A kind of sulphoaluminate cement and preparation method thereof

A technology of sulphoaluminate cement and cement clinker, which is applied in the direction of cement production, etc., can solve the problems of low solubility or dissolution rate of external components, difficulty in mixing uniformly, and unstable performance, so as to avoid mismatching release rate, Avoids uneven mixing and facilitates quality control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

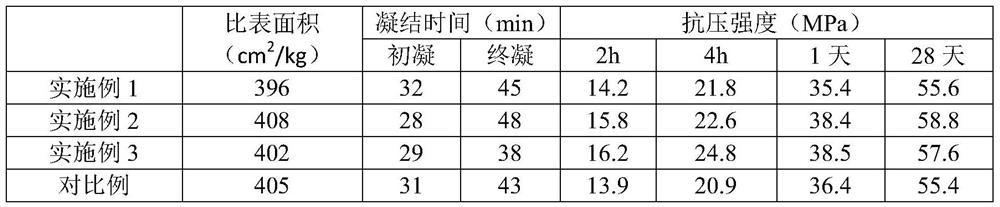

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of sulphoaluminate cement, it specifically comprises the following steps:

[0033] (1) selecting raw materials of sulphoaluminate cement, wherein the raw materials include substances containing lithium elements, grinding the raw materials to obtain raw meal powder; then calcining at 1200-1350° C. for 30 minutes to obtain cement clinker;

[0034] (2) mixing the cement clinker with anhydrite and grinding to obtain sulphoaluminate cement;

[0035] In mass percentage, the cement clinker includes:

[0036] Anhydrous calcium sulfoaluminate: 30-80%, dicalcium silicate: 10-40%, ferrite minerals: 5-20%, free gypsum: 0-15%, perovskite: 0-5%, free Calcium Oxide: 0-3% and Lithium Oxide: 0.06-0.8%.

[0037] The present invention does not specifically limit the raw materials of sulphoaluminate cement. The raw materials for the production of conventional sulphoaluminate cement are preferred. The raw materials of conventional sulpho...

Embodiment 1

[0064] A preparation method of sulphoaluminate cement, comprising the following steps:

[0065] (1) With limestone, bauxite, anhydrite, lithium slag as raw materials, the concrete components of each raw material are shown in Table 1, mixed by 60 parts of limestone, 28 parts of bauxite, 8 parts of anhydrite, and 4 parts of lithium slag, Grind into raw meal powder with a laboratory ball mill;

[0066] (2) Stir the raw meal powder with 6-8% water evenly, press it into a raw meal cake, and dry it;

[0067] (3) Pre-burn the raw cake in a muffle furnace at 950°C for 30 minutes, then transfer it to a high-temperature electric furnace at 1300°C, keep it warm for 1 hour, take it out, and cool it to room temperature by wind to obtain clinker;

[0068] (4) Mix clinker and anhydrite at a ratio of 85:15, and grind until the specific surface area is 400cm2 / kg to obtain cement.

[0069] Table 1 raw material chemical composition (%)

[0070] components loss SiO 2

Embodiment 2

[0072] A preparation method of sulphoaluminate cement, comprising the following steps:

[0073] (1) With limestone, bauxite, and desulfurized gypsum as main raw materials, industrial grade lithium carbonate and borax are used as additives. The specific components of each raw material and additive are shown in Table 2; 0.5 part, 0.5 part of lithium carbonate, 0.2 part of borax are mixed, and then ground together into raw meal powder;

[0074] (2) Stir the raw meal powder with 6-8% water evenly, press it into a raw meal cake, and dry it;

[0075] (3) Pre-burn the raw cake in a muffle furnace at 950°C for 30 minutes, then transfer it to a high-temperature electric furnace at 1280°C, keep it warm for 1 hour, take it out, and cool it to room temperature by wind blowing to obtain clinker;

[0076] (4) Mix clinker and anhydrite at a ratio of 84:16, and grind until the specific surface area is 400±20cm2 / kg to obtain cement.

[0077] Table 2 raw material chemical composition (%)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com