A heat treatment furnace for rocking synthesis of CdZnTe polycrystalline materials

A technology of heat treatment furnace and cadmium zinc telluride, which is applied in the field of infrared detectors, can solve the problems of crystal material explosion and easy generation of holes, etc., and achieve the effects of suppressing holes, strong temperature field adjustment, and improving swing synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

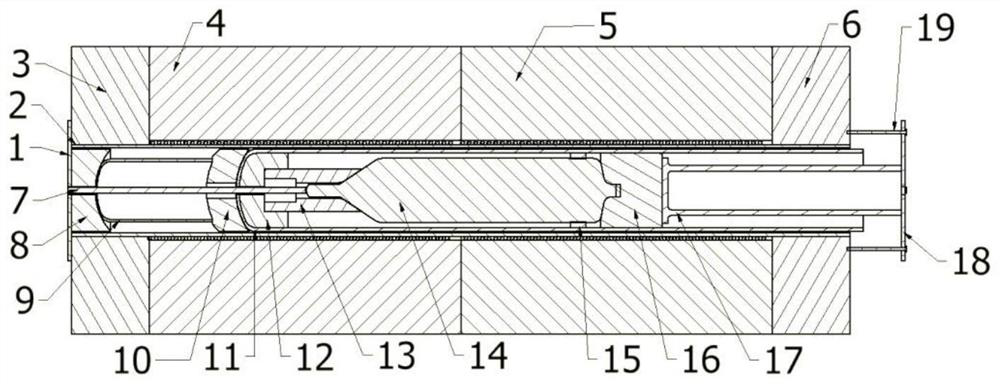

[0019] In order to solve the problem that the existing rocking synthesis furnace with single temperature zone tends to cause the crystal material to explode or produce holes when the temperature rises and falls, the present invention provides a heat treatment furnace for swinging synthesis of CdZnTe polycrystalline material. The structure of two temperature zones makes the temperature field more adjustable and can generate a certain temperature gradient. When swinging, a certain temperature gradient in the melt is conducive to melt convection, and the components are mixed more uniformly; when the temperature is lowered, a certain temperature gradient increases the crystallization driving force, effectively suppressing the hole problem of the synthesized polycrystalline material. During the swinging process of the ampoule, the compression degree of each part inside the furnace can be adjusted through the positioning nut, so that the horizontal swing range of the ampoule is ≥30°,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com