Copper nanowire and preparation method thereof

A technology of copper nanowires and copper alloys, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. problem, to achieve the effect of simple and feasible preparation method, good affinity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

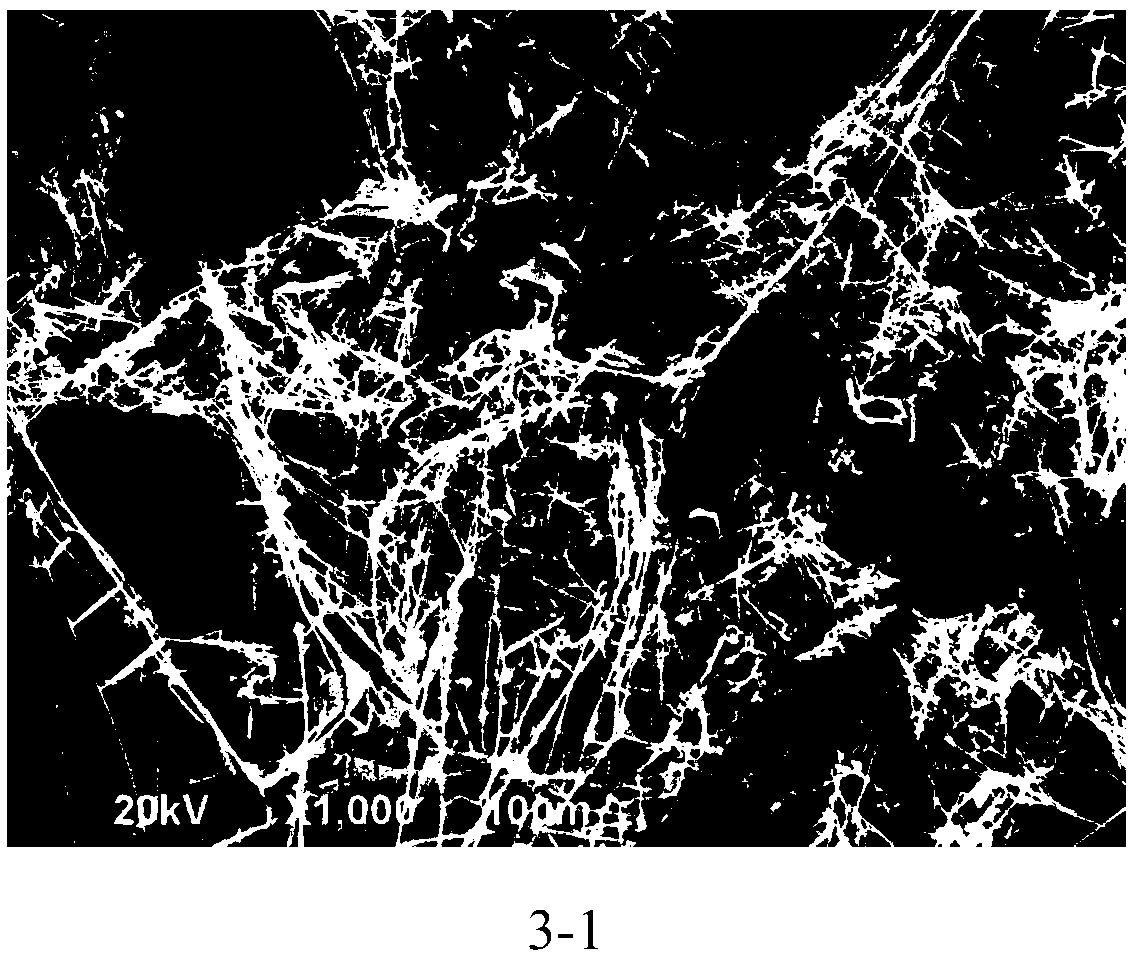

[0033] A kind of copper nano wire, its preparation method comprises the following steps:

[0034] (1) In an environment with a dew point of -50°C and an oxygen content of 10ppm, the lithium metal is heated to 200°C, and the lithium metal is in a molten state at this time;

[0035] (2) Metal copper is added in the metallic lithium of molten state, heat preservation 10min, mix, form the alloy of melting; Wherein, the atomic number ratio of copper and metallic lithium is 1:100;

[0036] (3) cooling the molten alloy to room temperature within 5min to obtain lithium-copper alloy CuLi100;

[0037] (4) Lithium-copper alloy CuLi100 is put into water, and metal lithium is removed through redox reaction of lithium and water to obtain copper nanowires.

Embodiment 2

[0039] A kind of copper nano wire, its preparation method comprises the following steps:

[0040] (1) In an environment with a dew point of -60°C and an oxygen content of 2ppm, the metal lithium is heated to 200°C, and the metal lithium is in a molten state at this time;

[0041] (2) Metal copper is added in the metallic lithium of molten state, heat preservation 10min, mix, form the molten alloy; Wherein, the atomic number ratio of copper and metallic lithium is 1:60;

[0042] (3) cooling the molten alloy to room temperature within 5min to obtain lithium-copper alloy CuLi60;

[0043] (4) Lithium-copper alloy CuLi60 is put into water, and metal lithium is removed through redox reaction of lithium and water to obtain copper nanowires.

Embodiment 3

[0045] A kind of copper nano wire, its preparation method comprises the following steps:

[0046] (1) In an environment with a dew point of -70°C and an oxygen content of 1ppm, the lithium metal is heated to 800°C, and the lithium metal is in a molten state at this time;

[0047] (2) Metal copper is added in the metallic lithium of molten state, heat preservation 10min, mix, form the molten alloy; Wherein, the atomic number ratio of copper and metallic lithium is 2:3;

[0048] (3) cooling the molten alloy to room temperature within 5min to obtain lithium-copper alloy Cu2Li3;

[0049] (4) Lithium-copper alloy Cu2Li3 is put into water, and metal lithium is removed through redox reaction of lithium and water to obtain copper nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com