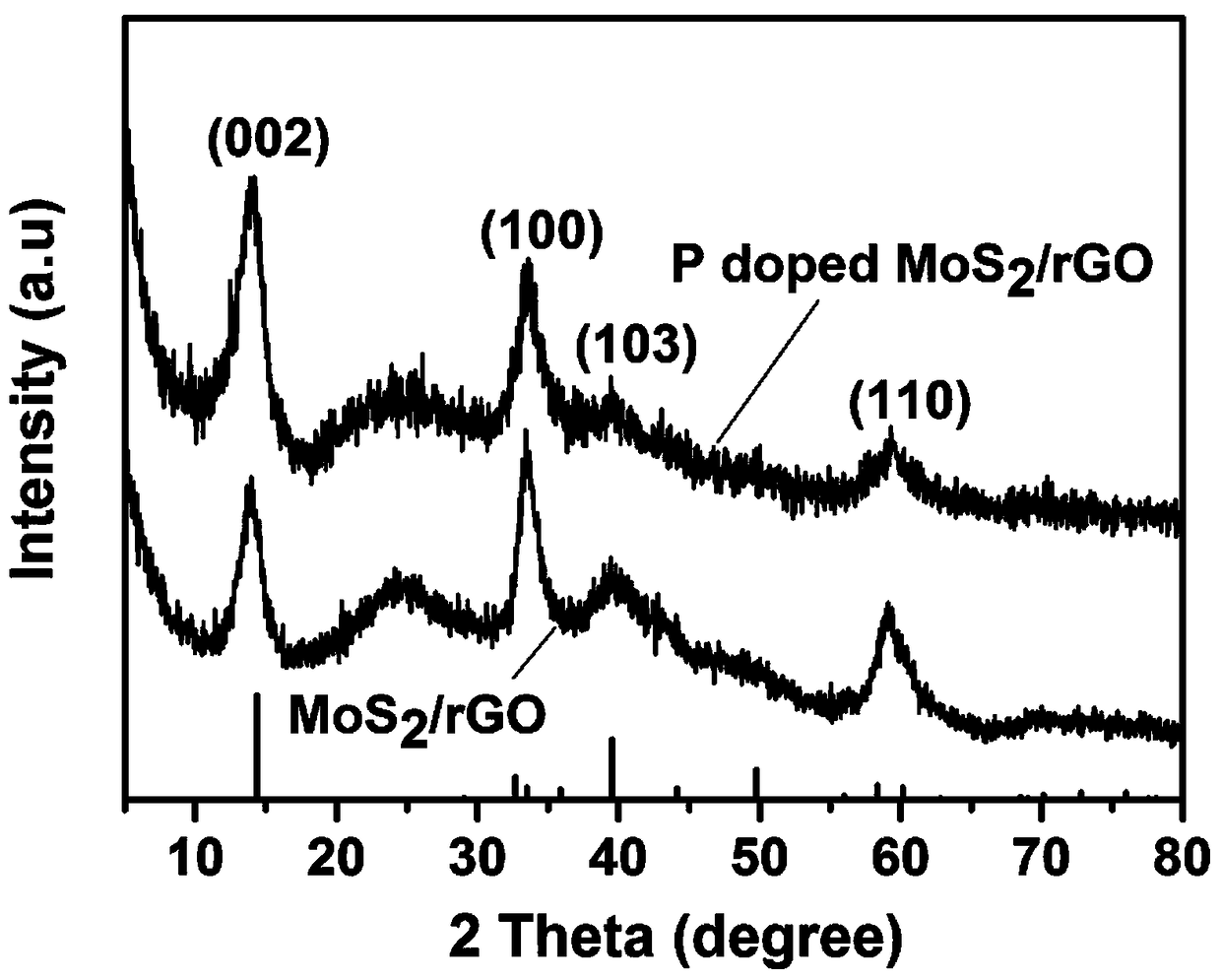

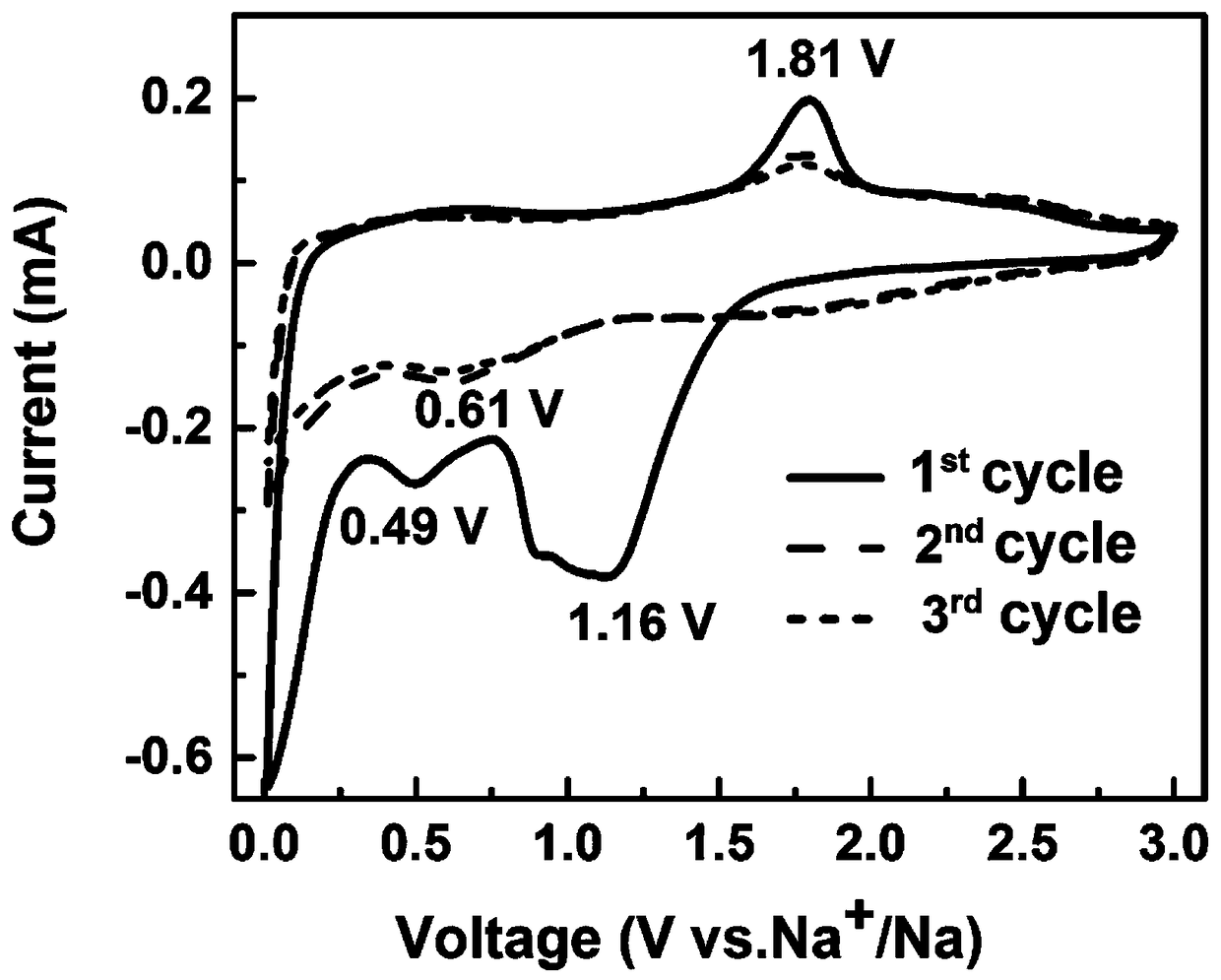

Preparation method and application of phosphorus-doped MoS2-loaded graphene nanosheet

A technology of graphene nanosheets and phosphorus doping, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of volume expansion, electrode material crushing, and poor electrochemical performance, so as to improve energy storage performance, Improvement of electronic conductivity and the effect of enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Phosphorus-doped MoS in this example 2 The preparation method of loaded graphene nanoplate, comprises the following steps:

[0032] 1. Preparation of graphene oxide: Add 70 mL of concentrated sulfuric acid with a mass concentration of 98% to a 500 mL three-necked flask and put it in an ice-water bath; weigh 2 g of flake graphite and add it to a three-necked flask containing concentrated sulfuric acid, and mechanically stir 20 min; Weigh 8 g of potassium permanganate and slowly add it to the above mixed solution. After stirring for 2 h under ice bath, transfer to a constant temperature water bath at 35°C and stir at a constant speed for 12 h (overnight) until the solution becomes viscous. yellowish brown; remove the three-neck flask from the water bath, slowly add 297 mL of deionized water dropwise and keep stirring until it cools down to room temperature; measure 25 mL of 30% H 2 o 2 Added to the above solution, washed three times with dilute hydrochloric acid and dei...

Embodiment 2

[0036] Phosphorus-doped MoS in this example 2 The preparation method of loaded graphene nanoplate, comprises the following steps:

