Aqueous mirror back aluminum plated protective coating

A technology for protecting coatings and mirror backs, applied in the direction of anti-corrosion coatings, coatings, etc., to achieve the effect of approaching the overall use cost, avoiding secondary environmental pollution, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

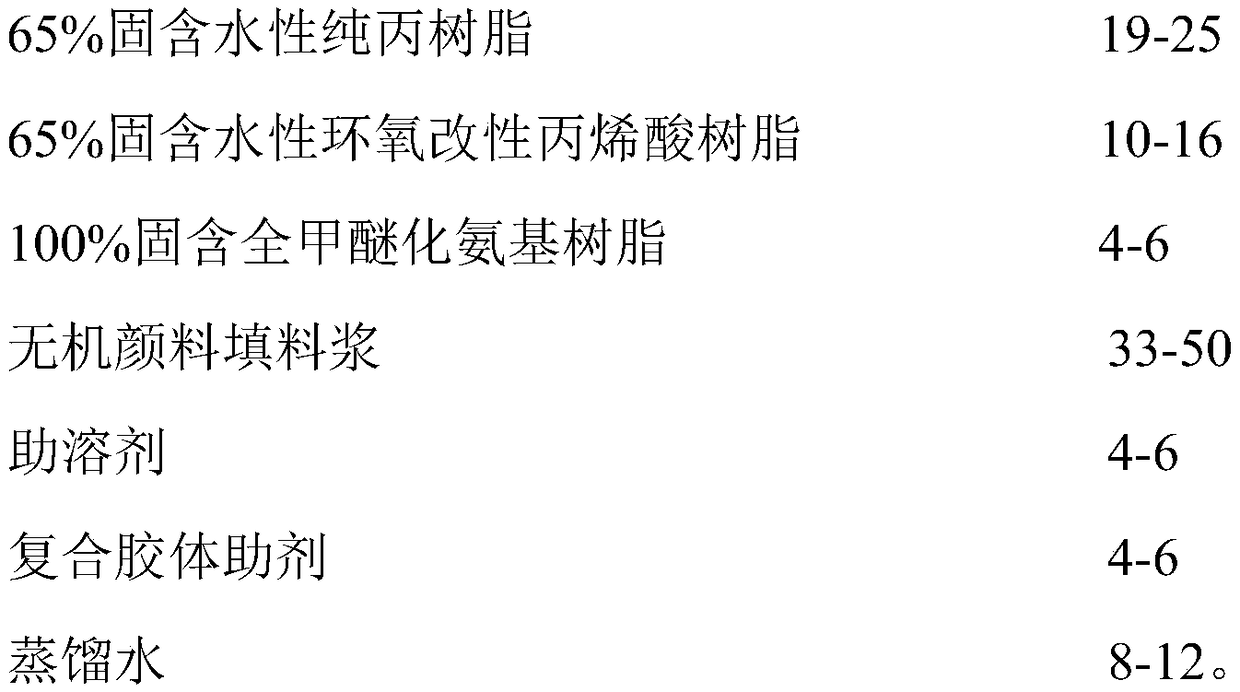

[0030] The invention provides a kind of water-based mirror back aluminized protective coating, and by weight percentage, described coating comprises following raw material:

[0031]

[0032] The preparation method step of described 65% solid water-based pure acrylic resin is:

[0033] (1) The mixture acrylic acid monomer is pumped into the reaction vessel with a feeding pump, and the pumping time is 25-30min;

[0034] (2) The first type of initiator dissolved in solvent is added dropwise in the reaction vessel of step (1), and stirred, while insulated at 80-85°C for 1.5-3.5h, the first type of initiator is Organic peroxides, such as one or more of dibenzoyl peroxide, tert-butyl monoperoxyphthalate, tert-butyl peroxyacetate and tert-amyl peroxybenzoate, etc., the solvent It can be one or more of ethylene glycol butyl ether, butanol, diethylene glycol butyl ether, propylene glycol butyl ether, dipropylene glycol butyl ether, propylene glycol methyl ether, isopropanol, and et...

