Silk fibroin-dopamine-E7 oligopeptide compound stent and preparation method and application thereof

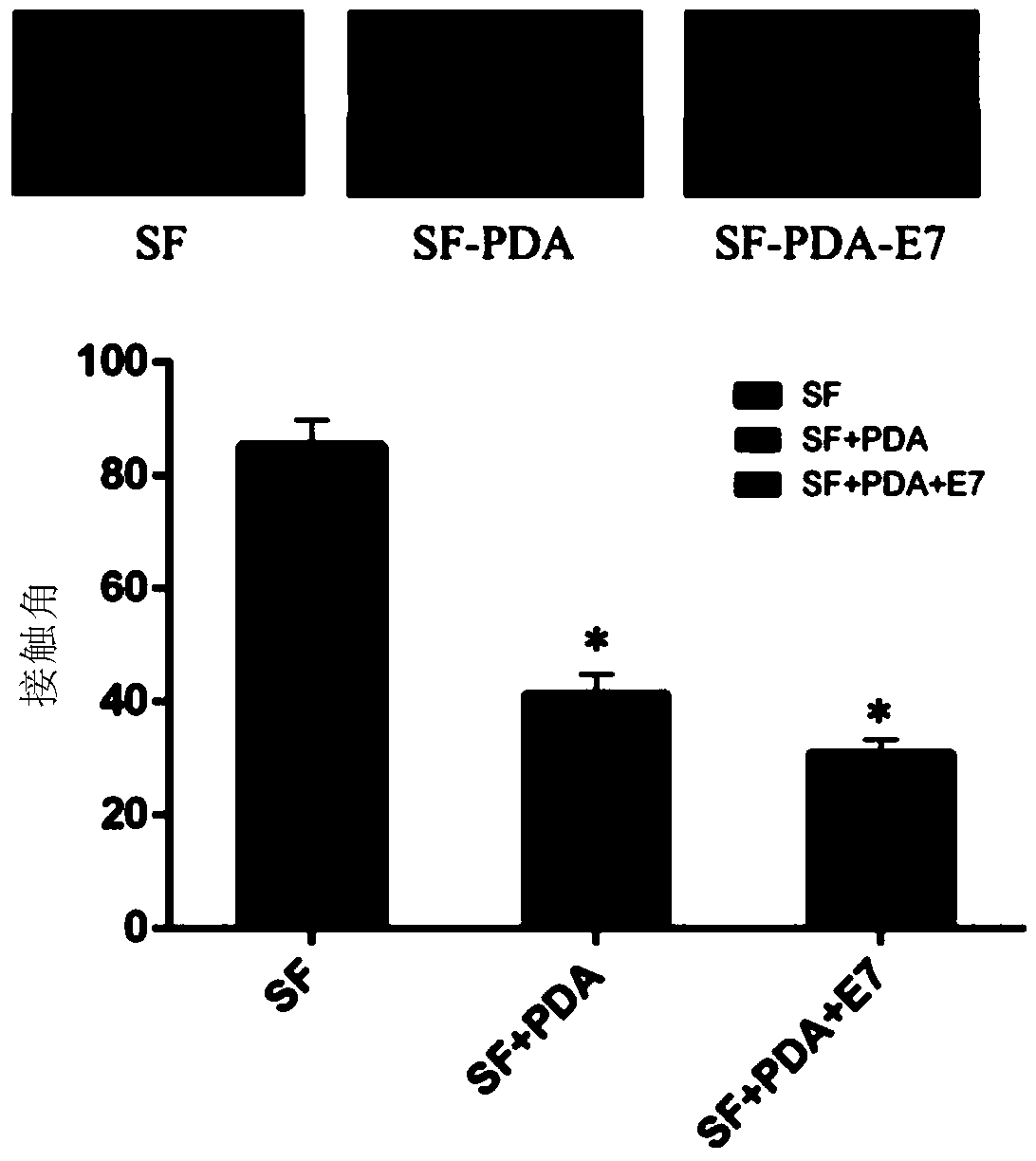

A technology of silk fibroin and composite scaffold, which is applied in pharmaceutical formulations, coatings, pharmaceutical sciences, etc., can solve the problem of weak osteoinductive performance of silk protein, accelerate osteogenic differentiation, improve hydrophilicity, and promote cell adhesion. The effect of adhering to proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of the scaffold

[0059] First, dissolve 8g silk protein (SF) in 80ml hexafluoroisopropanol mixed solvent to form a 10% (W / V) solution, draw the silk protein mixture into a 10ml injection syringe, and inject 1.5-2ml of it through a micro-injection pump. Propelling at a rate of / h, the inner diameter of the front needle is a stainless steel flat-head dispensing needle of 0.8mm. During the electrospinning process, the voltage was controlled at 15-20kV, and the distance from the needle to the receiver was 15-20cm. The rotating speed of the drum collector was 300-500 times per minute, and the electrospun fibers were collected on aluminum foil paper and dried in vacuum to obtain SF scaffolds.

[0060] Dissolve dopamine in Tris-buffer, and immerse 8g silk protein electrospinning scaffold (SF scaffold) in 20ml dopamine solution (4mg / ml) for 12 hours, and form a polydopamine (PDA) deposition layer after fully oxidizing and self-polymerizing. Get the SF-PDA holder....

Embodiment 2

[0063] Preparation of the scaffold

[0064] The experimental procedure is the same as in Example 1, except that the voltage in the electrospinning process is changed to 20-25kv.

[0065] First, dissolve 8g silk protein (SF) in 80ml hexafluoroisopropanol mixed solvent to form a 10% (W / V) solution, draw the silk protein mixture into a 10ml injection syringe, and inject 1.5-2ml of it through a micro-injection pump. Propelling at a rate of / h, the inner diameter of the front needle is 0.8mm stainless steel flat dispensing needle. During the electrospinning process, the voltage was controlled at 20-25kV, and the distance from the needle to the receiver was 15-20cm. The rotating speed of the drum collector was 300-500 times per minute, and the electrospun fibers were collected on aluminum foil paper and dried in vacuum to obtain SF scaffolds.

[0066] Dissolve dopamine in Tris-buffer, and immerse 8g silk protein electrospinning scaffold (SF scaffold) in 20ml dopamine solution (4mg / m...

Embodiment 3

[0069] Preparation of the scaffold

[0070] The experimental procedure is the same as that in Example 1, except that the concentration of the dopamine solution immersed in the silk protein electrospinning scaffold (SF scaffold) is 2 mg / ml.

[0071] First, dissolve 8g silk protein (SF) in 80ml hexafluoroisopropanol mixed solvent to form a 10% (W / V) solution, draw the silk protein mixture into a 10ml injection syringe, and inject 1.5-2ml of it through a micro-injection pump. Propelling at a rate of / h, the inner diameter of the front needle is a stainless steel flat-head dispensing needle of 0.8mm. During the electrospinning process, the voltage was controlled at 15-20kV, and the distance from the needle to the receiver was 15-20cm. The rotating speed of the drum collector was 300-500 times per minute, and the electrospun fibers were collected on aluminum foil paper and dried in vacuum to obtain SF scaffolds.

[0072] Dissolve dopamine in Tris-buffer, and immerse 8g silk prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com