Dynamic measurement device and method for coal-oxygen composite reaction gaseous product component and coal weight

A technology for dynamic determination of gaseous products, applied in measurement devices, sampling devices, material separation, etc., can solve problems such as inability to monitor gas composition changes, experimental system errors, and single test indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

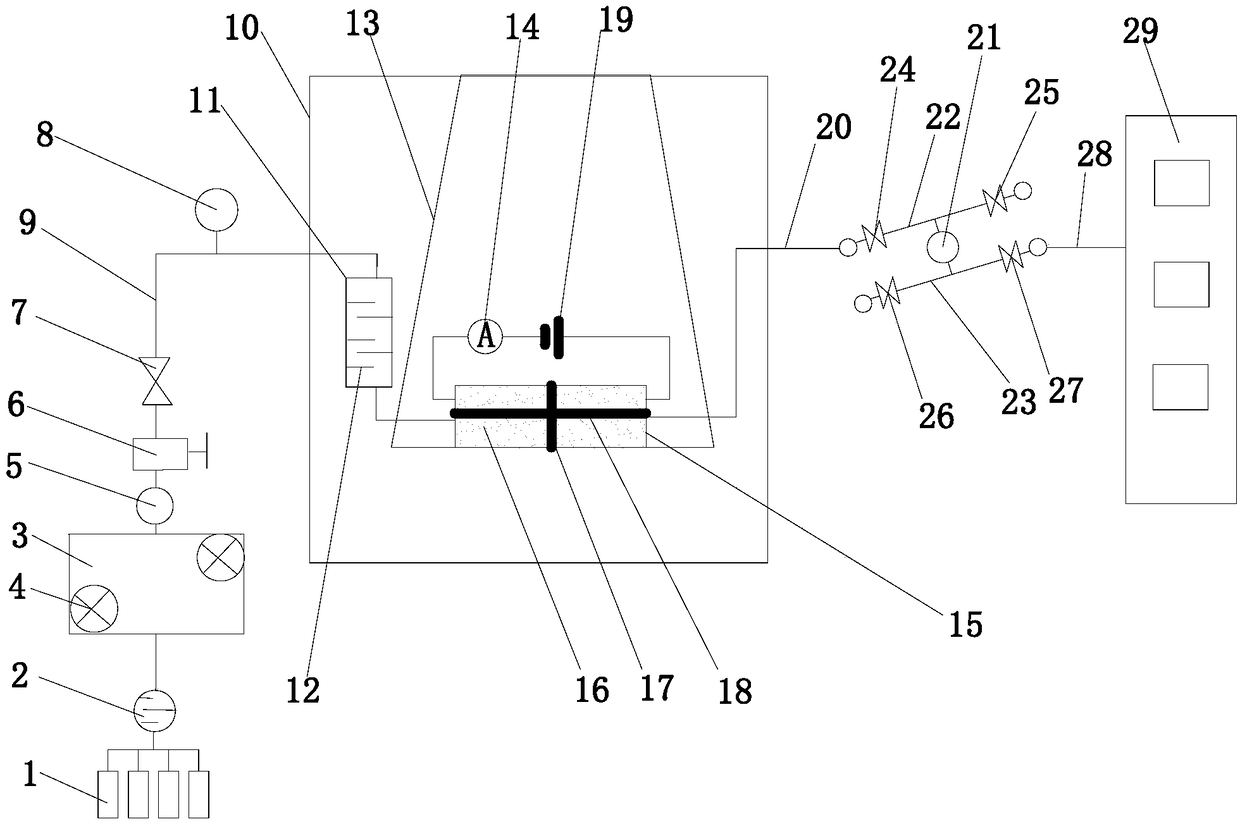

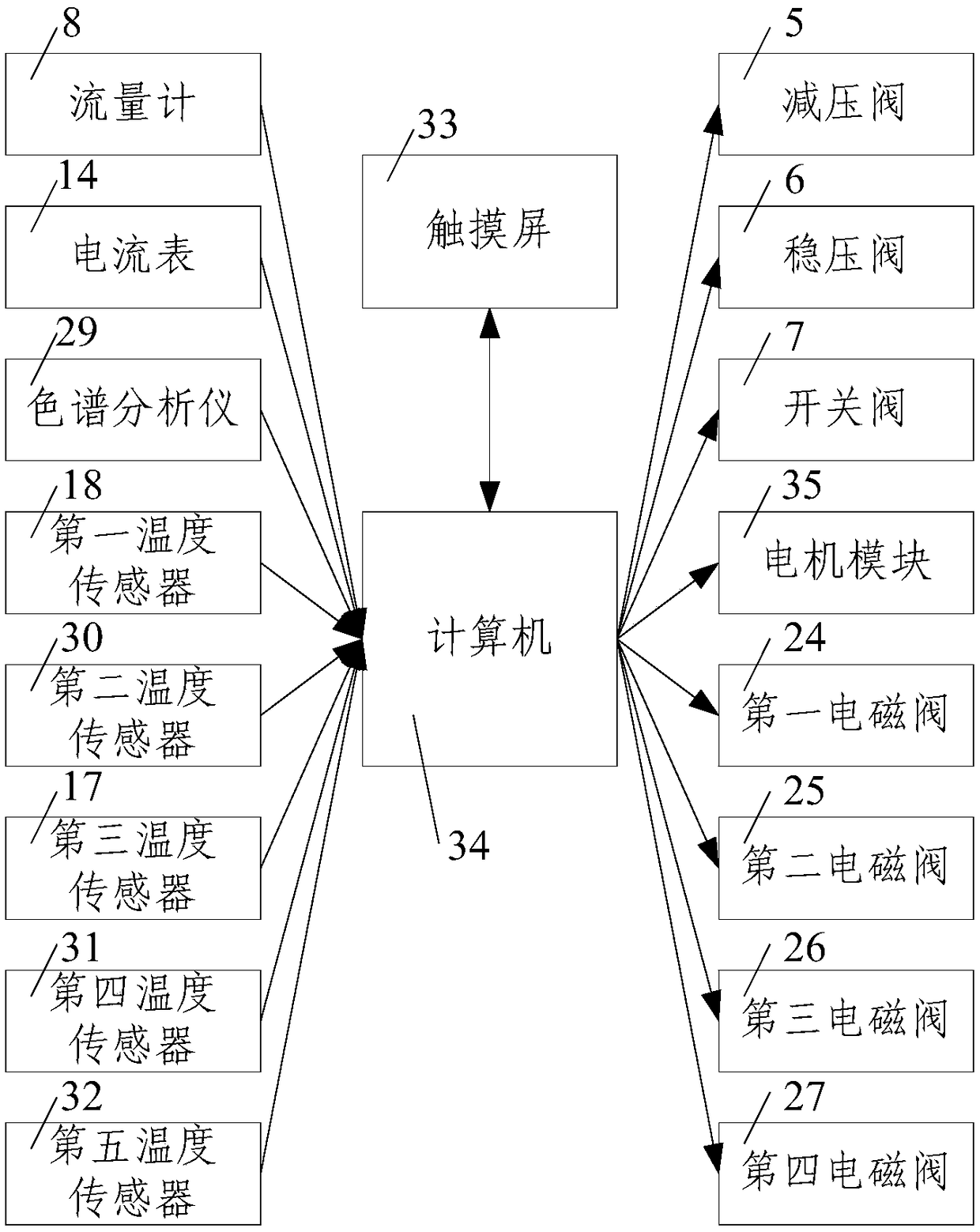