Embodiment 2

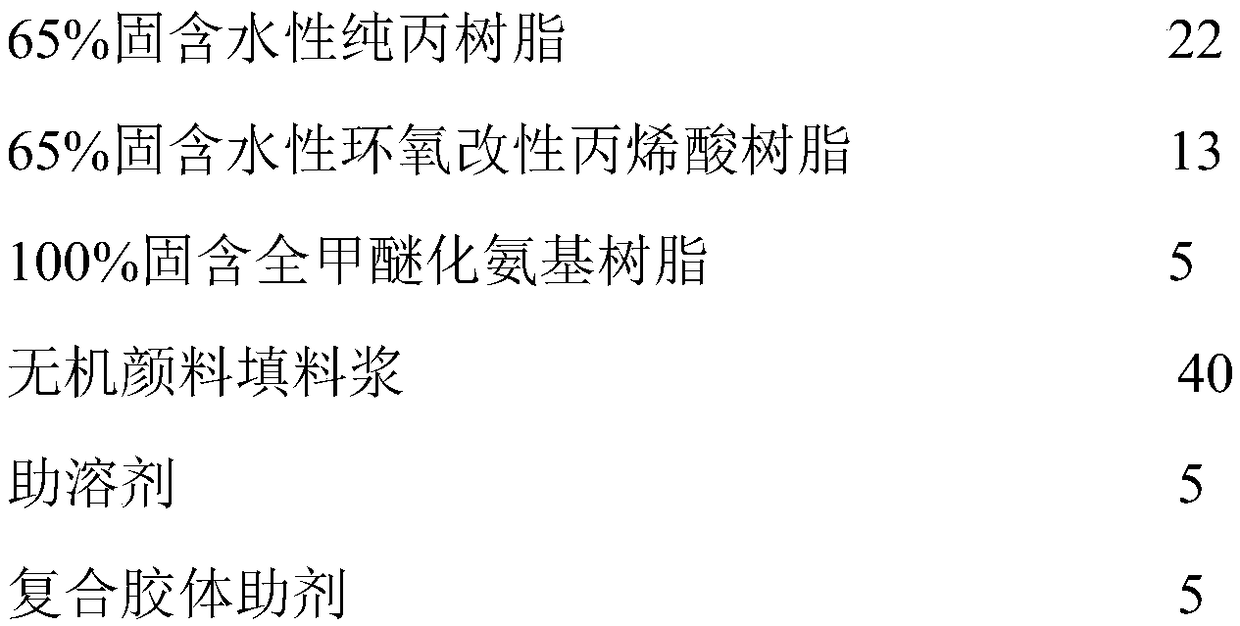

[0053] On the basis of embodiment 1, present embodiment 2 is as a preferred embodiment of the present invention, a kind of water-based mirror back aluminized protective coating, by weight percentage, comprises following raw material:

[0054]

[0055]

[0056] Wherein, the pumping time in the described preparation step (1) of the 65% solid-containing water-based pure acrylic resin is 28min, the soaking time in the described step (2) is 2.5h, and the time in the described step (3) The heat preservation time is 2.5h, and the heat preservation time in the described step (4) is 1h.

[0057] Wherein, the pumping time in the described preparation step (1) of the 65% solid-containing water-based epoxy-modified acrylic resin is 28min, the soaking time in the described step (2) is 2.5h, and the described step (3 ) in the heat preservation time is 2.5h, and the heat preservation time in the described step (4) is 1h.

[0058] The preparation method of the water-based aluminized pr...

Embodiment 3

[0060] On the basis of embodiment 2, present embodiment 3 is as a preferred embodiment of the present invention, a kind of water-based mirror back aluminized protective paint, by weight percentage, comprises following raw material:

[0061]

[0062] Wherein, the preparation of the 65% solid water-based pure acrylic resin and the 65% solid water-based epoxy-modified acrylic resin refers to Example 2.

[0063] Wherein, the preparation method of the water-based aluminized protective coating on the back of the mirror is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com