Online melting carbon fiber reinforced aluminum-magnesium composite plate cast rolling molding device and method

A technology of forming equipment and clad plate, applied in metal processing equipment, metal rolling, metal rolling and other directions, can solve the problems of unstable continuous fiber reinforced aluminum-magnesium clad plate process, poor quality of clad plate, low production efficiency, etc. Achieve the effect of compact structure, high interface bonding strength and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description with reference to the accompanying drawings. It should be understood that the present invention can have various changes in different embodiments, which do not depart from the protection scope of the present invention, and the descriptions and illustrations therein are essentially for illustrative purposes, not for Limit the invention.

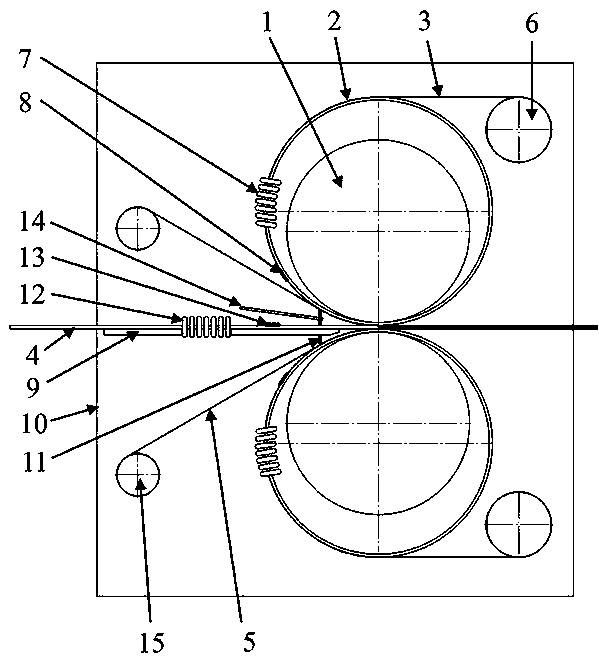

[0019] Such as figure 1 As shown, an online melting carbon fiber reinforced aluminum-magnesium composite plate casting-rolling molding equipment includes: rolling mill 1, roll sleeve 2, online heating system, gas protection system, raw material rack, skin plate 3, core plate 4, carbon fiber cloth 5 , It is characterized in that the skin plate 3 is wound on the roller sleeve 2, and the skin plate raw material roll 6 is located on the side of the rolling mill. The purpose is to increase the contact leng...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap