High-viscosity anti-corrosive belt suitable for marine atmospheric environment and preparation method and application thereof

A marine atmosphere and anti-corrosion technology, used in textiles, papermaking, fiber processing, etc., can solve problems such as protection of non-shaped steel structures, and achieve the effect of enhancing corrosion inhibition effect, inhibiting occurrence rate, and reducing corrosion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

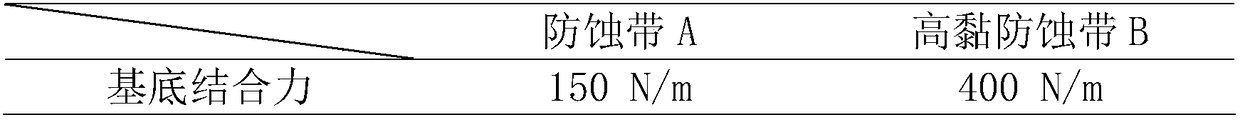

[0023] High-viscosity anti-corrosion tape and substrate bonding force test:

[0024] (1) Paste material A for preparing anti-corrosion tape: 28% of industrial linseed oil, 3% of corrosion inhibitor, 8% of nano-alumina, 61% of flame-retardant inorganic filler;

[0025] Paste material B for preparing high-viscosity anti-corrosion tape: 28% of high-viscosity modified polymerized linseed oil, 3% of corrosion inhibitor, 8% of nano-alumina, and 61% of flame-retardant inorganic filler.

[0026] The corrosion inhibitor is a mixture of tannic acid, calcium stearate, sodium silicate and ethanolamine, and its mass fraction ratio range is 1:5:0.1:0.01; the flame-retardant inorganic filler is aluminum hydroxide, magnesium hydroxide The mixture with organic bentonite has a mass fraction ratio of 3:2:1; the insulating agent is nano-alumina with a particle diameter of 15 nanometers.

[0027] The high-viscosity modified polymerized linseed oil is prepared by pre-oxidation and pre-polymerizati...

Embodiment 2

[0034] High viscosity corrosion resistance test:

[0035] (1) Preparation of paste material C: 30% of high-viscosity modified polymerized linseed oil, 70% of flame-retardant inorganic filler;

[0036] Prepare paste material D: 30% of high-viscosity modified polymerized linseed oil, 3% of corrosion inhibitor, 8% of nano-alumina, and 59% of flame-retardant inorganic filler.

[0037] The corrosion inhibitor is a mixture of tannic acid, calcium stearate, sodium silicate and ethanolamine, and its mass fraction ratio range is 1:5:0.1:0.01; the flame-retardant inorganic filler is aluminum hydroxide, magnesium hydroxide The mixture with organic bentonite has a mass fraction ratio of 3:2:1; the insulating agent is nano-alumina with a particle diameter of 15 nanometers.

[0038] The high-viscosity modified polymerized linseed oil is prepared by pre-oxidation and pre-polymerization of industrial linseed oil. Heat the industrial linseed oil to 120°C in the air atmosphere, stir for 8-10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com