Mulberry fruit wine and preparation method thereof

A technology for fruit wine and mulberries, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, etc. The problem is to avoid excessive residual sulfur, harmonize the wine body, and solve the effect of high acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

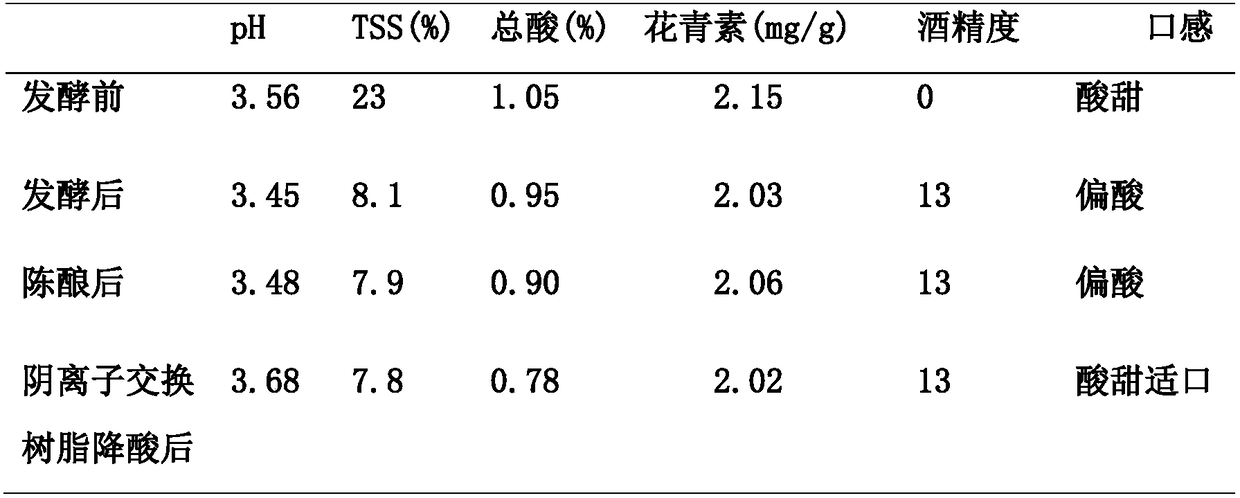

Embodiment 1

[0032] To prepare the mulberry cider:

[0033] 1. Clean, disinfect and sterilize the production equipment;

[0034] 2. Select and pick 600kg of fresh mulberries that are free from pests and diseases, rotten, and seven percent mature and above, and washed with clean water to remove dust and foreign matter on the skin;

[0035] 3. Squeeze with a screw press, repeat the squeeze twice, and mix the juice obtained from the two squeezes to get 420kg;

[0036] 4. Add pectinase 40mg / L to enzymolyze for 3 hours at room temperature. After enzymolysis, use a refractometer to measure the soluble solids TSS of the juice to 9.3%, add sugar to dissolve, adjust the soluble solids TSS content of the juice to 23%, and heat to 65-70°C, keep it warm for 30 minutes to sterilize, then transfer the fermented fruit juice to a fermenter, and cool down to 25°C.

[0037] 5. Weigh 0.1g / L of yeast to activate, then inoculate into the fermenter, add 10mg / L of lactic acid bacteria, control the fermentation...

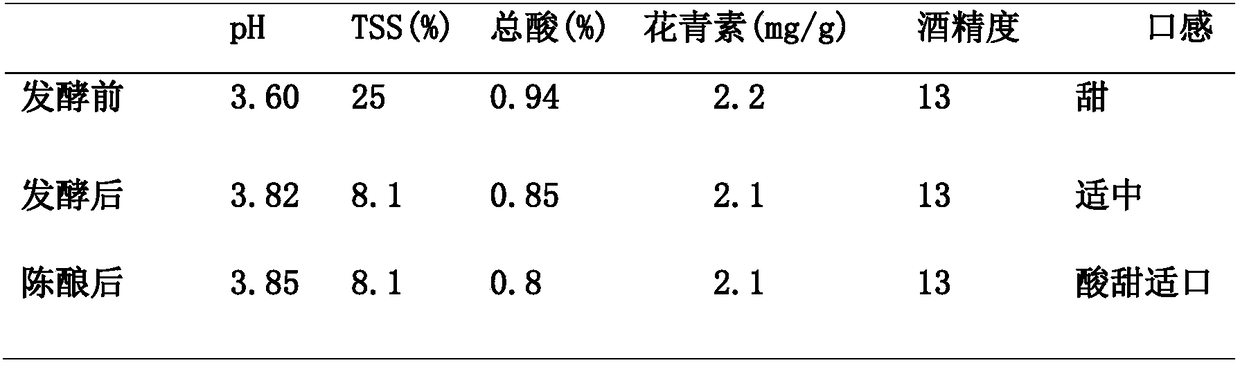

Embodiment 2

[0046] To prepare the mulberry cider:

[0047] Steps 1-3: Same as Example 1.

