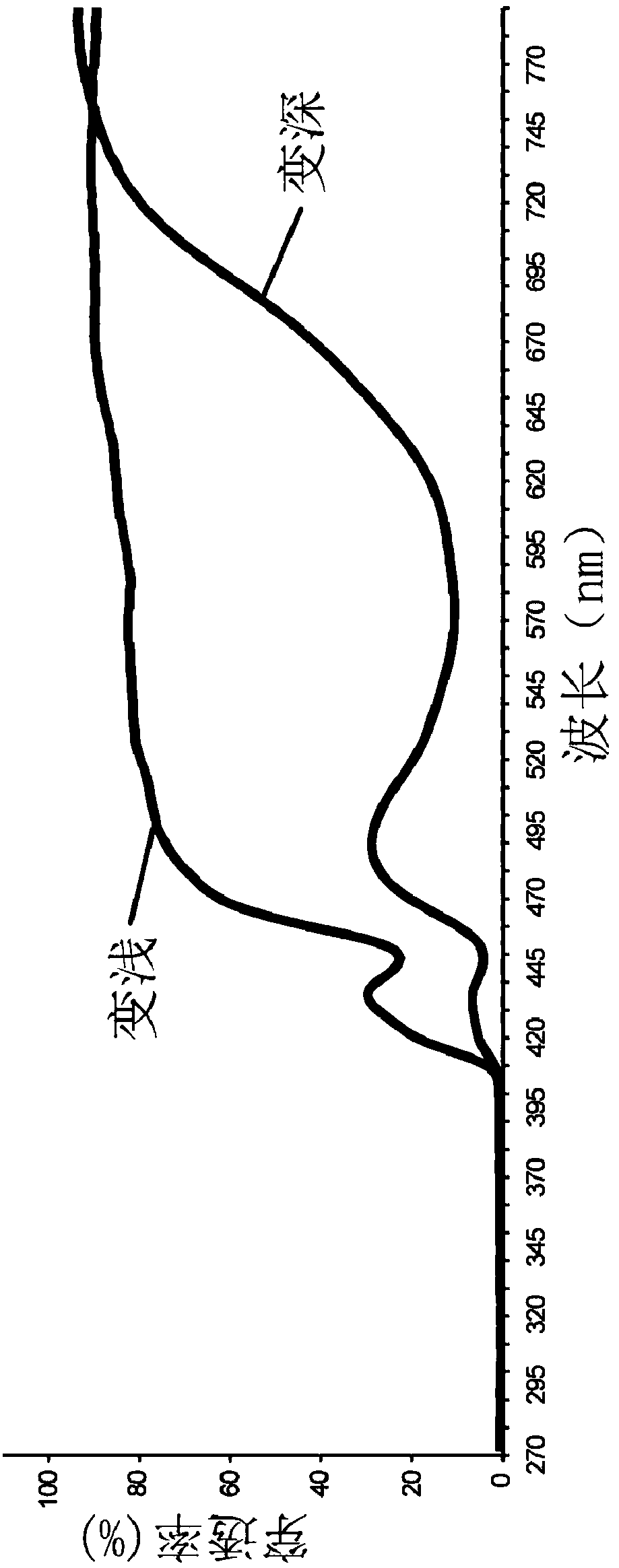

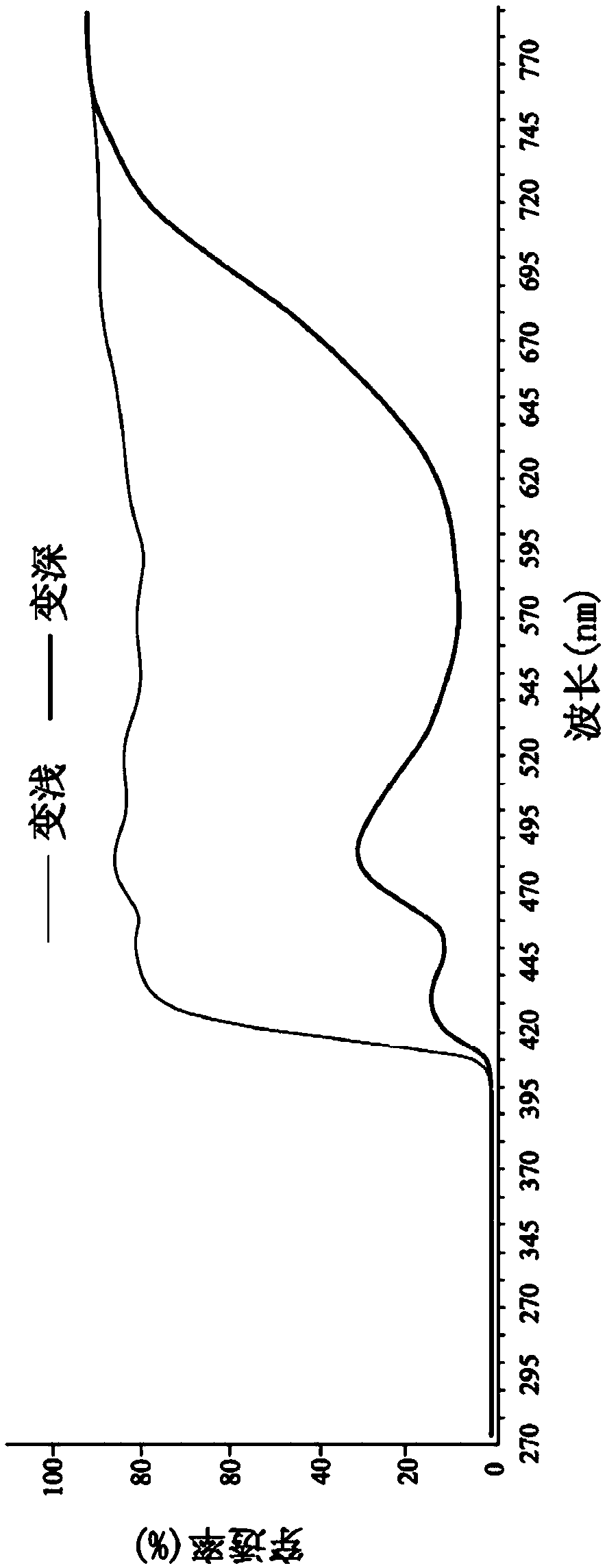

A color-changing lens and lens technology, applied in the field of color-changing lenses, can solve the problems of slow color-changing speed, reduced use safety, blurred vision, etc., and achieve the effect of fast color-changing speed and improved use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The color-changing lens in Example 1 is gray, and the color-changing liquid used in the color-changing film 2 is made of the following raw materials according to the ratio of parts by mass: 29 parts of blue toner 8410, 8 parts of green toner 8409, and 5 parts of red toner 8405 , 300 parts of toluene, 200 parts of polytetramethylene ether glycol, 150 parts of acrylic polymer, 7 parts of dimercapto sulfide, 100 parts of poly(methylene phenyl isocyanate), 200 parts of isocyanate compound, 1358 curing 80 parts of agent, 4 parts of 306 leveling agent, 4 parts of dibutyltin dilaurate, 10 parts of BASF light stabilizer 144, 5 parts of 1010 antioxidant, 10 parts of aluminum acetylacetonate.

Embodiment 2

[0026] The color-changing lens in Example 2 is brown, and the color-changing liquid used in the color-changing film 2 is made of the following raw materials according to the proportion by mass: 17 parts of blue toner 8410, 15 parts of green toner 8409, and 13 parts of red toner 8405 , 6 parts of yellow toner 8416, 280 parts of toluene, 130 parts of polytetramethylene ether glycol, 200 parts of acrylic polymer, 2 parts of dimercapto sulfide, 220 parts of poly(methylene phenyl isocyanate), 150 parts of isocyanate compound, 8 parts of 306 leveling agent, 4 parts of dibutyl tin dilaurate, 10 parts of BASF light stabilizer 144, 5 parts of 1010 antioxidant, 10 parts of aluminum acetylacetonate.

[0027] The above-mentioned blue toner 8410, green toner 8409, and red toner 8405 are products of Taiwan Chongyu Technology Co., Ltd. Kunshan Branch. 1358 curing agent and 306 leveling agent are agents of Guangzhou Baohua Trading Co., Ltd. German BYK Chemicals The company's products are all ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com