Collagen-based self-healing hydrogel and preparation method thereof

A self-healing and hydrogel technology, applied in the field of collagen materials, can solve the problems of non-self-healing, difficult to self-repair, shorten the life of hydrogel implants, etc., to achieve a good cell living environment, good toughness and self-healing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

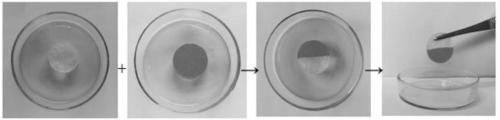

Image

Examples

preparation example Construction

[0030] A preparation method of collagen-based self-repairing hydrogel, which comprises the following specific steps:

[0031] (1) Dissolve collagen in an acetic acid solution with a concentration of 0.01-0.1 mol / L, and then stir evenly to prepare a collagen solution with a mass concentration of 10-30 mg / mL;

[0032] (2) Pipette guar gum and dialdehyde guar gum at a ratio of 0.5 to 4:1 by mass ratio and dissolve them in deionized water at the same time, and then dissolve them in deionized water at 30 to 80 Stirring and mixing for 2 to 6 hours under the temperature condition of ℃ to prepare a guar gum / dialdehyde guar gum compound solution with a total mass concentration of 10 to 30 mg / mL;

[0033] (3) Dissolving borax in PBS buffer solution to prepare a borax solution with a mass concentration of 0.05-0.2 mol / L;

[0034] (4) Blend the collagen solution prepared in step (1) with equal mass concentration and the guar gum / dialdehyde guar gum compound solution prepared in step (2) ...

Embodiment 1

[0044] (1) Dissolve 5 g of guar gum in 50 mL of ethanol, add 40 mL of NaIO with a concentration of 0.1 mol / L 4 solution, and react in the dark at room temperature for 12 h; after the oxidation reaction is completed, add 0.5 mL ethylene glycol solution to the mixed solution to terminate the reaction, and stir at room temperature for 0.5 h; wash the reaction product 3 times with tert-butanol, wash After cleaning, it was subjected to vacuum freezing treatment for 12 h, and then the processed product was ground to obtain powdered formylated guar gum with a degree of formylation of 4%.

[0045] (2) Cut the cowhide into small pieces, put it into a meat grinder and grind it, then put the ground cowhide with a wet weight of about 10g into a 1 L Erlenmeyer flask, and add pepsin equivalent to 3% of the wet weight of the cowhide and 500 mL of acetic acid with a concentration of 0.1 mol / L, and then put it into a constant temperature shaker at 4 ℃ for vibration extraction at a speed of 180...

Embodiment 2

[0051] (1) Dissolve 10 g of guar gum in 50 mL of ethanol, add 40 mL of 0.5 mol / L NaIO 4 solution, and reacted in the dark at room temperature for 24 h; after the oxidation reaction was completed, 2 mL of ethylene glycol solution was added to the product to terminate the reaction, and stirred at room temperature for 2 h; the reaction product was washed with tert-butanol for 5 times, and the Carry out vacuum freezing treatment for 24 h, then grind the product obtained after the treatment to obtain powdered formylated guar gum, and its degree of formylation is 8%;

[0052] (2) Cut the cowhide into small pieces, put it into a meat grinder and grind it, put the ground cowhide with a wet weight of about 10 g into a 1 L Erlenmeyer flask, add pepsin equivalent to 3% of the wet weight of the cowhide and 500 mL of acetic acid with a concentration of 0.5 mol / L, and then put it into a constant temperature shaker at 4 ℃ for vibration extraction at a speed of 180 r / min for 72 h. The soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com