Power battery energy storage type electric workover rig

A technology of electric workover rig and power battery, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of high energy consumption, high noise, waste of electric workover rig operating power and traveling power configuration, etc., and achieves an optimized structure. , reduce the effect of power configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

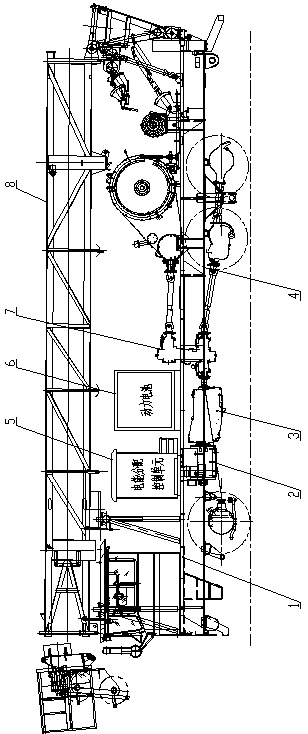

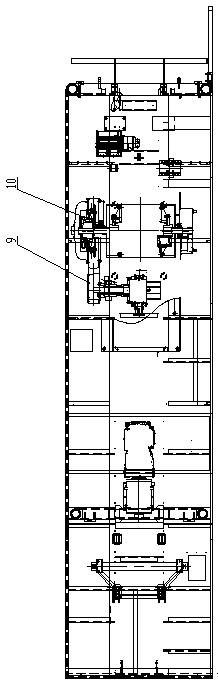

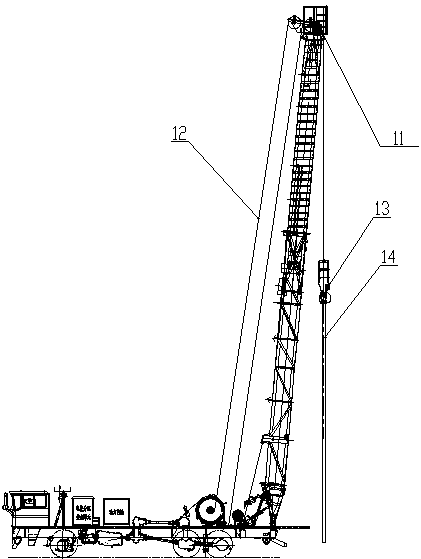

[0022] Such as Figure 1-4 As shown, there is an AC variable frequency motor 2 below the special chassis 1 for workover rigs, a gearbox 3 is installed behind the AC variable frequency motor 2, and a power distribution control unit 5 above the AC variable frequency motor 2, and a power battery pack behind the power distribution control unit 5 6. The transfer case 7 is installed in the middle of the special chassis 1 of the workover rig. The rear of the special chassis of the workover rig is equipped with a winch skid 4, an angle transmission box 9, a drum 10, a chain box 18, and a mast 8 is located above the drum 10, and the drum 10 A wire rope 12 is wound on it, a pulley 11 and a traveling block hook 13 are installed on the derrick 8.

[0023] The special chassis 1 for workover rigs is equipped with an electric energy distribution control unit 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com