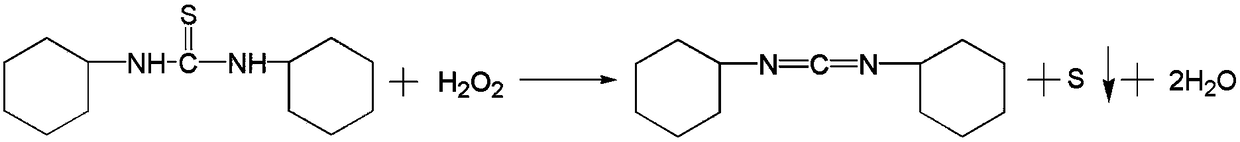

Method for synthesizing N, N'-dicyclohexylcarbodiimide through hydrogen peroxide serving as oxidizing agent

A technology of dicyclohexylcarbodiimide and hydrogen peroxide, which is applied in the direction of organic chemistry, can solve the problems of high hidden dangers, highly toxic phosgene, and difficult to apply to workshop production, so as to improve utilization rate, reduce environmental protection investment, waste The effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix N,N'-dicyclohexylthiourea and solvent toluene at a mass ratio of 1.9:1, then slowly add the catalyst triethylamine under stirring conditions, the amount of triethylamine is 5% of the total material mass, at 20°C Add hydrogen peroxide dropwise for oxidation reaction, the mass ratio of hydrogen peroxide to N,N′-dicyclohexylthiourea is 1.15:1, keep warm for 1.5h after the dropwise addition, then filter with suction at 15°C, decolorize, and distill under reduced pressure N,N'-dicyclohexylcarbodiimide was obtained with a yield of 93.9% and a purity of 99.34%. The waste water produced by oxidation passed the test after MVR distillation and was used as cooling circulating water.

Embodiment 2

[0023] Mix N,N'-dicyclohexylthiourea and solvent toluene at a mass ratio of 1.6:1, then slowly add the catalyst triethylamine under stirring conditions, the amount of triethylamine is 4% of the total material mass, at 25°C Add hydrogen peroxide dropwise for oxidation reaction, the mass ratio of hydrogen peroxide to N,N′-dicyclohexylthiourea is 1:1, keep warm for 1.5h after the dropwise addition, then filter with suction at 15°C, decolorize and distill under reduced pressure N,N'-dicyclohexylcarbodiimide was obtained with a yield of 93.6% and a purity of 99.35%. The waste water produced by oxidation passed the test after MVR distillation and was used as cooling circulating water.

Embodiment 3

[0025] Mix N,N'-dicyclohexylthiourea and solvent toluene at a mass ratio of 1.8:1, then slowly add the catalyst triethylamine under stirring conditions, the amount of triethylamine is 6% of the total material mass, at 15°C Add hydrogen peroxide dropwise for oxidation reaction, the mass ratio of hydrogen peroxide to N,N′-dicyclohexylthiourea is 1.2:1, keep warm for 1.5h after the dropwise addition, then suction filter at 15°C, decolorize, and distill under reduced pressure N,N'-dicyclohexylcarbodiimide was obtained with a yield of 93.7% and a purity of 99.37%. The waste water produced by oxidation passed the test after MVR distillation and was used as cooling circulating water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com