Preparation method of cell wall with high glucan content

A cell wall and glucan technology, applied in the field of high-sugar cell wall products, can solve the problem of low utilization rate of yeast cell wall, and achieve the effect of cost-effective and reduced enzyme amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

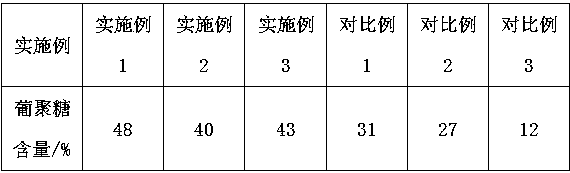

Examples

Embodiment 1

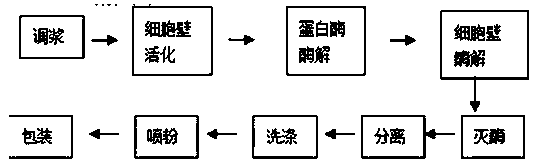

[0024] The specific process is:

[0025] (1) Slurry: recycle the waste material after yeast extraction to make a slurry with a cell wall content of 10wt%;

[0026] (2) Cell wall activation: add NaOH solution to the cell wall slurry to adjust the pH to 8, use a reactor to heat up to 120°C, and keep warm for 4 hours;

[0027] (3) Protease hydrolysis: cool the activated cell wall slurry to 60°C, adjust the pH to 7.5, add 4.5‰ of cell wall dry matter alkaline protease, and act for 8 hours;

[0028] (4) Cell wall enzymatic hydrolysis: lower the temperature to 48°C, adjust the pH to 5, add 2wt‰ plant hydrolase to the dry matter of the cell wall, and act for 7 hours;

[0029] (5) Enzyme inactivation: heat up to 90°C, keep warm for 60 minutes, then cool down to 65°C; Separation: Use a high-speed disc centrifuge at 5000r / min, centrifuge, and take the heavy phase;

[0030] (6) Washing: wash the separated heavy phase twice, the ratio of material to water is 1:1;

[0031] (7) Powder sp...

Embodiment 2

[0034] (1) Slurry: recycle the waste material after yeast extraction to make a slurry with a cell wall content of 8wt%;

[0035] (2) Cell wall activation: add NaOH solution to the cell wall slurry to adjust the pH to 7.5, use a reactor to heat up to 125°C, and keep warm for 4 hours;

[0036] (3) Protease enzymatic hydrolysis: cool the activated cell wall slurry to 65°C, adjust the pH to 7, add 4‰ alkaline protease of the dry matter mass of the cell wall, and act for 8 hours;

[0037] (4) Cell wall enzymatic hydrolysis: lower the temperature by 50°C, adjust the pH to 5.5, add 1.8‰ of cell wall dry matter plant hydrolase, and act for 8 hours;

[0038] (5) Enzyme inactivation: heat up to 85°C, keep warm for 60 minutes, then cool down to 65°C; Separation: Use a high-speed disc centrifuge at 5000r / min, centrifuge, and take the heavy phase;

[0039] (6) Washing: wash the separated heavy phase twice, the ratio of material to water is 1:1;

[0040] (7) Powder spraying: adjust the so...

Embodiment 3

[0043] (1) Slurry: recycle the waste material after yeast extraction to make a slurry with a cell wall content of 12wt%;

[0044] (2) Cell wall activation: add NaOH solution to the cell wall slurry to adjust the pH to 8.5, use a reactor to heat up to 110°C, and keep warm for 2 hours;

[0045] (3) Protease enzymatic hydrolysis: cool the activated cell wall slurry to 65°C, adjust the pH to 8, add 3‰ of the cell wall dry matter alkaline protease, and act for 10 hours;

[0046] (4) Cell wall enzymatic hydrolysis: lower the temperature to 45°C, adjust the pH to 4.5, add 1.8‰ of cell wall dry matter plant hydrolase, and act for 7 hours;

[0047] (5) Enzyme inactivation: heat up to 85°C, keep warm for 30 minutes, and cool down to 60°C; Separation: Use a high-speed disc centrifuge at 5000r / min, centrifuge, and take the heavy phase;

[0048] (6) Washing: wash the separated heavy phase twice, the ratio of material to water is 1:1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com