Method for preparing pneumococcal capsular polysaccharide by viscosity control

A technology for pneumococcus and capsular polysaccharide is applied in the field of preparation of pneumococcal capsular polysaccharide, which can solve the problems of increasing downstream process pressure, excessive dilution, affecting stirring effect, etc., and achieves good quality, improved production efficiency and recovery rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

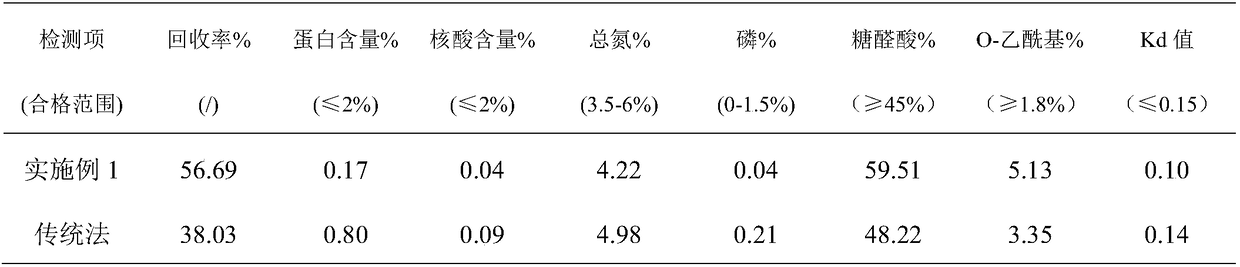

Embodiment 1、1

[0091] The viscosity control of embodiment 1, type 1 pneumococcal polysaccharide solution ultrafiltration

[0092] (a) Type 1 pneumococcus fermentation broth is inactivated, centrifuged, clarified and filtered, and then concentrated until the viscosity reaches 10 cp, and then dialyzed. After dialysis, continue to over-concentrate the solution, wash the membrane bag 2-3 times with buffer solution, collect the concentrated solution, and stir evenly.

[0093] (b) Detect the viscosity of the type 1 polysaccharide solution, dilute the solution viscosity with buffer solution to 10cp for clarification and filtration, continue to dilute with buffer solution to a viscosity of 5cp after filtration, and add CTAB solution under continuous stirring.

[0094] (c) Centrifuge the CTAB polysaccharide solution, collect the precipitate, place in the sodium chloride solution and continue to stir, add the sodium chloride solution until the viscosity increases to 5cp until the viscosity is 3cp; add...

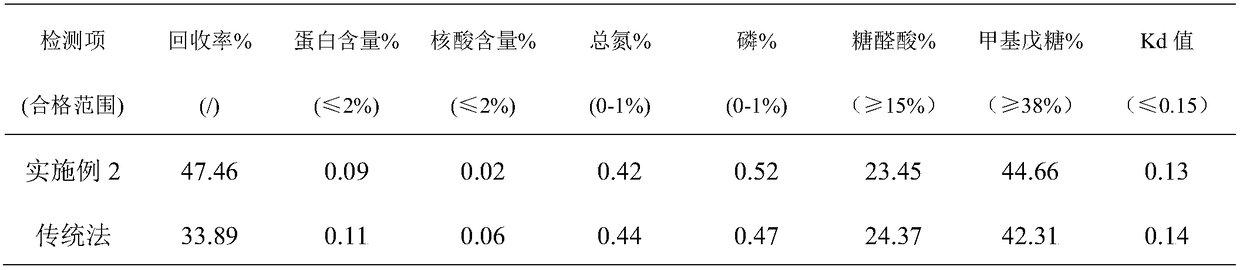

Embodiment 2

[0102] The viscosity control of embodiment 2, type 2 pneumococcal polysaccharide solution ultrafiltration

[0103] (a) After inactivation, centrifugation, clarification and filtration of the type 2 pneumococcal fermentation liquid, it is concentrated first, and when the viscosity reaches 8cp, dialysis is started. After dialysis, continue to over-concentrate the solution, wash the membrane bag 2-3 times with buffer solution, collect the concentrated solution, and stir evenly.

[0104] (b) Detect the viscosity of the type 2 polysaccharide solution, dilute the solution viscosity with buffer solution to 8cp for clarification and filtration, continue to dilute with buffer solution to a viscosity of 3cp after filtration, and add CTAB solution in a state of continuous stirring.

[0105] (c) Centrifuge the CTAB polysaccharide solution, collect the precipitate, place in the sodium chloride solution and continue to stir, add the sodium chloride solution until the viscosity increases to ...

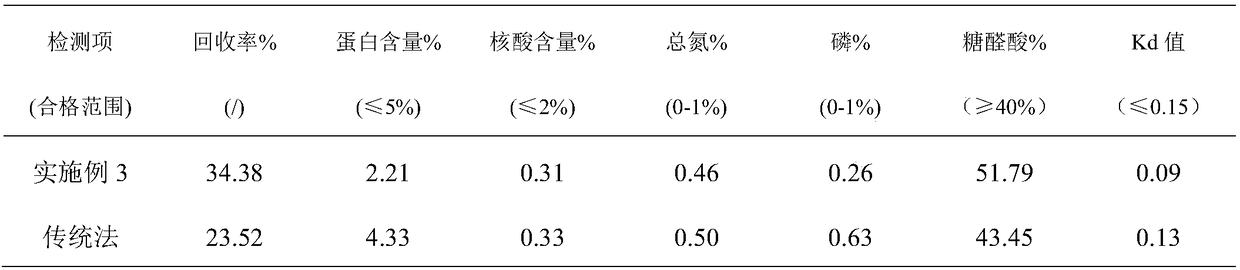

Embodiment 3

[0113] The viscosity control of embodiment 3, type 3 pneumococcal polysaccharide solution ultrafiltration

[0114] (a) Type 3 pneumococcus fermentation broth is inactivated, centrifuged, clarified and filtered, and then concentrated, until the viscosity reaches 10cp, and then dialyzed. After dialysis, continue to over-concentrate the solution, wash the membrane bag 2-3 times with buffer solution, collect the concentrated solution, and stir evenly.

[0115] (b) Detect the viscosity of the type 3 polysaccharide solution, use buffer to dilute the solution viscosity to 10cp for clarification and filtration, use buffer to continue diluting to a viscosity of 5cp after filtration, and add CTAB solution in a state of continuous stirring.

[0116] (c) Centrifuge the CTAB polysaccharide solution, collect the precipitate, place in the sodium chloride solution and continue to stir, add the sodium chloride solution until the viscosity increases to 5cp until the viscosity is 3cp; add the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com