[0048] 4. Add pectinase 50mg / L to enzymolyze for 2.5h at room temperature. After enzymolysis, use a refractometer to measure the soluble solids TSS of the juice to 9.6%, add sugar to dissolve, and adjust the soluble solids TSS content of the juice to 25%. Heat to 65-70°C, keep warm for 30 minutes to sterilize, then transfer the fermented fruit juice to a fermenter, and cool down to 25°C.

[0049] 5. Weigh 0.1g / L of yeast to activate, then inoculate into the fermenter, add lactic acid bacteria 10mg / L, control the fermentation temperature at 20°C, open the fermenter once a day to stir the fermentation liquid, each time for 30min, regularly check the TSS content until After the fermentation continued for 8 days, the TSS content did not change any more, and the fermentation ended, and the mulberry fruit fermentation liquid was obtained;

[0050] 6. Cooling treatment, taking samples to determine the ac...

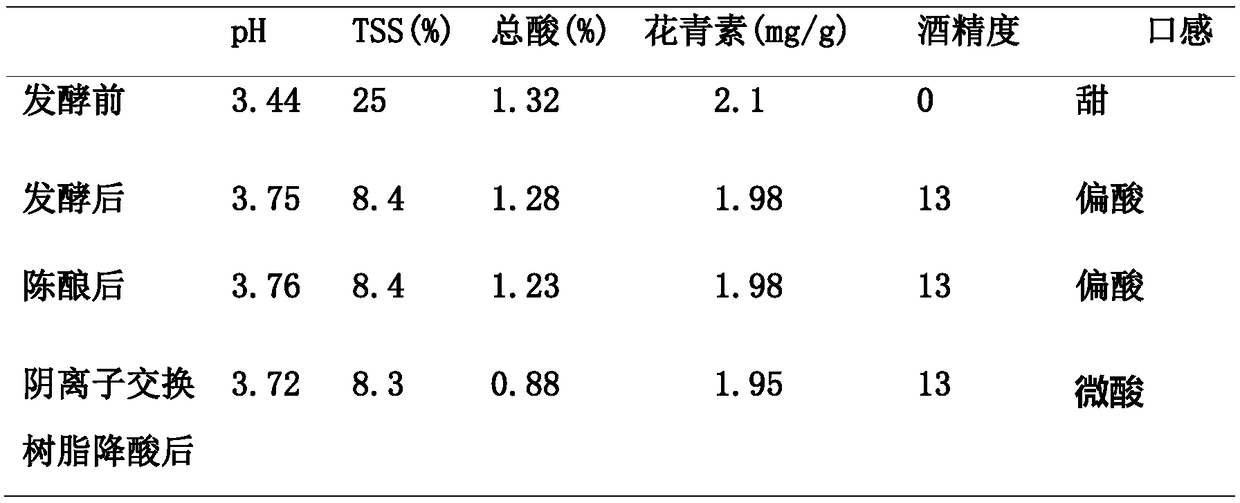

Embodiment 3

[0057] To prepare the mulberry cider:

[0058] 1. Clean, disinfect and sterilize the production equipment;

[0059] 2. Select and pick 600kg of fresh mulberries that are free from pests and diseases, rotten, and seven percent mature and above, and washed with clean water to remove dust and foreign matter on the skin;

[0060] 3. Squeeze with a screw press, the juice yield is 65%, and 390kg of juice is obtained;

[0061] 4. Add pectinase 40mg / L to enzymolyze for 2.5 hours at room temperature. After enzymolysis, use a refractometer to measure the soluble solids TSS of the fruit juice to be 9.1%, add sugar to dissolve, and adjust the soluble solids TSS content of the fruit juice to 25%. Heat to 65-70°C, keep warm for 30 minutes to sterilize, then transfer the fermented fruit juice to a fermenter, and cool down to 25°C.

[0062] 5. Weigh 0.1g / L of yeast to activate, then inoculate into the fermenter, add lactic acid bacteria 10mg / L, control the fermentation temperature at 20°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com