Visual inspection method and apparatus for secondary printing precision of crystalline silicon photovoltaic solar cell electrodes

A solar cell and visual inspection technology, which is applied in circuits, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve the problems of increasing equipment costs, increasing the amount of image processing operations, etc., achieving high robustness and reducing grid lines. The effect of testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

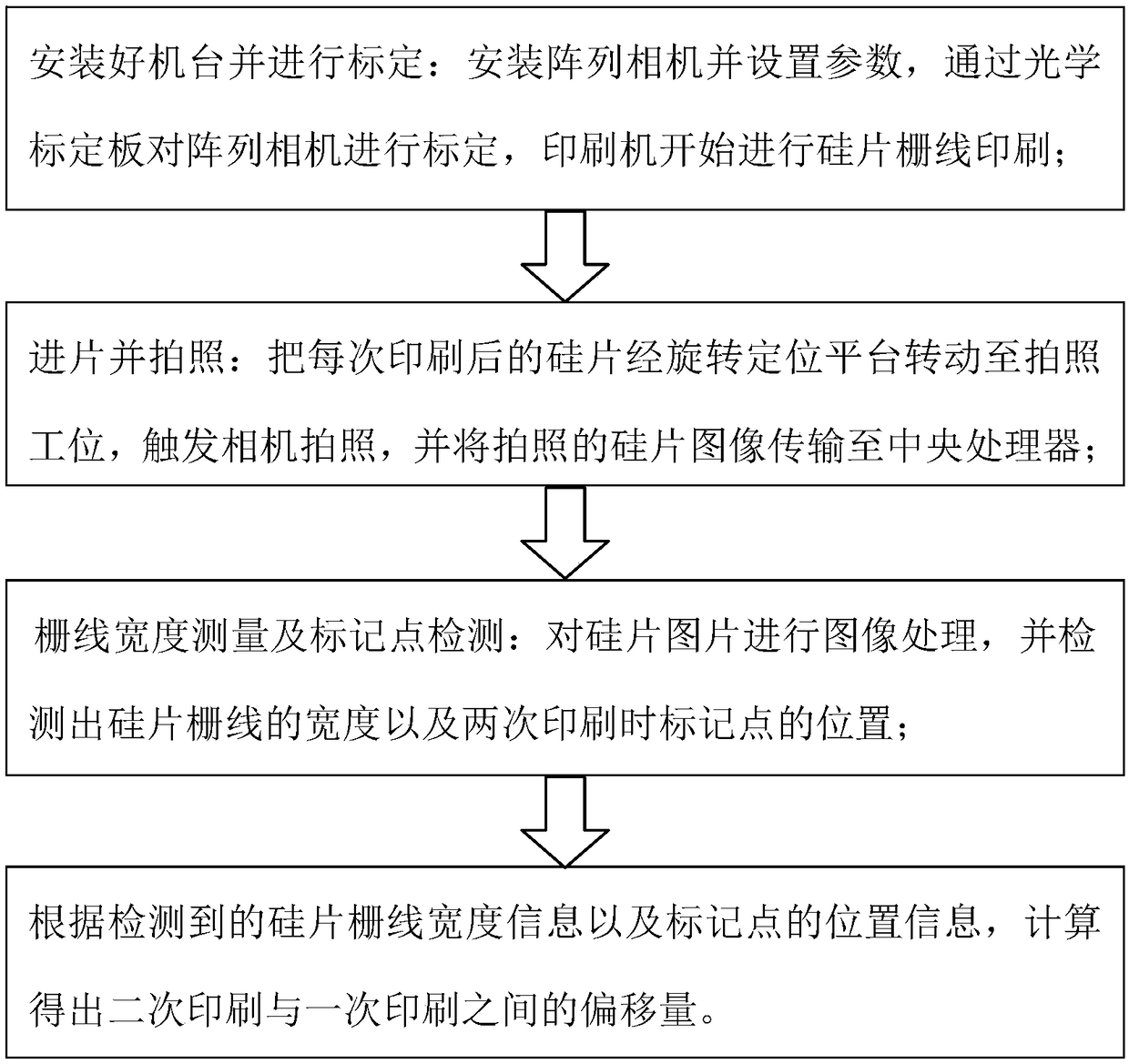

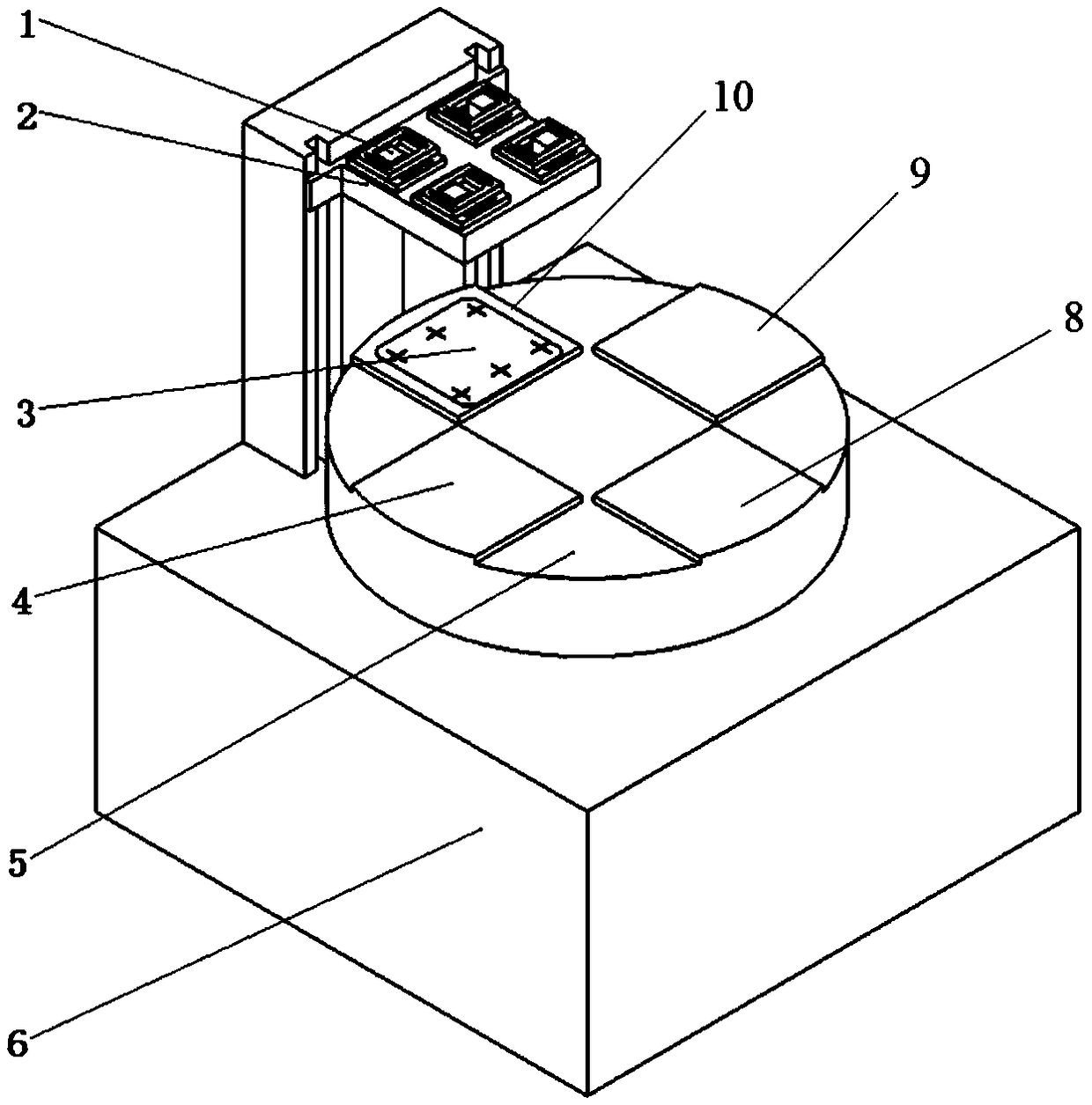

[0053] Such as figure 1 As shown, a kind of crystalline silicon photovoltaic solar cell electrode secondary printing accuracy visual inspection method of the present invention comprises the following steps:

