Feed formula capable of producing poultry eggs with high astaxanthin content and processing technology of feed formula

A technology of feed formula and processing technology, which is applied in the field of feed formula and processing technology that can produce poultry eggs with high content of astaxanthin. Uneven water content and other problems, to achieve the effect of improving digestion utilization, improving nutritional value and digestibility, and reducing harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

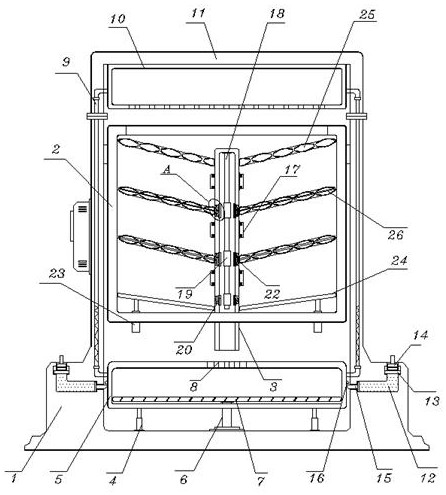

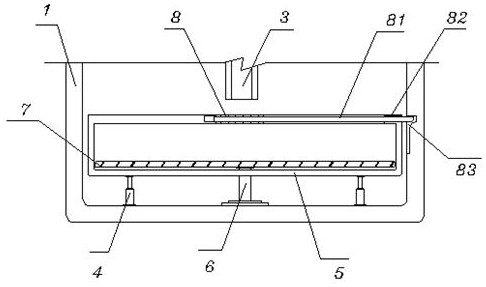

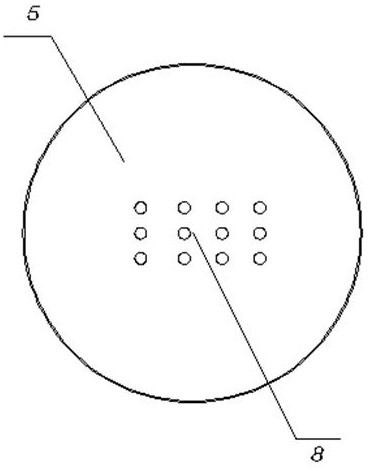

[0038] see Figure 1-6 , the process includes the following steps:

[0039] S1: Configure according to the astaxanthin feed formula and the probiotic formula respectively;

[0040] S11: The astaxanthin feed formula includes the following components: corn flour, soybean meal, wheat bran, fish meal, mycelium protein, stone powder, salt, full-fat Haematococcus pluvialis wall-broken powder, defatted Haematococcus pluvialis powder, soybean oil, dry marigold powder and premixes;

[0041] S12: The probiotic formula includes the following components: Bacillus, Lactobacillus and yeast;

[0042] S2: Combine corn flour, soybean meal, wheat bran, fish meal, mycelium protein, stone powder, salt, full-fat Haematococcus pluvialis wall breaking powder, defatted Haematococcus pluvialis powder, soybean oil, and marigold in the above step S11 Dry powders and premixes are crushed and premixed to produce raw materials:

[0043] S3: Add the bacillus, lactobacillus and yeast in the above step S1...

Embodiment 2

[0048] see figure 1 and Figure 5-6 middle,

[0049] The processing technology includes the following steps:

[0050] S1: Configure according to the astaxanthin feed formula and the probiotic formula respectively;

[0051] S11: The astaxanthin feed formula includes the following components: corn flour, soybean meal, wheat bran, fish meal, mycelium protein, stone powder, salt, full-fat Haematococcus pluvialis wall-broken powder, defatted Haematococcus pluvialis powder, soybean oil, dry marigold powder and premixes;

[0052] S12: The probiotic formula includes the following components: Bacillus, Lactobacillus and yeast;

[0053] S2: Combine corn flour, soybean meal, wheat bran, fish meal, mycelium protein, stone powder, salt, full-fat Haematococcus pluvialis wall breaking powder, defatted Haematococcus pluvialis powder, soybean oil, and marigold in the above step S11 Dry powders and premixes are crushed and premixed to produce raw materials:

[0054] S3: Add the bacillus, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com