[0037]1. Preparation of graphene oxide: Add 70 mL of concentrated sulfuric acid with a mass concentration of 98% to a 500 mL three-necked flask and put it in an ice-water bath; weigh 2 g of flake graphite and add it to a three-necked flask containing concentrated sulfuric acid, and mechanically stir 25 min; Weigh 8 g of potassium permanganate and slowly add it to the above mixed solution. After stirring for 2 h under ice bath, transfer to a constant temperature water bath at 35°C and stir at a constant speed for 12 h (overnight) until the solution becomes viscous. yellowish brown; remove the three-neck flask from the water bath, slowly add 297 mL of deionized water dropwise and keep stirring until it cools down to room temperature; measure 25 mL of 30% H 2 o 2 Added to the above solution, washed three times with dilute hydrochloric acid and deio...

Embodiment 3

[0041] Phosphorus-doped MoS in this example 2 The preparation method of loaded graphene nanoplate, comprises the following steps:

[0042] 1. Preparation of graphene oxide: Add 70 mL of concentrated sulfuric acid with a mass concentration of 98% to a 500 mL three-necked flask and put it in an ice-water bath; weigh 2 g of flake graphite and add it to a three-necked flask containing concentrated sulfuric acid, and mechanically stir 30 min; Weigh 8 g of potassium permanganate and slowly add it to the above mixed solution. After stirring for 2 h under ice bath, transfer to a 35°C constant temperature water bath and stir at a constant speed for 12 h (overnight) until the solution becomes viscous. yellowish brown; remove the three-neck flask from the water bath, slowly add 297 mL of deionized water dropwise and keep stirring until it cools down to room temperature; measure 25 mL of 30% H 2 o 2 Added to the above solution, washed three times with dilute hydrochloric acid and deioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com