Method for making high-purity refined sulfuric acid

A manufacturing method and high-purity technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of insignificant cost advantages and high energy consumption, and achieve the protection of downstream equipment, low production energy consumption, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

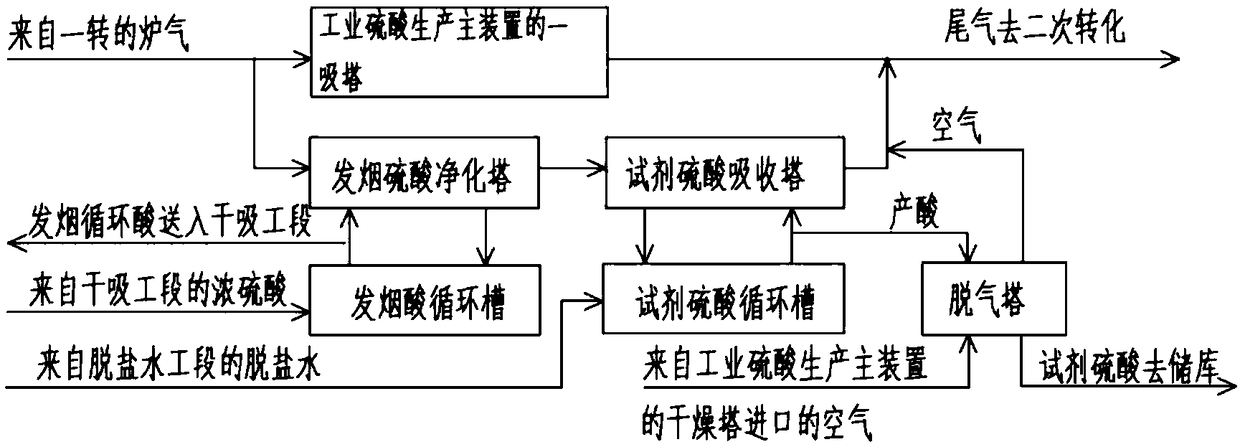

[0031] See figure 1 . A kind of manufacture method of high-purity refined sulfuric acid of present embodiment, it may further comprise the steps:

[0032] Step 1, equipment transformation: build a fuming sulfuric acid purification tower and a reagent sulfuric acid absorption tower, and set a bypass at the inlet of the first suction tower of the industrial sulfuric acid production main device to connect with the fuming sulfuric acid purification tower, and absorb the reagent sulfuric acid The tail gas of the tower is connected back to the outlet of the first suction tower of the main unit of industrial sulfuric acid production;

[0033] Step 2, nicotin acid cycle pickling purification process: the SO4 sent by the industrial sulfuric acid production main device is transformed 3 Furnace gas, and enter from the bottom of the fuming sulfuric acid purification tower, and then SO 3 The furnace gas and the fuming circulating acid entering the upper part of the fuming sulfuric acid ...

Embodiment 2

[0037] See figure 1 . A kind of manufacture method of high-purity refined sulfuric acid of present embodiment, it may further comprise the steps:

[0038] Step 1, equipment transformation: build a fuming sulfuric acid purification tower and a reagent sulfuric acid absorption tower, and set a bypass at the inlet of the first suction tower of the industrial sulfuric acid production main device to connect with the fuming sulfuric acid purification tower, and absorb the reagent sulfuric acid The tail gas of the tower is connected back to the outlet of the first suction tower of the main unit of industrial sulfuric acid production;

[0039] Step 2, nicotin acid cycle pickling purification process: the SO4 sent by the industrial sulfuric acid production main device is transformed 3 Furnace gas, and enter from the bottom of the fuming sulfuric acid purification tower, and then SO 3 The furnace gas and the fuming circulating acid entering the upper part of the fuming sulfuric acid ...

Embodiment 3

[0043] See figure 1 . A kind of manufacture method of high-purity refined sulfuric acid of present embodiment, it may further comprise the steps:

[0044] Step 1, equipment transformation: build a fuming sulfuric acid purification tower and a reagent sulfuric acid absorption tower, and set a bypass at the inlet of the first suction tower of the industrial sulfuric acid production main device to connect with the fuming sulfuric acid purification tower, and absorb the reagent sulfuric acid The tail gas of the tower is connected back to the outlet of the first suction tower of the main unit of industrial sulfuric acid production;

[0045] Step 2, nicotin acid cycle pickling purification process: the SO4 sent by the industrial sulfuric acid production main device is transformed 3 Furnace gas, and enter from the bottom of the fuming sulfuric acid purification tower, and then SO 3 The furnace gas and the fuming circulating acid entering the upper part of the fuming sulfuric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com