Tubular LPCVD (Low Pressure Chemical Vapor Deposition) vacuum reaction chamber

A reaction chamber and vacuum technology, applied in the direction of gaseous chemical plating, crystal growth, coating, etc., can solve the problems of unstable air flow, easy aging of sealing ring, deposition rate, inconsistent film performance, etc., and reduce the temperature of sealing surface , Excellent sealing performance, shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

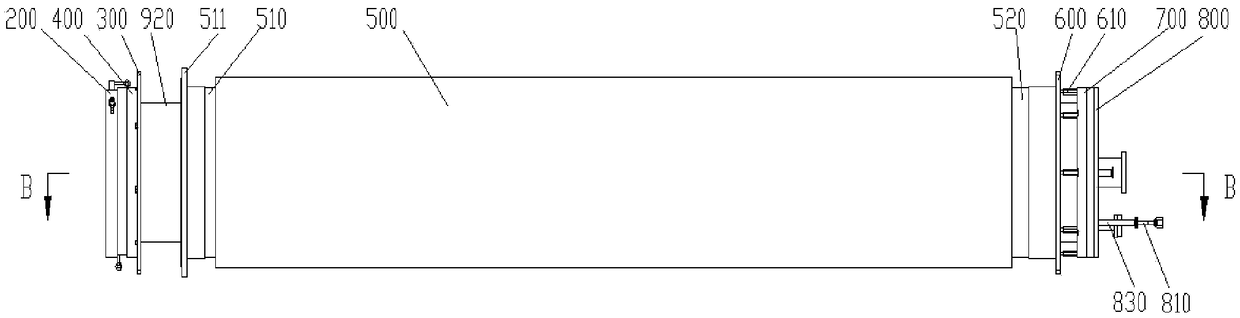

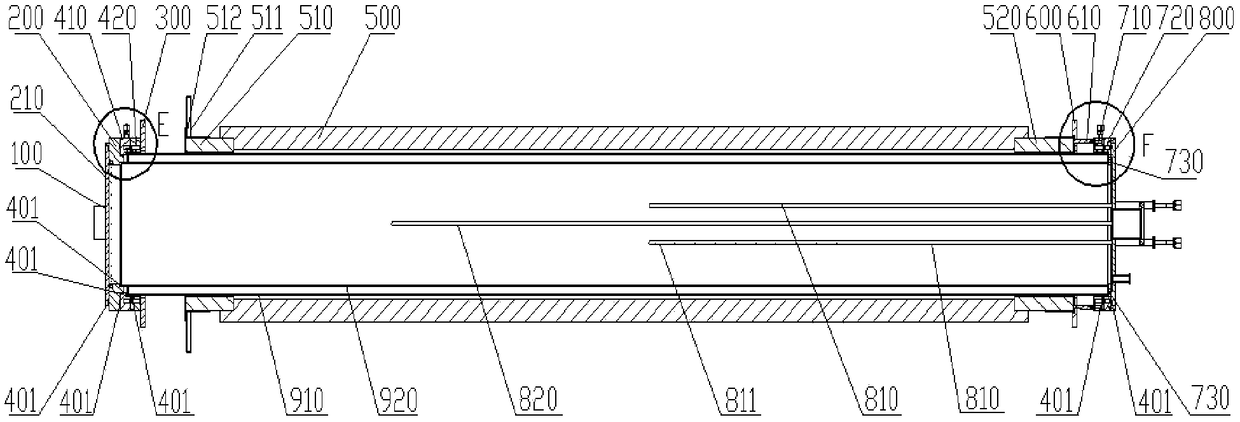

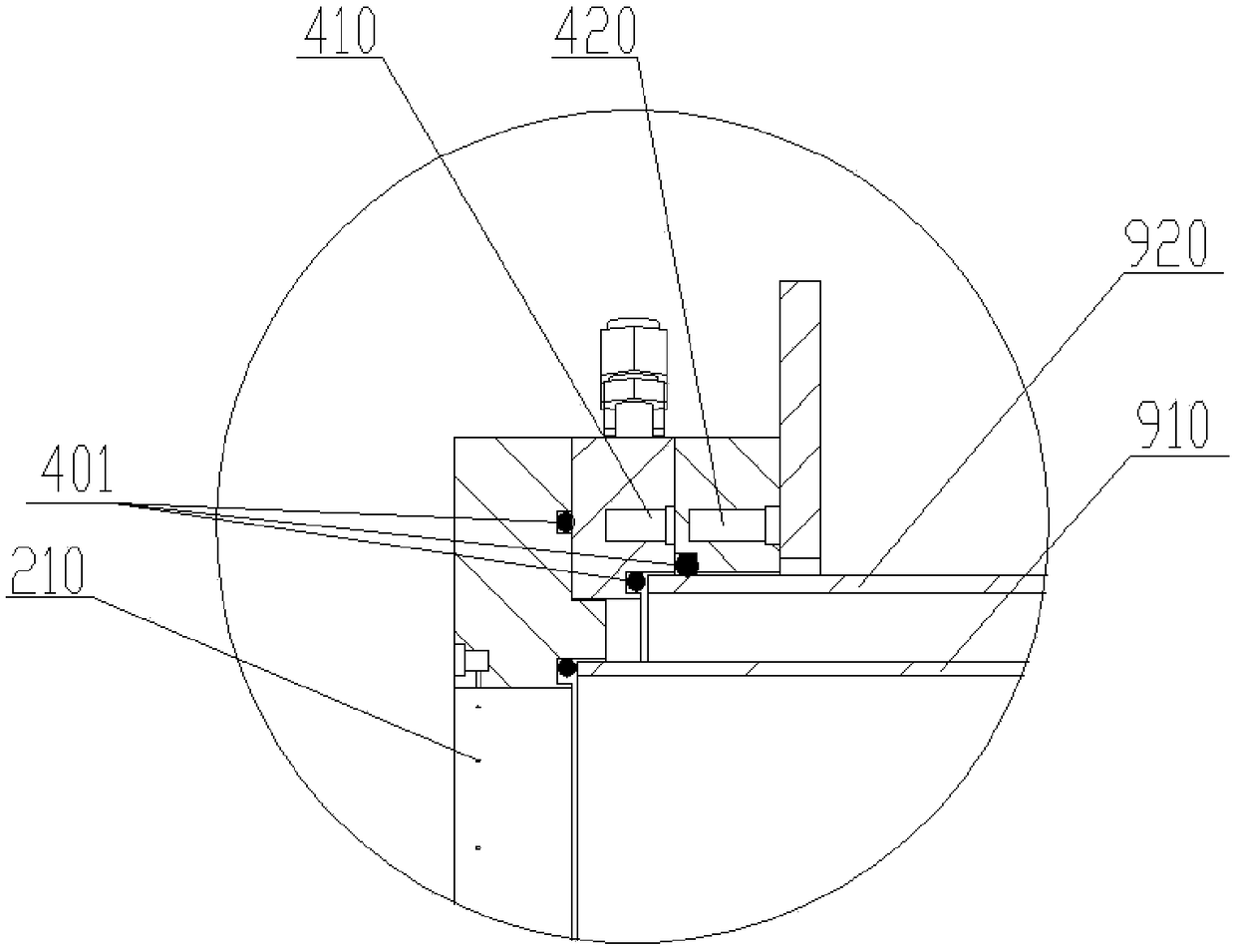

[0027] Such as Figure 1 to Figure 4 As shown, the tubular LPCVD vacuum reaction chamber of this embodiment includes a furnace door 100, a front flange 200, a front support flange 300, a front sealing assembly 400, a heating furnace body 500, a rear support flange 600, and a rear sealing assembly 700. , the tail end flange 800, the inner layer quartz tube 910 and the outer layer quartz tube 920, the outer layer quartz tube 920 is set on the outside of the inner layer quartz tube 910, the heating furnace body 500 is set on the outer layer quartz tube 920, the front support method The flange 300 and the rear support flange 600 are respectively located on the outer tube wall at the two ends of the outer layer quartz tube 920, the furnace door 100 is connected with the front end flange 200, and the front end flange 200 covers the inner la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com