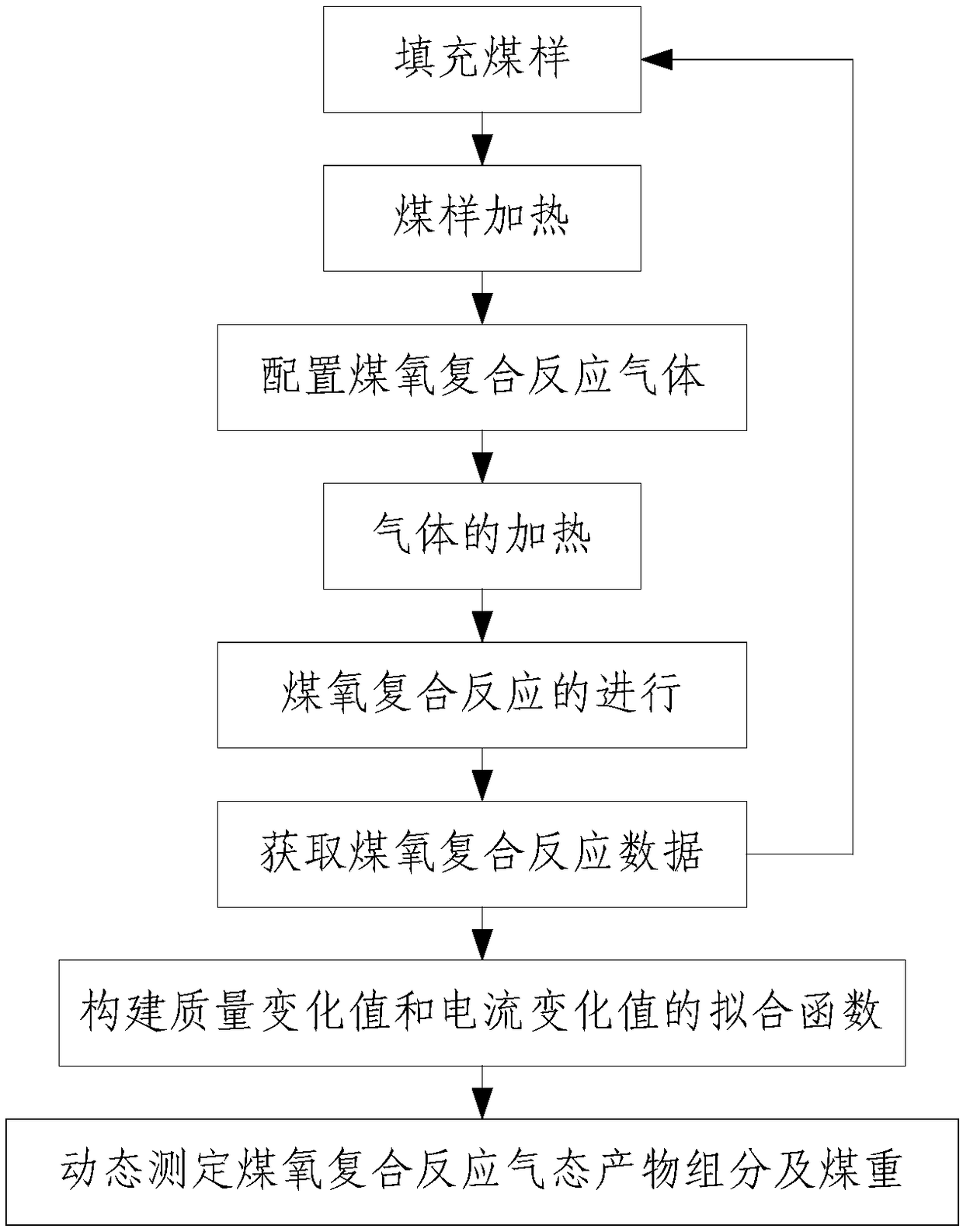

[0062] Such as figure 1 and figure 2 As shown, the gaseous product components of the coal-oxygen composite reaction and the coal weight dynamic measuring device described in the present invention include an air intake mechanism, a composite reaction mechanism, a quantitative gas-taking mechanism and a chromatographic analyzer 29 connected in sequence;

[0063] The air intake mechanism includes a high-pressure gas cylinder 1, a gas premixing container 2, a gas mixing container 3 and a switch valve 7 installed in sequence on the gas input pipeline 9. The gas premixing container 2 is a spherical structure with a rough inner surface and the gas A spoiler is welded in the premixing container 2, and a fan 4 is arranged on the diagonal of the gas mixing container 3;

[0064] Described composite reaction mechanism comprises automatic heating box 10 and is arranged on the gas heater 11 in the automatic heating box 10 and suspension bracket 13, is provided with baffle plate 12 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com