[0054] (1) Install the array camera and set the parameters, and calibrate the cameras in the camera array by customizing the optical calibration plate and combining with the calibration algorithm. After the calibration is completed, take out the optical calibration plate; the printing machine starts to print the silicon wafer grid lines;

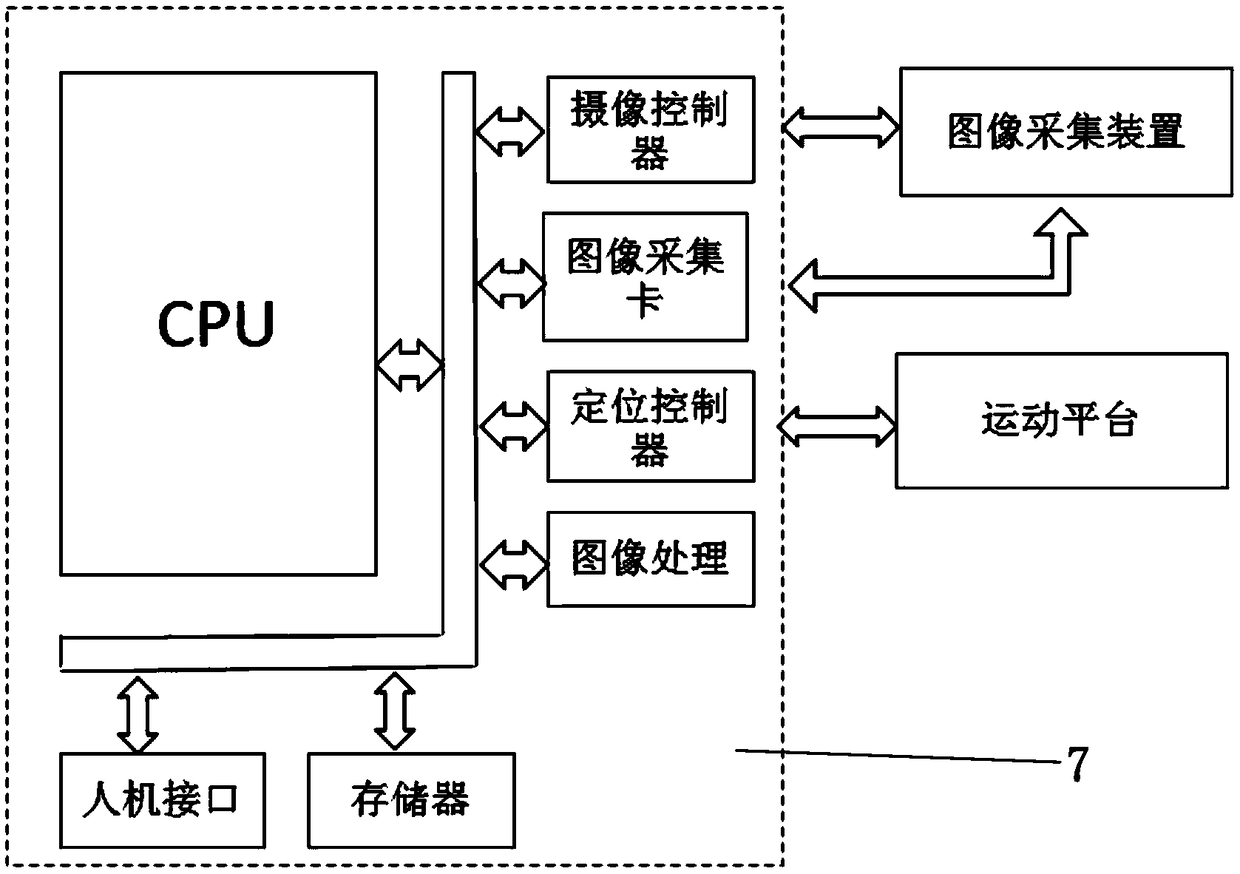

[0055] (2) After each printing of the printing machine, the printed silicon wafer is rotated 90 degrees by the rotating positioning platform and sent to the photographing station under the array camera, and the array camera is triggered to take pictures at the same time, and then the photographed silicon wafer image is transmitted to the central processing device;

[0056] (3) the central processing unit extracts the edge of the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com