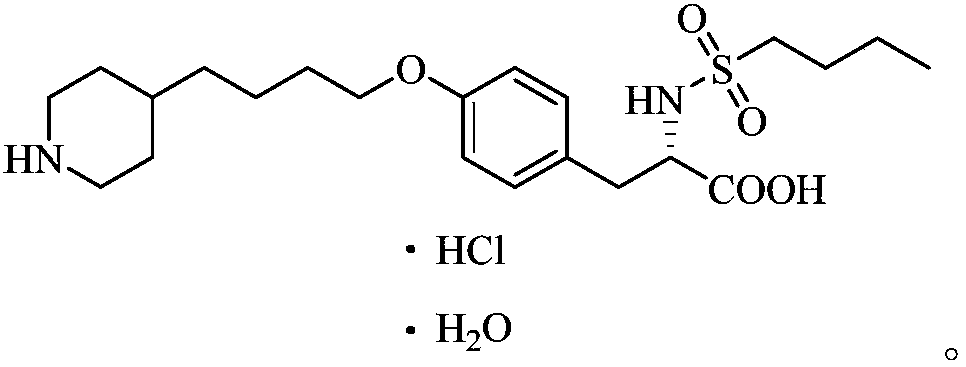

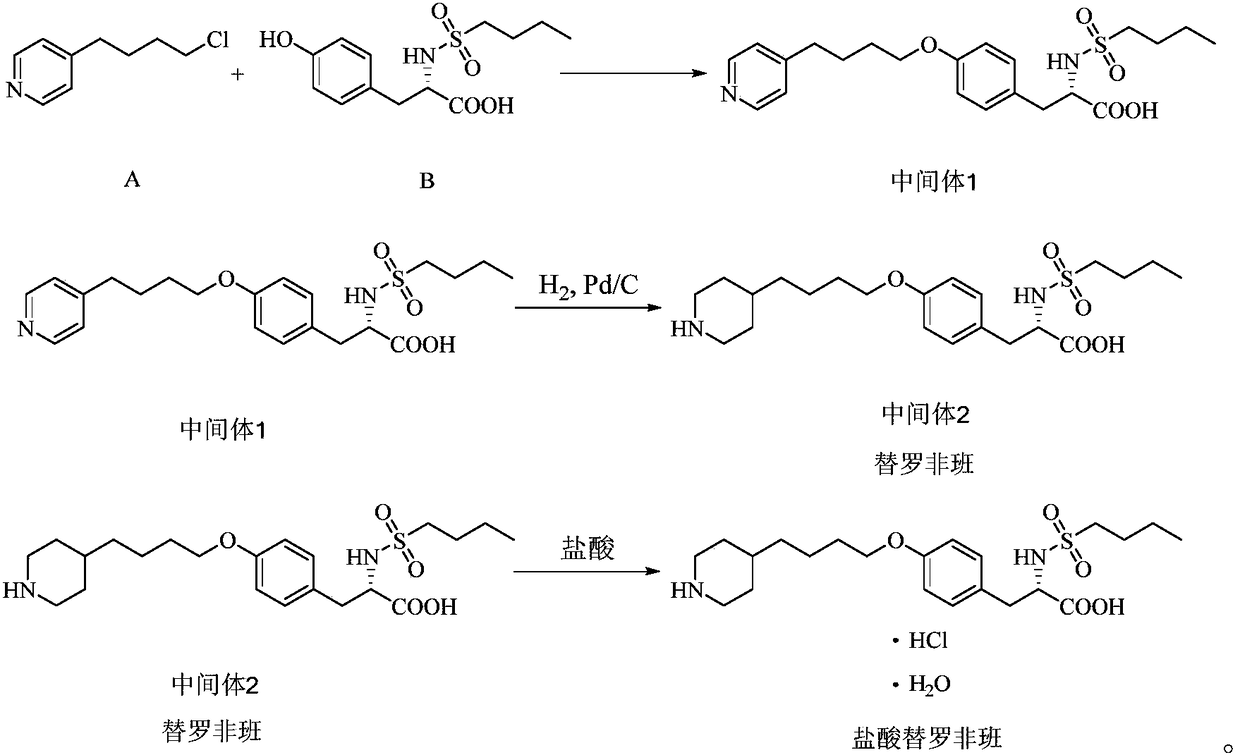

Palladium removal method for preparation process of tirofiban hydrochloride

A technology of tirofiban and a preparation process is applied in the field of palladium removal of the preparation process of tirofiban hydrochloride, can solve the problems such as no method for removing palladium, excessive metal palladium content, etc., and achieves remarkable effect, simple operation, and reduced Effect of palladium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment shows the first specific implementation of the palladium removal method of a tirofiban hydrochloride preparation process, which includes the following steps:

[0032] Put 20g of tirofiban hydrochloride into 400ml of methanol solution, which contains 0.001g / ml of triphenylphosphine, keep the temperature at 20°C for 24 hours in a water bath and then filter under reduced pressure, and filter the obtained filter cake with 40ml of methanol After rinsing, it was air-dried at 40°C to obtain 19.55 g of a white solid with a palladium content of 0.7 ppm.

[0033] In the present embodiment, the method for detecting the palladium content of tirofiban hydrochloride is:

[0034] (1) Instruments and reagents

[0035] Instrument: Thermo-Scientific ICE 3500 atomic absorption spectrometer; SOLAAR data workstation V11.03.

[0036] Reagent: palladium standard solution; nitric acid; water is purified water;

[0037] (2) Spectral parameters and atomization conditions

[0...

Embodiment 2

[0053] Put 20 g of tirofiban hydrochloride into 200 ml of ethanol solution of 0.001 g / ml p-methyltriphenylphosphine, keep the temperature at 25° C. in a water bath and stir for 10 h, then filter under reduced pressure, wash the obtained filter cake with 40 ml of methanol, and wash with Air-dried at 40°C to obtain 19.67 g of a white solid with a palladium content of 0.9 ppm.

[0054] For the technical solutions of the same parts in this embodiment and the first embodiment, please refer to the description in the first embodiment, and will not be repeated here.

Embodiment 3

[0056] Put 20g of tirofiban hydrochloride into 600ml of acetonitrile solution of 0.001g / ml tri-n-butylphosphine, keep the temperature at 40°C and stir in a water bath for 30h, then filter under reduced pressure, wash the obtained filter cake with 30ml of methanol, and wash it at 40°C Blast drying gave 19.32 g of a white solid with a palladium content of 0.7 ppm.

[0057] For the technical solutions of the same parts in this embodiment and Embodiment 1 or Embodiment 2, refer to the description in Embodiment 1 or Embodiment 2, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com